Radiating device for laser

A technology for heat sinks and lasers, applied in lasers, laser parts, phonon exciters, etc., can solve the problems affecting the quality and power of laser beams, the development of laser miniaturization, the speed of convection is not fast enough, the convection area is not large enough, etc. The problem is to achieve the effect of obvious heat conduction effect, obvious convection effect and good convection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical implementation process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

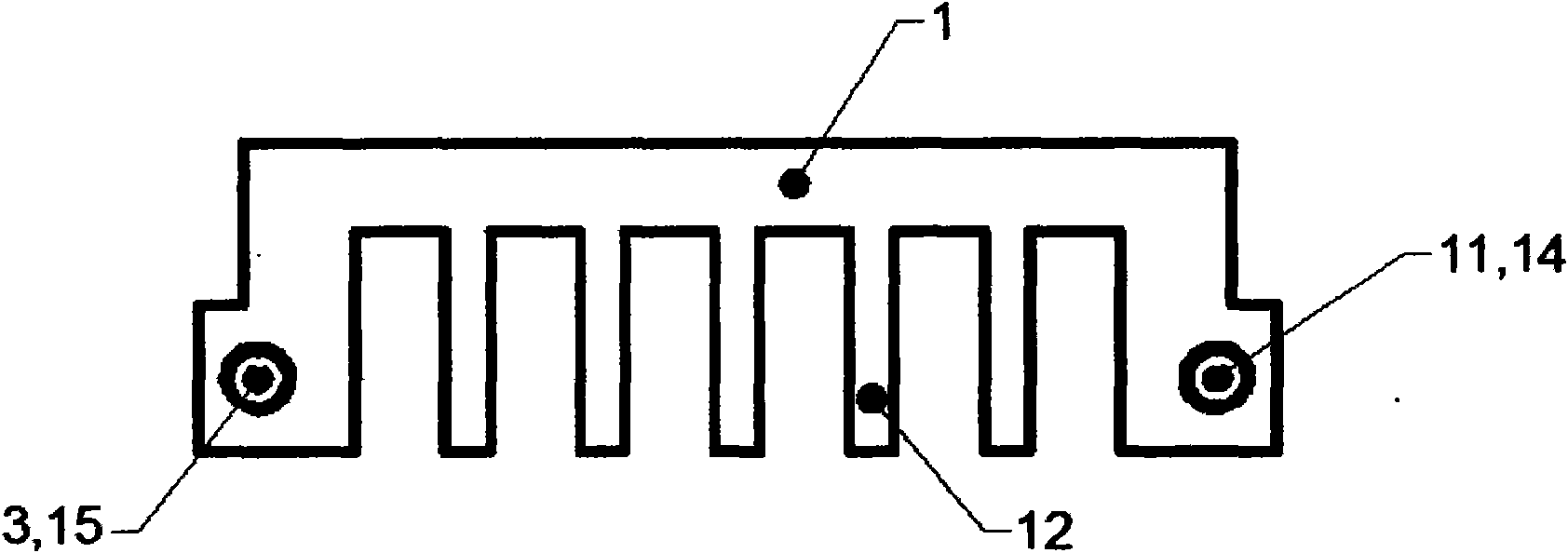

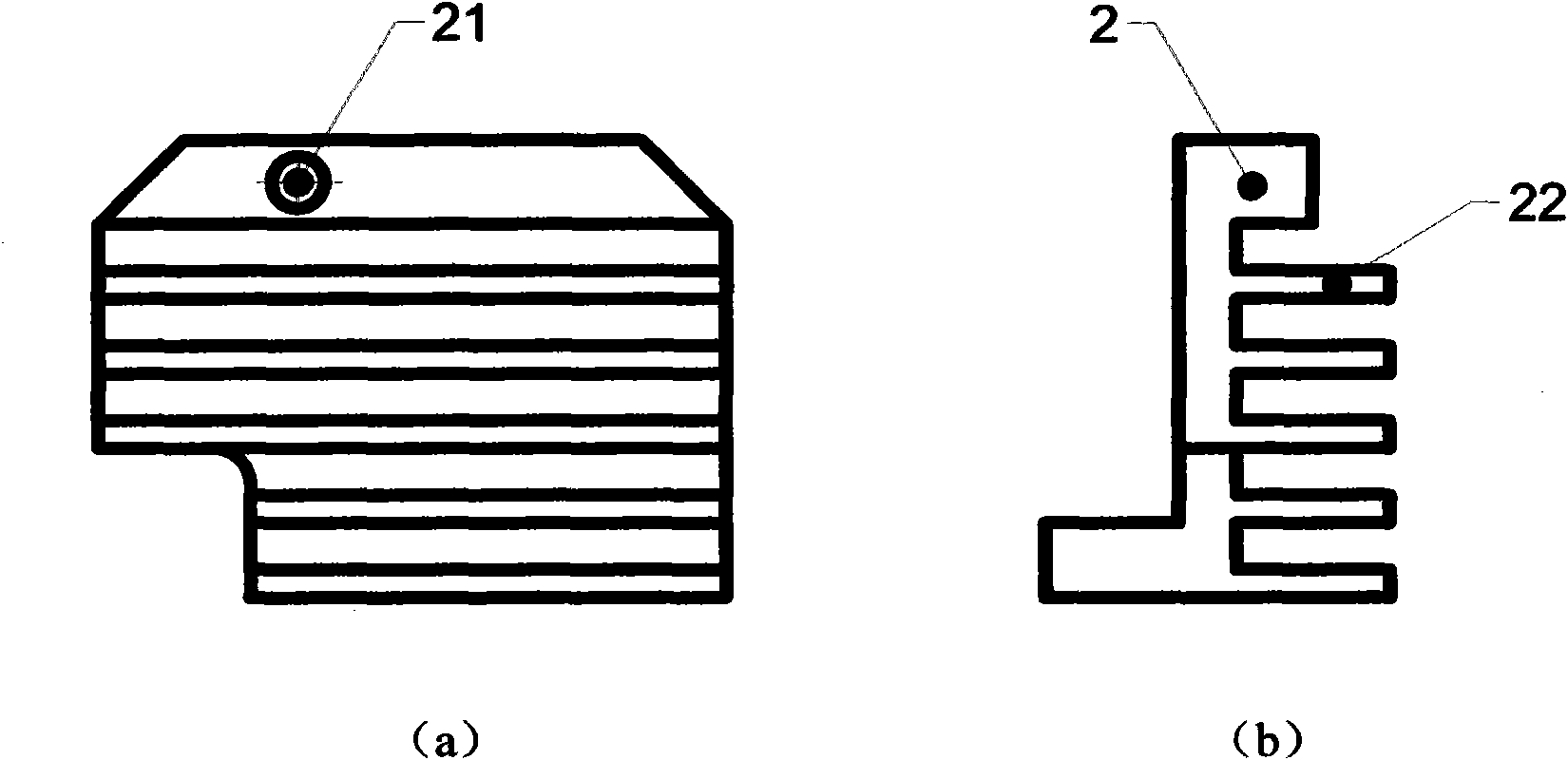

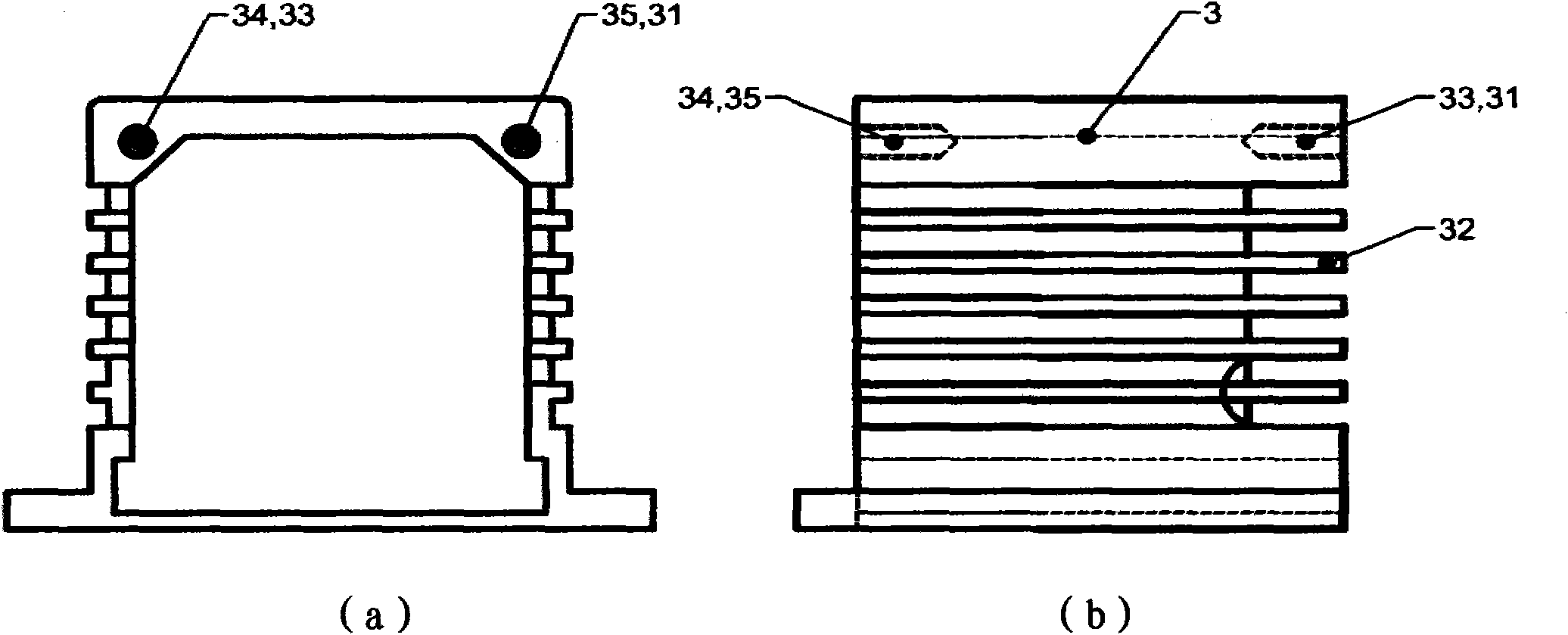

[0028] see Figure 1 to Figure 5 As shown, a heat dissipation device for a laser includes a fan, and also includes a heat sink 2, the heat sink 2 is installed at the tail of a base plate 1, the base plate 1 is inserted into an outer shell 3, and is installed in front of the outer shell 3 A front end cover 4, the fan 5 is installed behind the outer casing 3.

[0029] Further, the bottom plate 1 includes a first groove structure 12 .

[0030] Further, the heat sink 2 includes a second groove structure 22 .

[0031] Further, the front cover 4 also has a laser transmission hole 41 .

[0032] Further, the front cover 4 includes a second comb structure 42 .

[0033] Further, the outer casing 3 includes a first comb structure 32 .

[0034] Further, in order to enable the heat sink 2 to be well ventilated, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com