Combination machine forming by automatic assembly and injection molding of RCA connectors

A technology of injection molding compounding and automatic assembly, applied in the field of compound machines, can solve the problems of low work efficiency and high cost, and achieve the effects of reducing cost, improving work efficiency and reasonable process control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

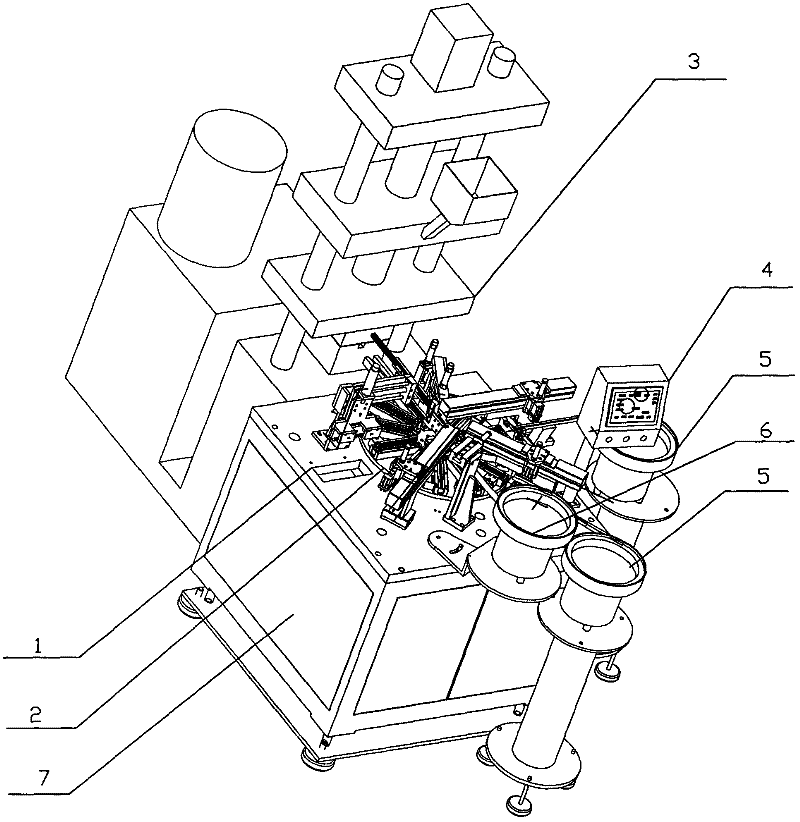

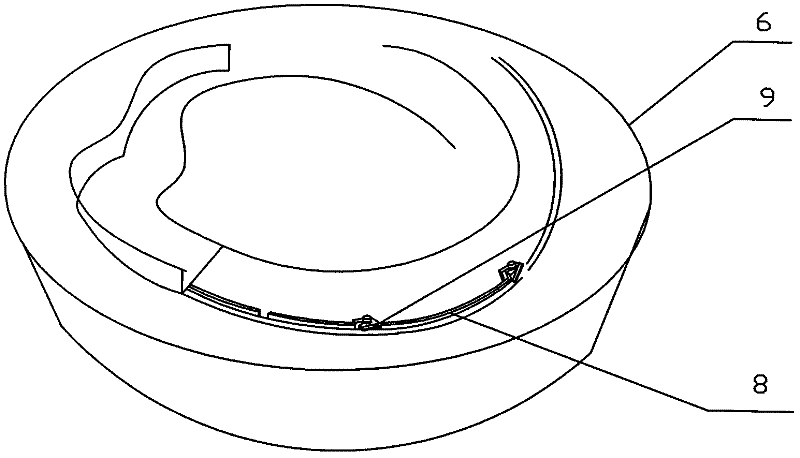

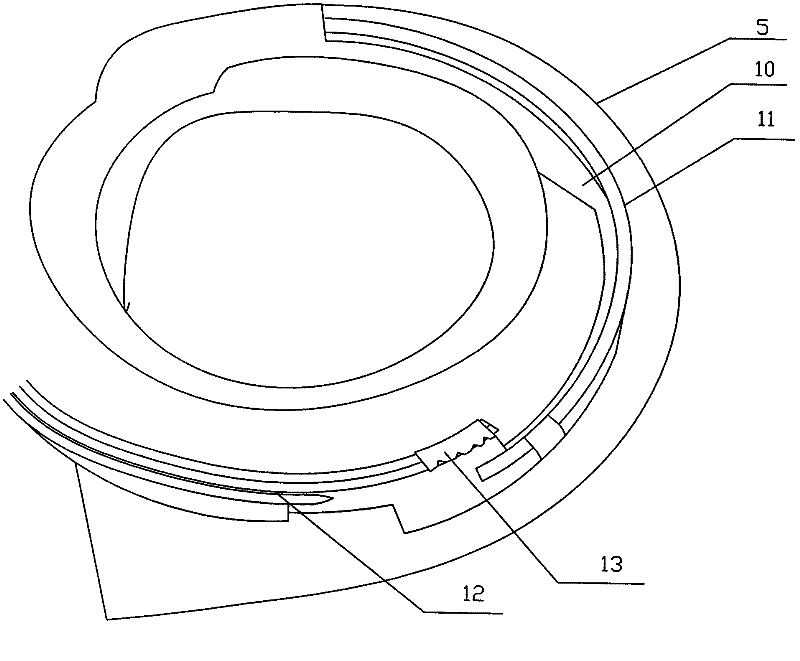

[0022] like figure 1 , 2 , 3 and 4, an RCA connector automatic assembly injection molding compound machine, including a base 7, the base is provided with a rotating disk 2, the rotating disk 2 is connected with a tightening mechanism, and each radial direction on the rotating disk is sequentially set There is a mold track 17, and a clamping mold 18 is embedded in the groove of the mold track 17. The surroundings of the rotating disk are respectively equipped with a needle feeding mechanism for loading copper core needles into the clamping mold, and a copper shell is installed in the clamping mold. The shell feeding mechanism, the positioning mechanism for positioning the copper shell, the injection molding mechanism for injecting the copper core needle and the copper shell on the clamping mold into connectors, the discharging mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com