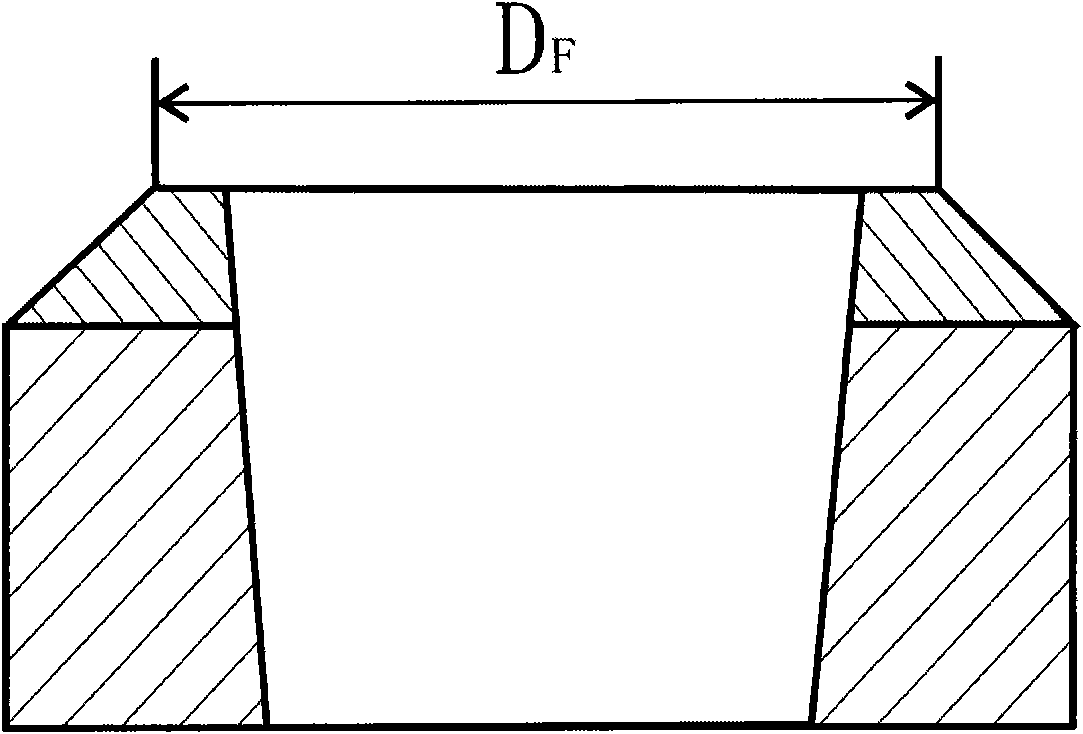

Chamfer diameter measurement method for oil drilling tool connector

A technology of diameter measurement and drill joint, which is applied in the direction of mechanical diameter measurement, etc., can solve the problems of inaccurate measurement and low measurement work efficiency, and achieve the effect of solving the inability to directly and accurately measure, ensuring measurement work, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

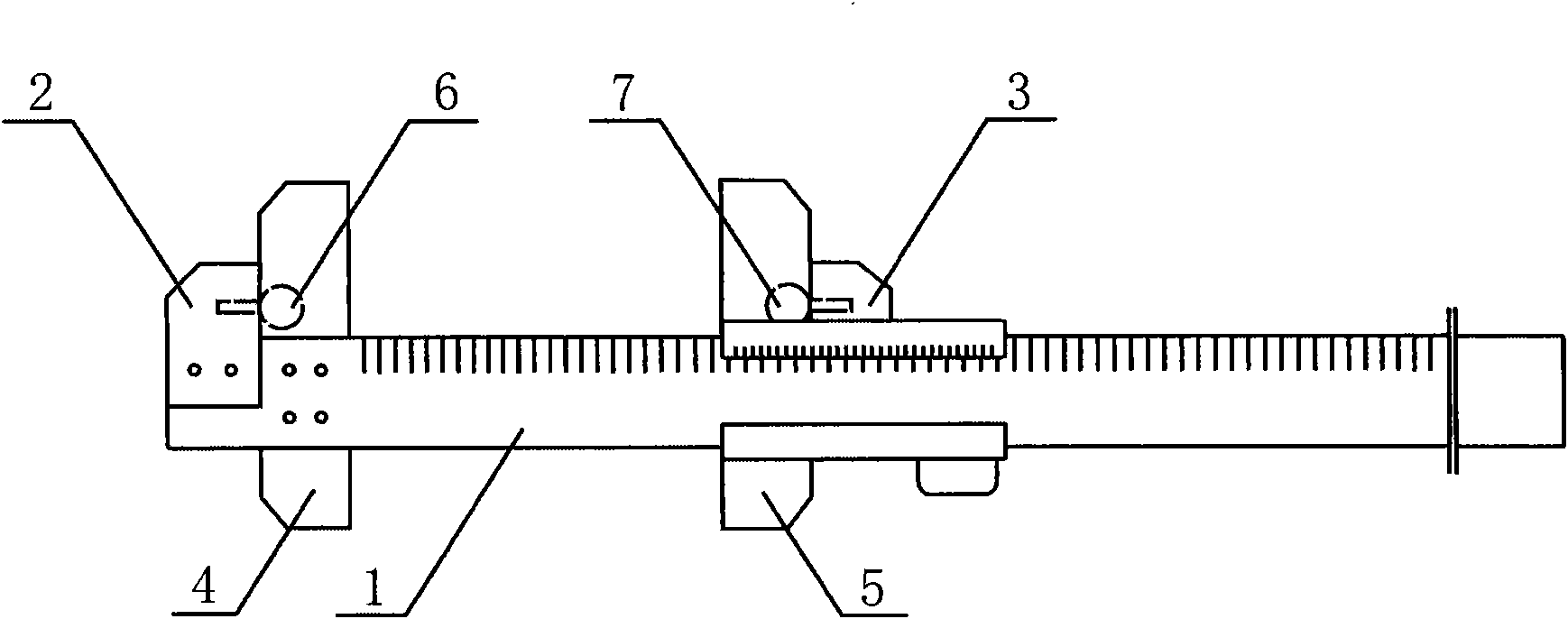

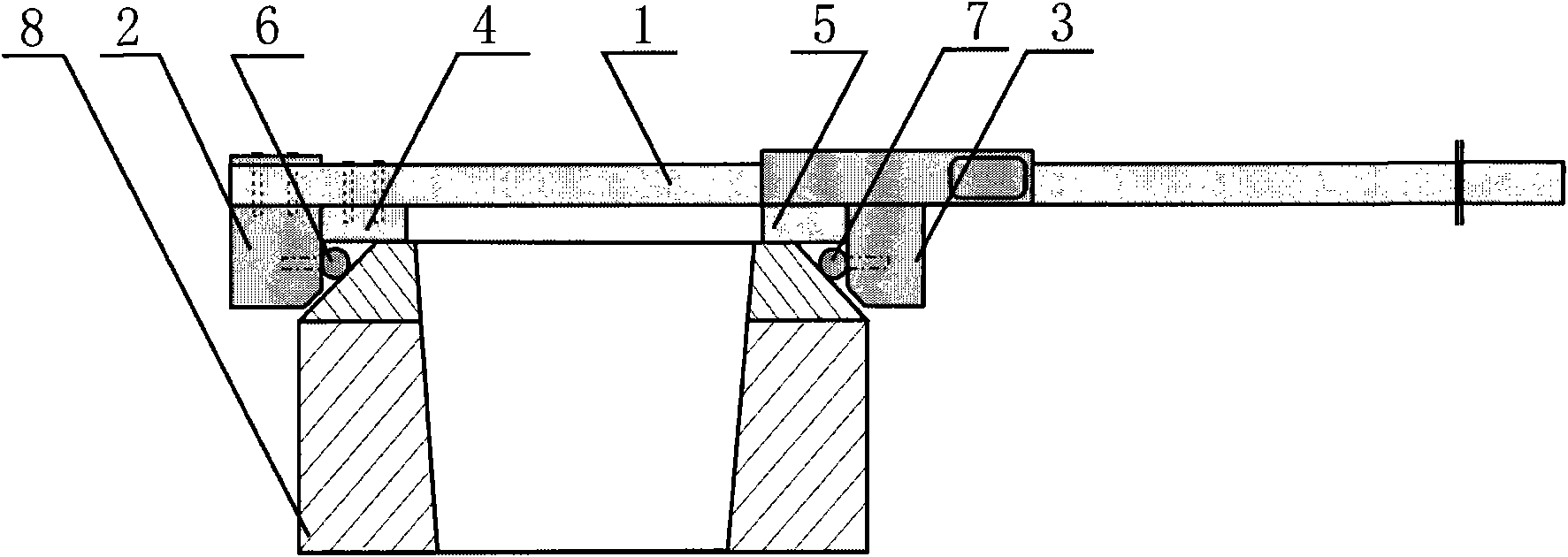

[0014] Drill tool joint chamfer diameter D according to the present invention F The measuring tool consists of the main measuring ruler 1, the fixed end measuring arm 2, the sliding end measuring arm 3, the fixed end measuring datum plane 4, the sliding end measuring datum plane 5, the fixed end steel spherical probe 6, and the sliding end steel spherical probe 7 constitutes; the fixed-end measurement reference plane 4 is fixed at the zero scale at the end of the main measuring ruler 1, the fixed-end measuring arm 2 is fixed on the top of the main measuring ruler 1, and the fixed-end steel spherical probe 6 is fixed on the fixed-end measuring arm 2, the sliding end measurement datum surface 5 and the sliding end measuring arm 3 are fixed on a slide rail, and the slide rail is placed on the scale end of the main measuring ruler 1, and can slide left and right on the scale end of the main measuring ruler 1.

[0015] refer to image 3. When measuring, put the fixed end measureme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com