Integrated concrete pile tip and manufacturing method thereof

A concrete pile, one-piece technology, applied in the direction of sheet pile walls, manufacturing tools, reinforcement molding, etc., can solve the problems of non-vertical pile body, inconvenient construction, breakage and fracture, etc., to reduce pile material damage, simple structure, and pile formation The effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

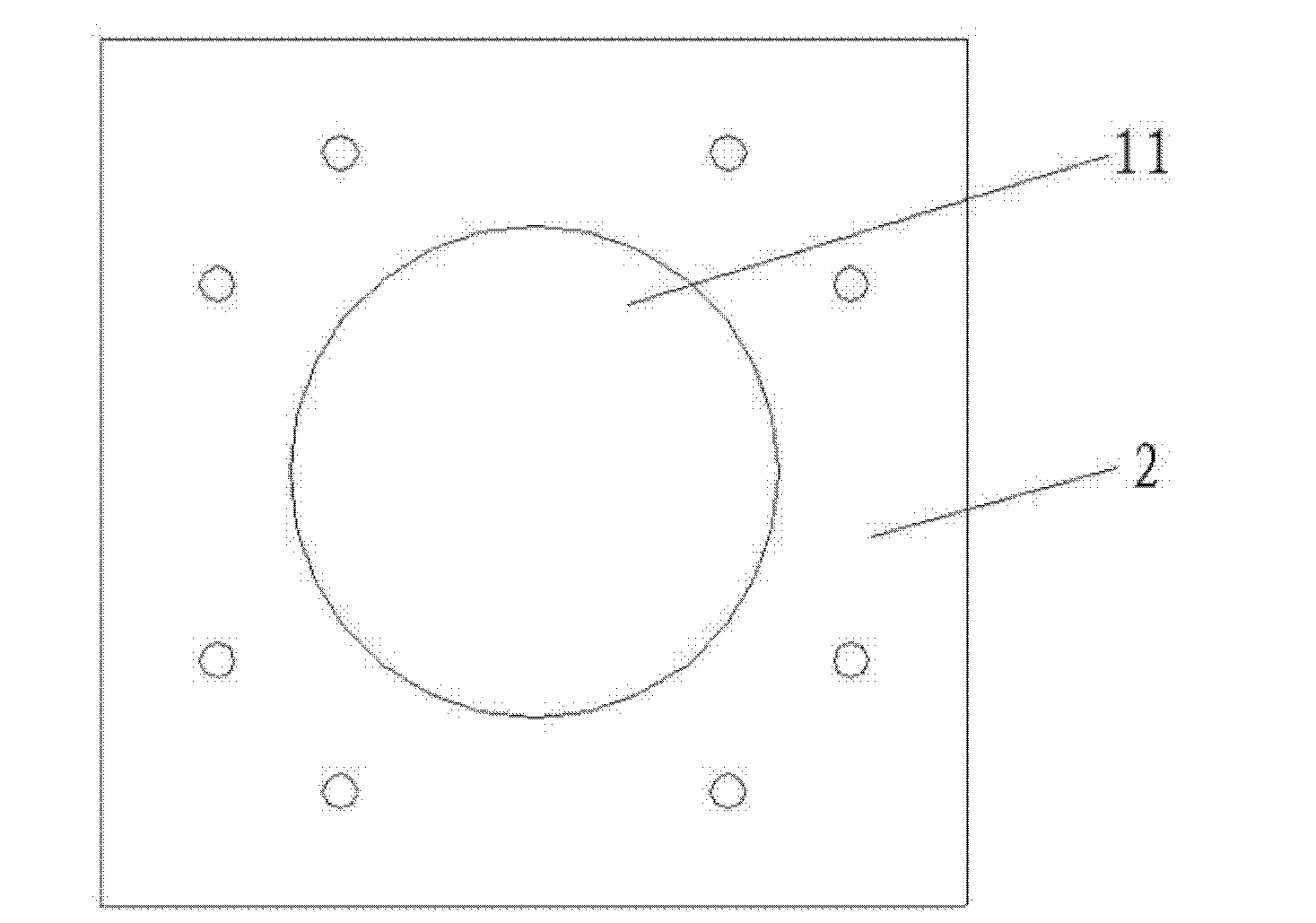

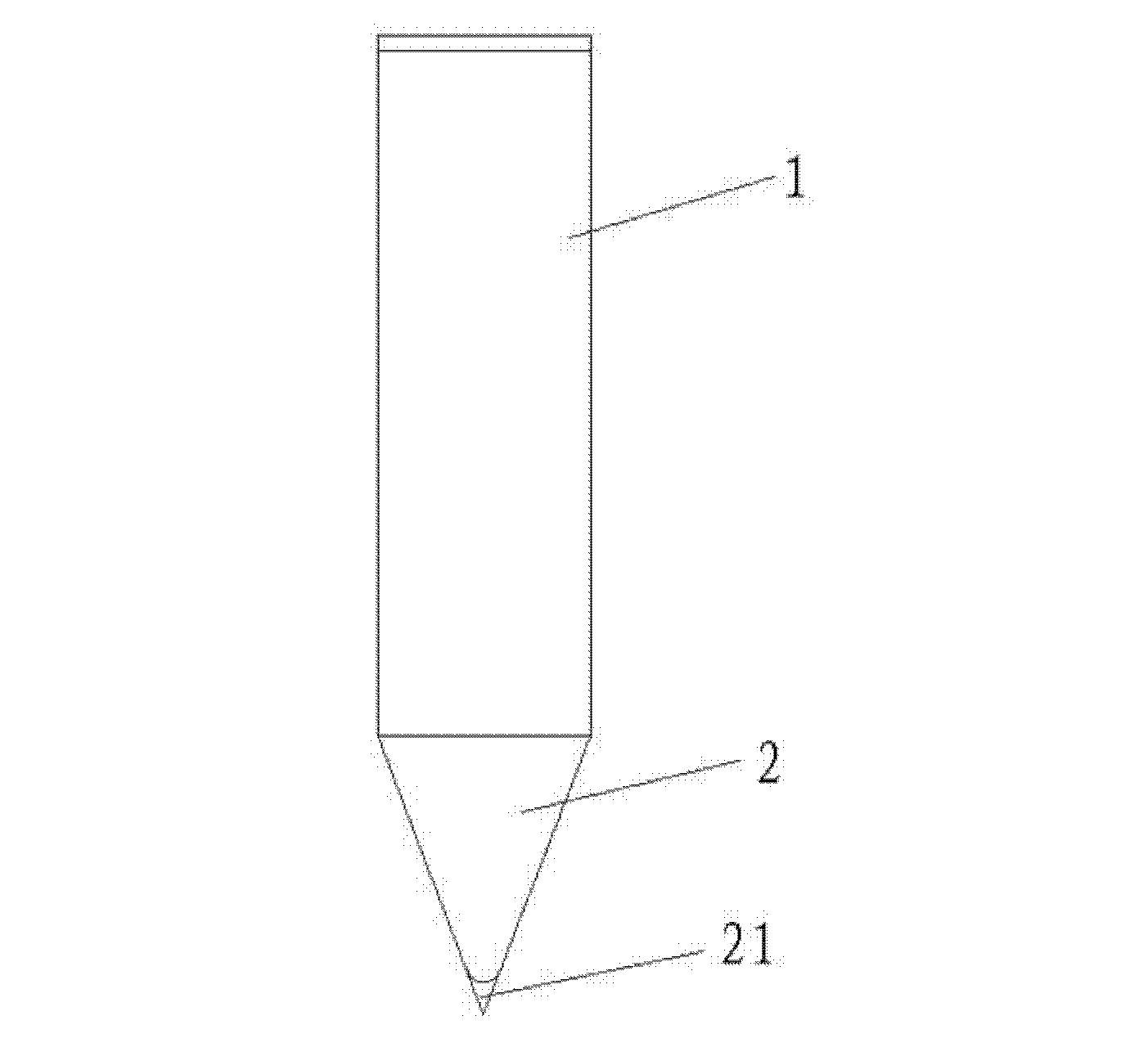

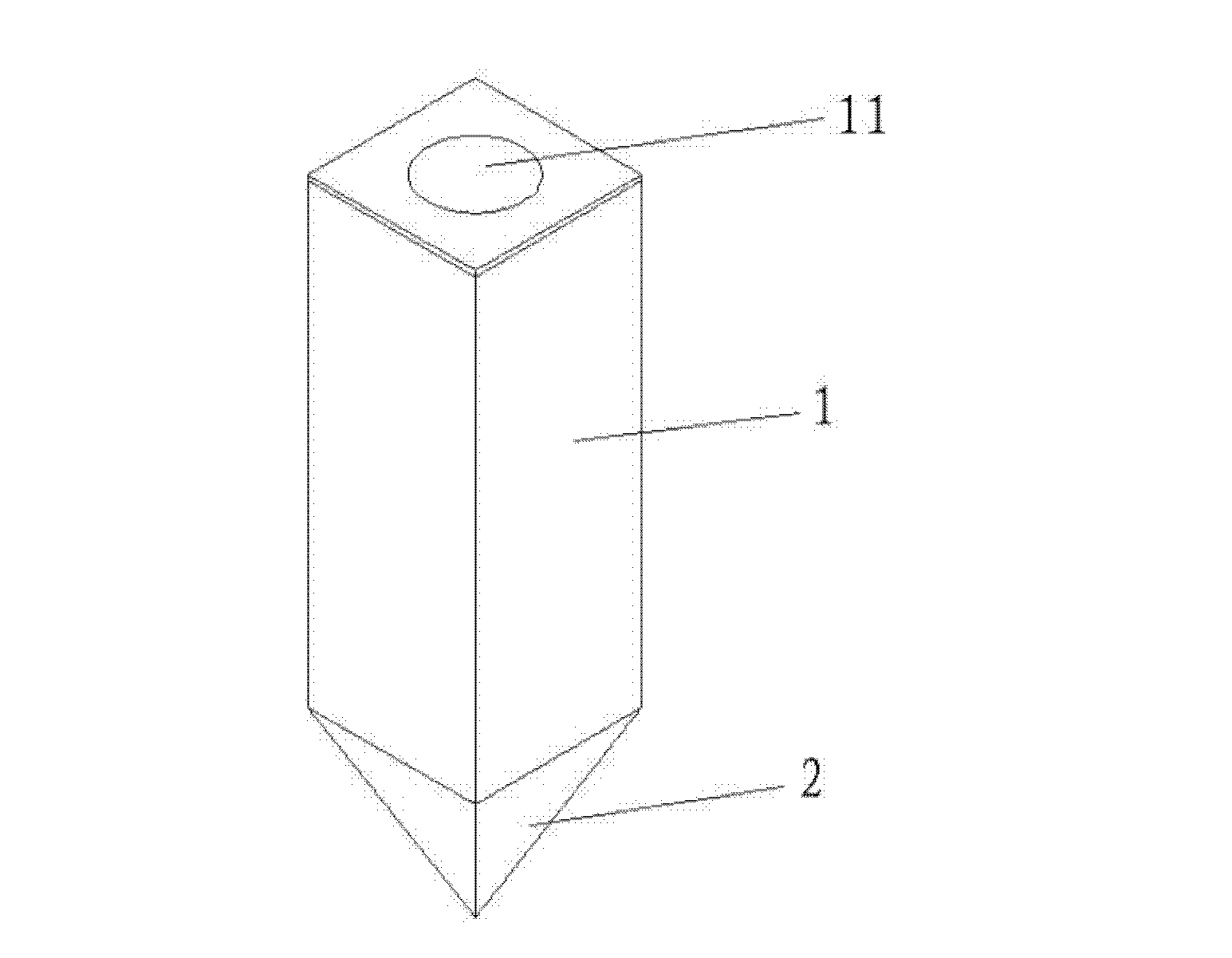

[0033] see figure 1 , figure 2 , image 3 ,

[0034] One-piece concrete pile point, the pile body part is a square pile 1, the square pile 1 is a hollow square pile, the inside of the square pile has a circular hole 11, and a steel square cone 21 is arranged at the front end of the pile point 2.

[0035] One-piece concrete pile points are divided into two types: integral type and assembly type. The integral type one-piece concrete pile point can be produced by centrifugal molding of the pile point and the pile body; the assembly type one-piece concrete pile point is prepared first. Then it is made after being connected with the pile body as a whole.

[0036] The prestressed steel bars run through the axial direction of the integral concrete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com