Tobacco shred box sealing machine

A technology of box sealing machine and smoke box, which is applied in packaging sealing/tightening, automatic packaging control, external support, etc., can solve the problems of high labor intensity, low work efficiency, and fully automatic operation of difficult silk-making logistics system, and achieves Reasonable layout, compact structure and accurate action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the content of the present invention is not limited thereto.

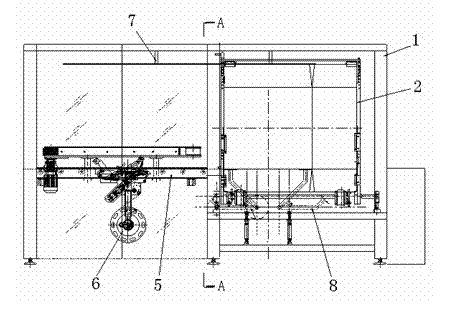

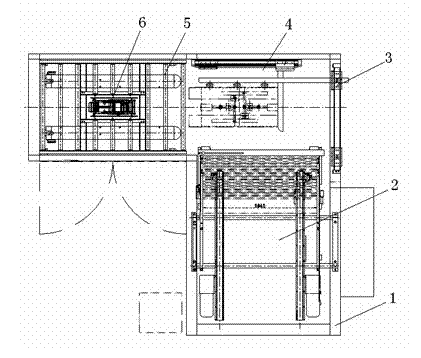

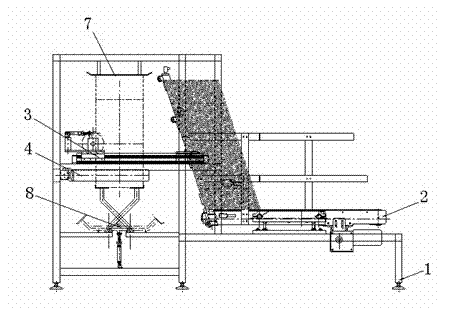

[0031] The shredded tobacco box sealing machine provided by the present invention comprises a frame 1, on which a cigarette box storehouse 2, a cigarette box opening mechanism 3, a box folding mechanism 8, a box delivery mechanism 4,5 and a box sealing mechanism 6 are arranged, such as figure 1 , figure 2 , image 3 ,in:

[0032] The cigarette box storehouse 2 includes an adjuster 21 arranged on the frame 1, two parallel conveyors 22 and their power drivers 24 arranged on the adjuster 21, so that when the smoke box is sent into the smoke box storehouse 2, it is adjusted by the adjuster 21 The height of the smoke box warehouse 2 is to adjust the height of the smoke box warehouse 2 through the nut and the screw rod 25 on the regulator 21. The regulator 21 is also provided with a smoke box guardrail 23 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com