Side-bend energy absorbing buffer stem

A technology of bow and buffer section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

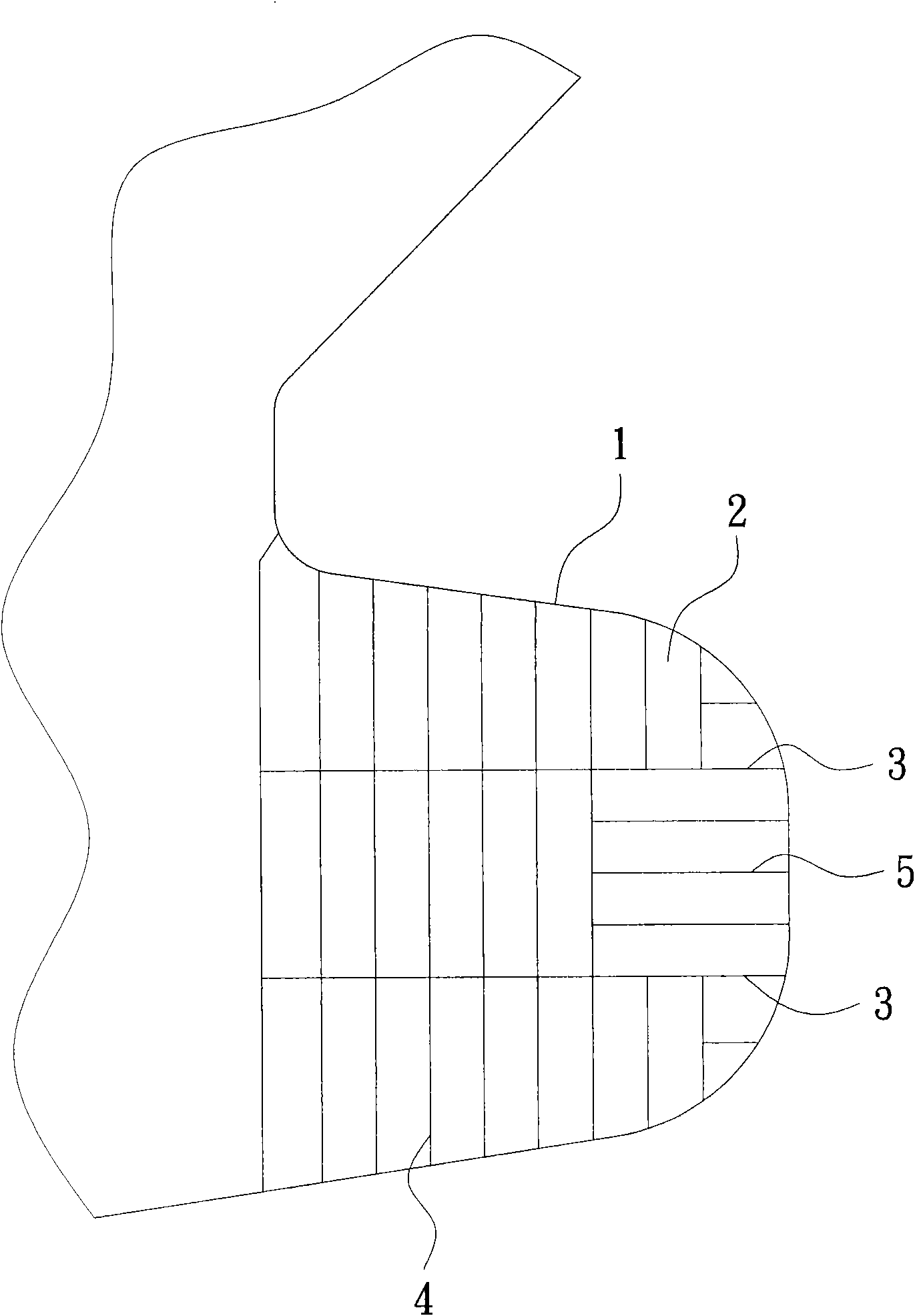

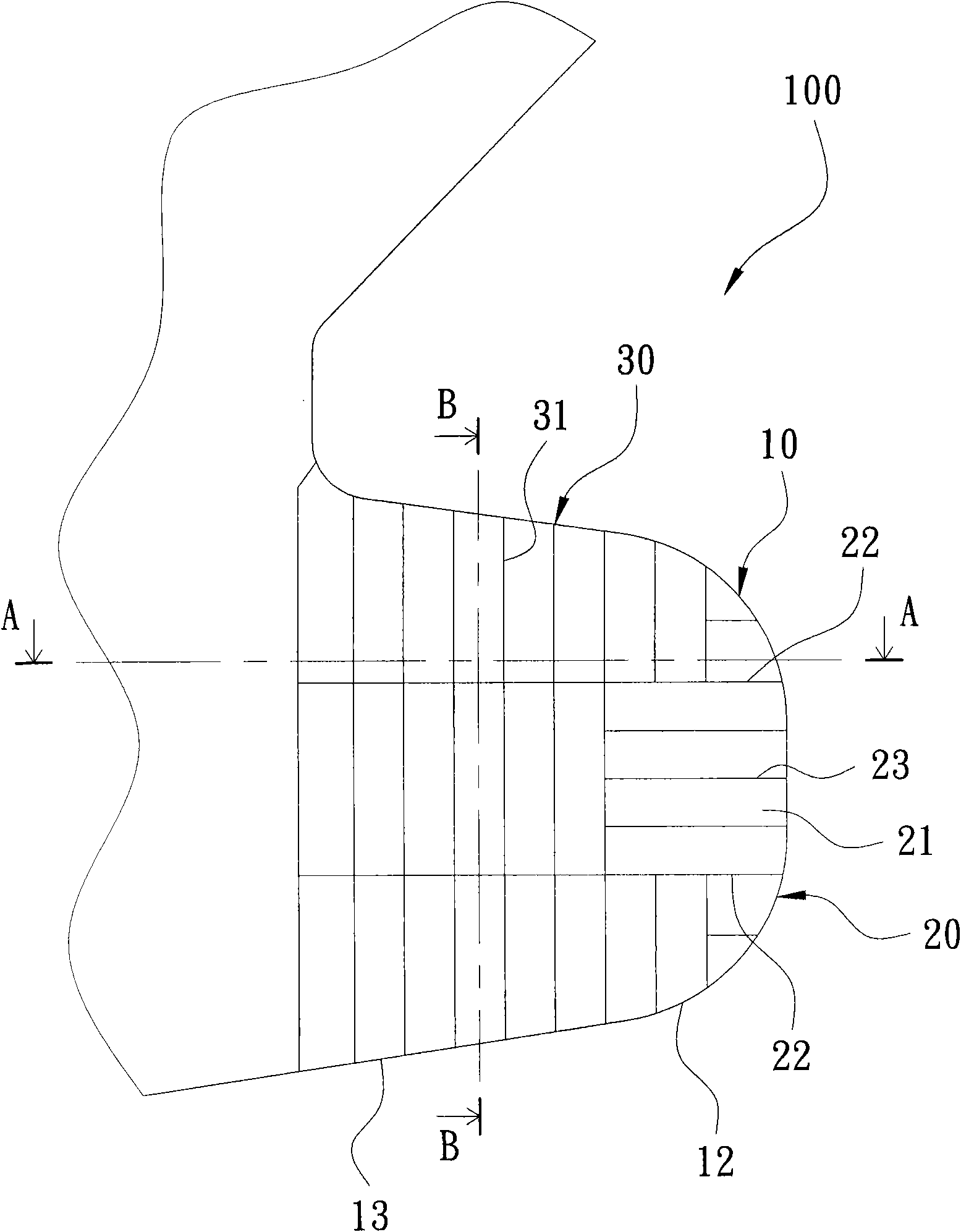

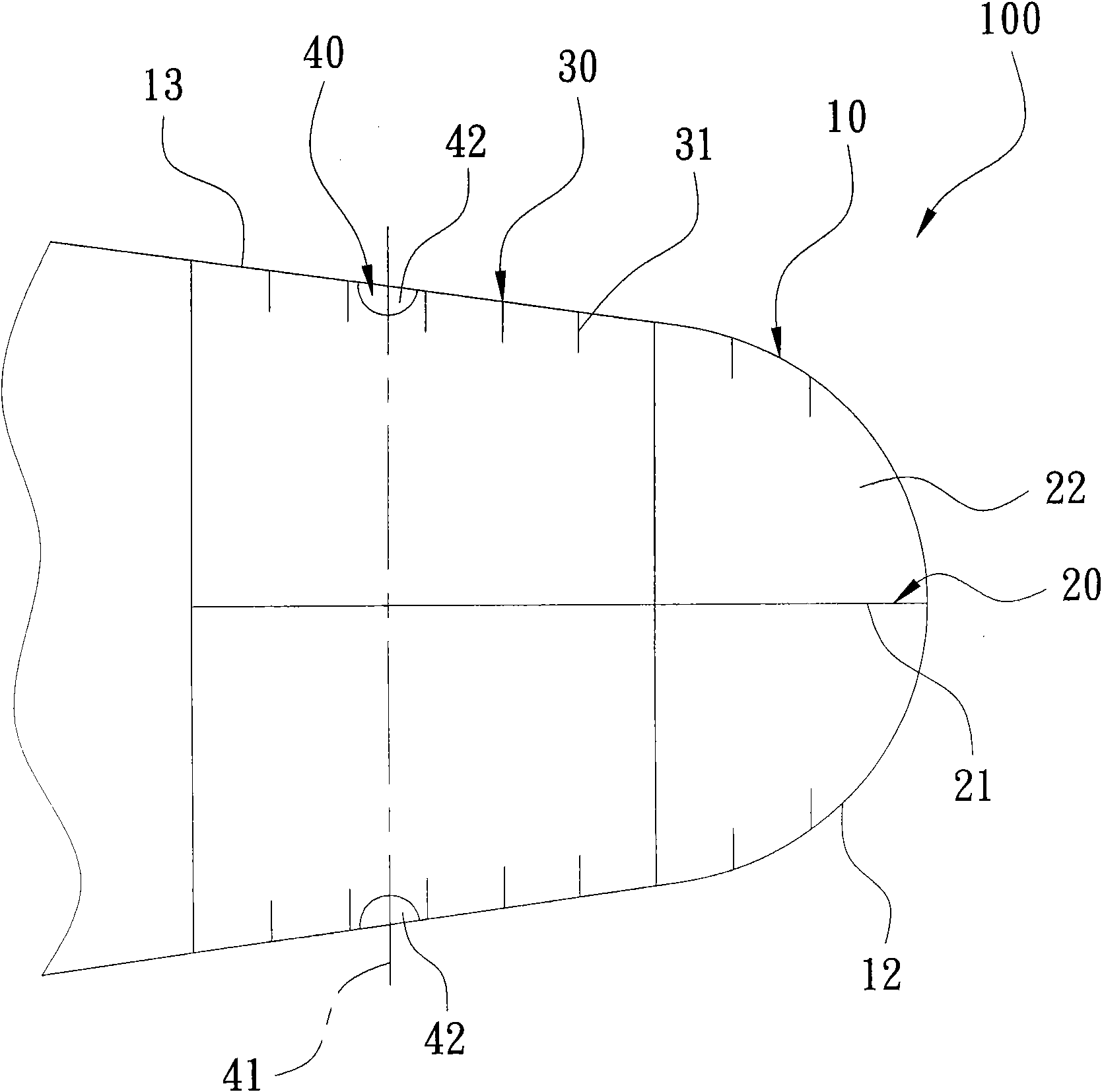

[0017] see figure 2 , image 3 as well as Figure 4 Shown is a schematic side view of the internal structure of a preferred embodiment of the present invention, along figure 2 The top view of the internal structure of the section line A-A and the schematic diagram along the figure 2 The cross-sectional view of the B-B front view section line in the figure discloses a side-curving and collapsible cushioning bow 100, which mainly includes:

[0018] A ship hull 10 is provided with a chamber 11 therein, and the ship hull 10 can be divided into a sternal rib section 12 at the front end and a buffer section 13 behind the sternal rib section 12 .

[0019] A longitudinal structural unit 20, which is accommodated in the chamber 11, and has a centerline stringer 21 arranged vertically, and two horizontal stringers 22 arranged horizontally, and several And the sternum ribs 23 are horizontally stacked.

[0020] A transverse structural unit 30 is accommodated in the chamber 11 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com