Air source device

A technology of air source and main air duct, which is applied in the direction of grinding drive devices, grinding machine parts, metal processing equipment, etc., and can solve the problem that a single pipeline cannot meet the continuous air supply and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

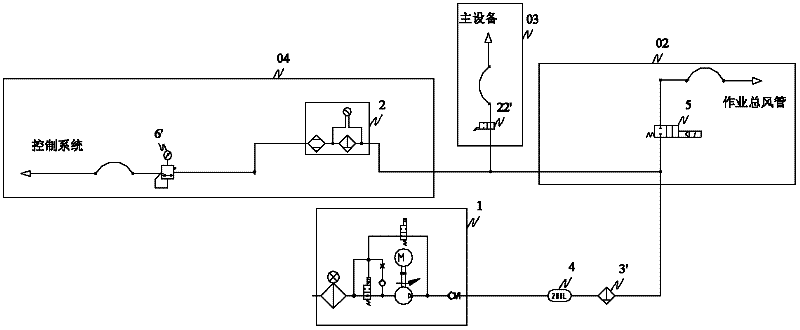

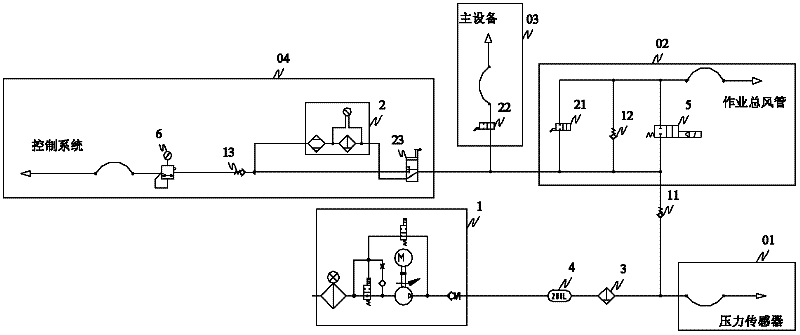

[0029] The invention provides a wind source device, such as figure 2 As shown, the air source device includes an air compressor 1, an air storage tank 4, a dryer 2, and a first filter 3. The air outlet of the air compressor 1 is connected to the air inlet of the air storage tank 4 through a pipeline, and the air storage tank 4 is output The gas port is connected to the air inlet of the first filter 3 through a pipeline, and the gas outlet of the first filter 3 is divided into a detection branch 01 and a gas supply main circuit, wherein the detection branch 01 provides a pressure detection interface for connecting a pressure sensor, and the gas supply The main road is equipped with a first one-way valve 11, and the air outlet of the first one-way valve 11 is respectively connected to the air supply branch 02 of the operation main air pipe, the air supply branch 03 of the main equipment and the air supply branch 04 of the control system; The gas supply branch 02 is composed of ...

Embodiment 2

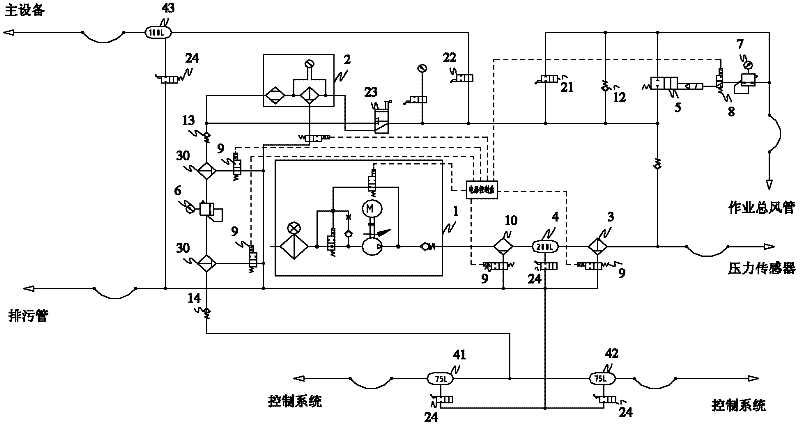

[0032] As a further improvement of the above embodiment, as image 3 As shown, on the basis of Embodiment 1, the wind source device of this embodiment also includes a first auxiliary air storage tank 41, a second auxiliary air storage tank 42 and a fourth one-way valve 14; wherein, the first auxiliary air storage tank The air inlet of the tank 41 and the air inlet of the second auxiliary air storage tank 42 are respectively connected to the air outlet of the fourth check valve 14, the air outlet of the first auxiliary air storage tank 41 and the outlet of the second auxiliary air storage tank 42. The air port is used to connect the air inlet of the control system respectively; the air inlet of the fourth one-way valve 14 is connected with the air outlet of the first decompression valve 6, and the air outlet of the fourth one-way valve 6 is respectively connected with the first auxiliary gas storage tank 41 and the first auxiliary air tank 41 Two auxiliary gas tanks 42.

[003...

Embodiment 3

[0037] Such as image 3 As shown, on the basis of the first or second embodiment above, the wind source device of this embodiment also includes a gas-water separator 10 for purifying the gas from the air compressor, and the gas-water separator 10 is further The air port is connected to the air outlet of the air compressor 1, and the air outlet of the gas-water separator 10 is connected to the air inlet of the air storage tank 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com