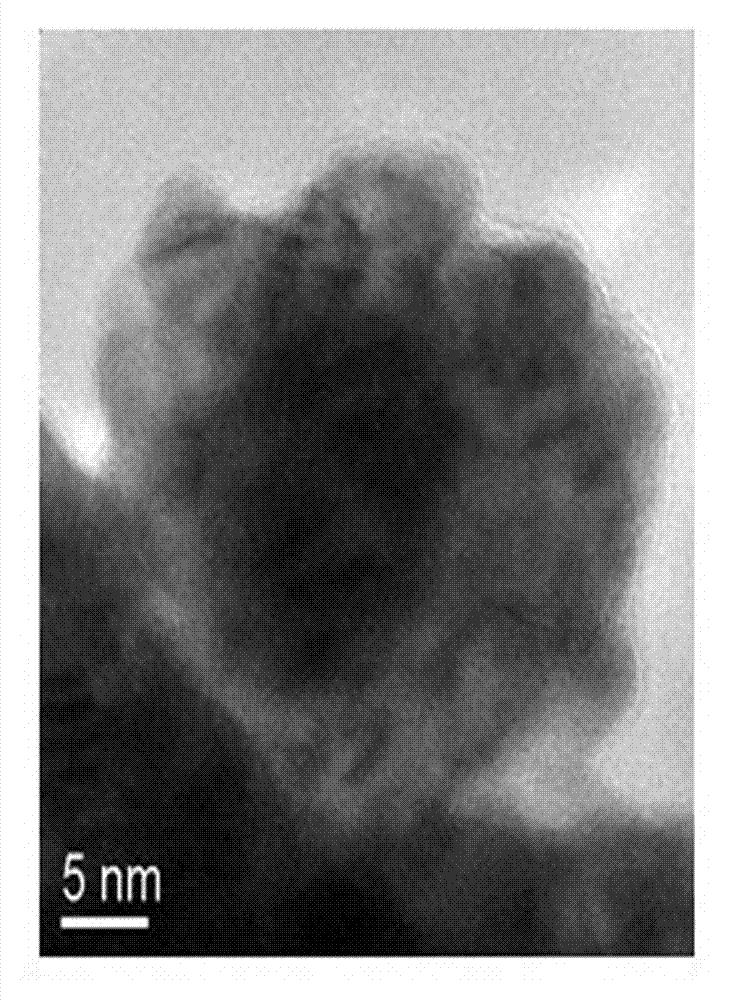

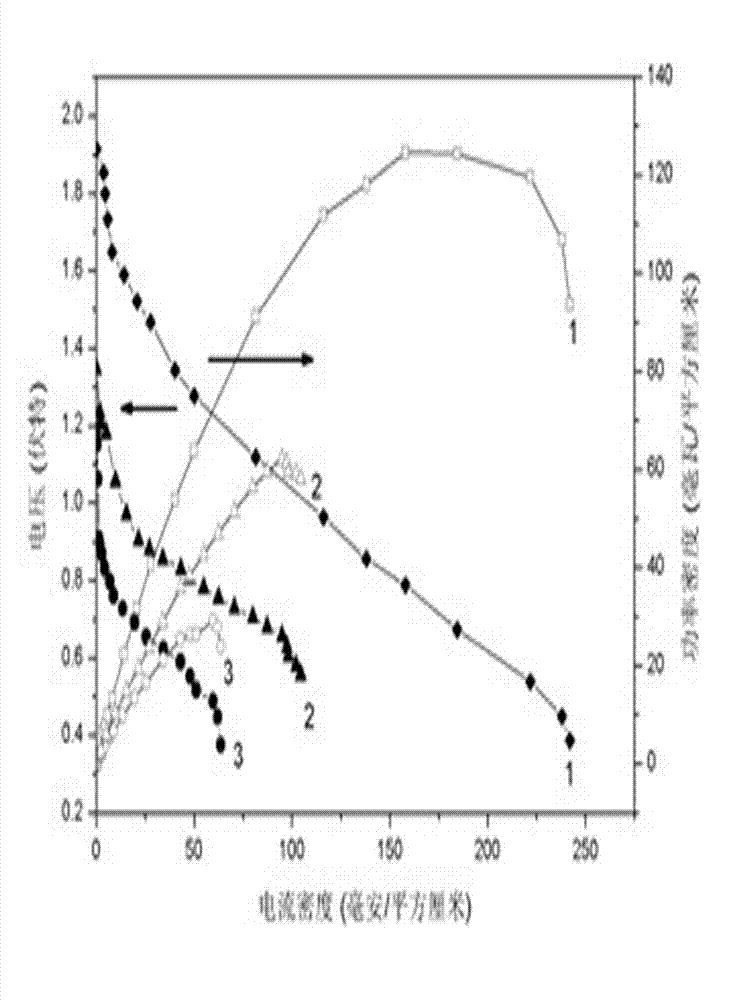

Core-shell structural anode catalyst for direct borohydride fuel cells and preparation method thereof

A core-shell structure, borohydride technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, battery electrodes, etc., can solve the problem of low anode activity, serious hydrogen desorption from water, fuel utilization It can improve the utilization rate, high activity and less hydrogen evolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of Cu nanoparticles: Cu(NO 3 )·3H 2 O and polyvinylpyrrolidone (PVP) were sequentially added to 20 ml of ethylene glycol, so that the concentration of Cu atoms in ethylene glycol was 20 mmol / L, and polyvinylpyrrolidone (PVP) in ethylene glycol The concentration is 3 g / L. Stir and pass nitrogen gas for 25 minutes to make it fully mixed, then heat to 60°C, continue to pass nitrogen gas and stir continuously, and the dropwise concentration is 0.3 mol L -1 Hydrazine hydrate solution, the molar amount of hydrazine hydrate added is twice that of Cu element, and the dropping rate is 40 drops·min -1 , reacted for 40 min to prepare Cu nano catalyst sol, then suction filtered and washed with distilled water to obtain Cu nanoparticles;

[0033] (2) Re-dissolve the Cu nanoparticles in the above (1) in 20 ml of ethylene glycol, add polyvinylpyrrolidone (PVP) under stirring to make the concentration 3 g / L, blow in nitrogen and stir For 30 minutes, add a tetrahydro...

Embodiment 2

[0036] (1) Preparation of Ni nanoparticles: NiCl 2 ·6H 2 O and tetraoctylammonium bromide were added to 20ml of water in turn, so that the concentration of Ni atoms in the water was 10 mmol / L, and the concentration of tetraoctylammonium bromide in water was 1.5 g / L. Stir and pass nitrogen gas for 20 minutes to make it fully mixed, then heat to 50°C, continue to pass nitrogen gas and stir constantly, the dropwise concentration is 0.3 mol L -1 Lithium triethyl borohydride solution, adding lithium triethyl borohydride molar weight is 1.5 times that of Ni element, and the dropping speed is 40 drops min -1 , and reacted for 40 min to prepare Ni nano catalyst sol, then suction filter and wash with distilled water to obtain Ni nanoparticles;

[0037] (2) Re-dissolve the M nanoparticles in the above (1) in 20 ml of water, add tetraoctyl ammonium bromide under stirring, the concentration of tetraoctyl ammonium bromide is 1.5g / L, blow in nitrogen and stir for 30 Minutes, then add a t...

Embodiment 3

[0040] (1) Preparation of Pt nanoparticles: H 2 PtCl 6 ·6H 2 O and polyethylene glycol were sequentially added to 20 ml of tetrahydrofuran, so that the concentration of Pt atoms in tetrahydrofuran was 30 mmol / L, and the concentration of polyethylene glycol in tetrahydrofuran was 5 g / L. Stir and pass nitrogen gas for 30 minutes to make it fully mixed, then heat to 80°C, continue to pass nitrogen gas and stir constantly, the dropwise concentration is 0.3 mol L -1 Sodium borohydride solution, the molar weight of sodium borohydride added is 2.5 times that of Pt element, and the dropping rate is 40 drops·min -1 , reacted for 60 min, prepared Pt nano catalyst sol, then suction filtered, and washed with distilled water to obtain Pt nanoparticles;

[0041] (2) Redissolve the Pt nanoparticles in the above (1) in 20ml tetrahydrofuran, add polyethylene glycol under stirring, the concentration of polyethylene glycol is 5g / L, blow in nitrogen and stir for 30 minutes, and then follow the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com