Wall-mounted high-current socket

A high-current, wall-mounted technology, used in circuits, electrical components, coupling devices, etc., can solve problems such as damage, copper foil aging and peeling, fire, etc., and achieve the effects of reliable operation, compact structure and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

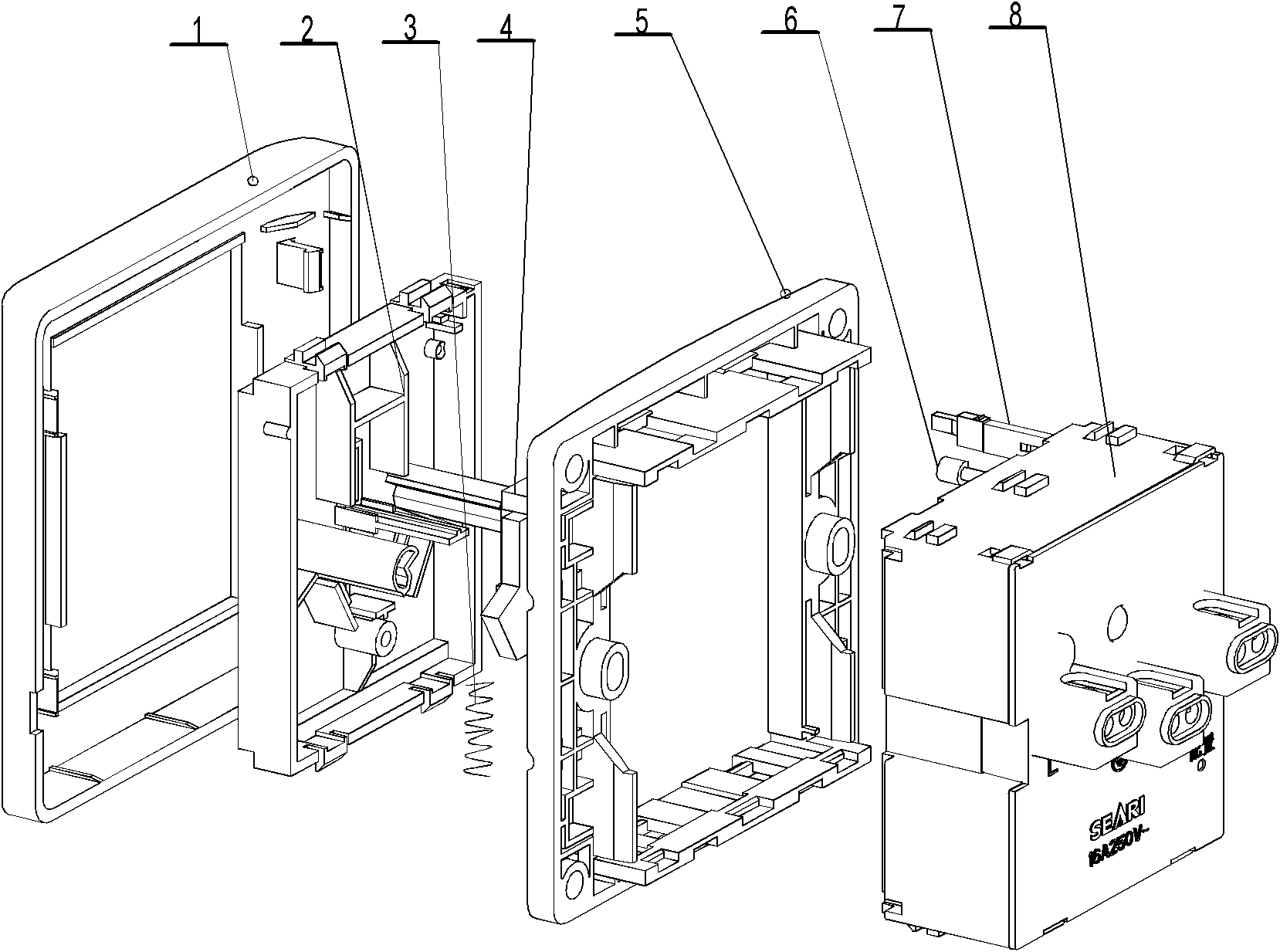

[0011] The embodiment of the present invention is further described below in conjunction with the accompanying drawings: the present invention is made up of shell cover 1, face shell 2, compression spring 3, protective door 4, light guide column 5, reset lever 6, frame 7, control submodule 8, see figure 1 . Among them, the frame 7 is a hollow structure with mounting ribs, and the face shell 2 is assembled on the front side of the frame 7 through buckles, and then the protective door 4 and the compression spring 3 are sequentially installed, see figure 1 .

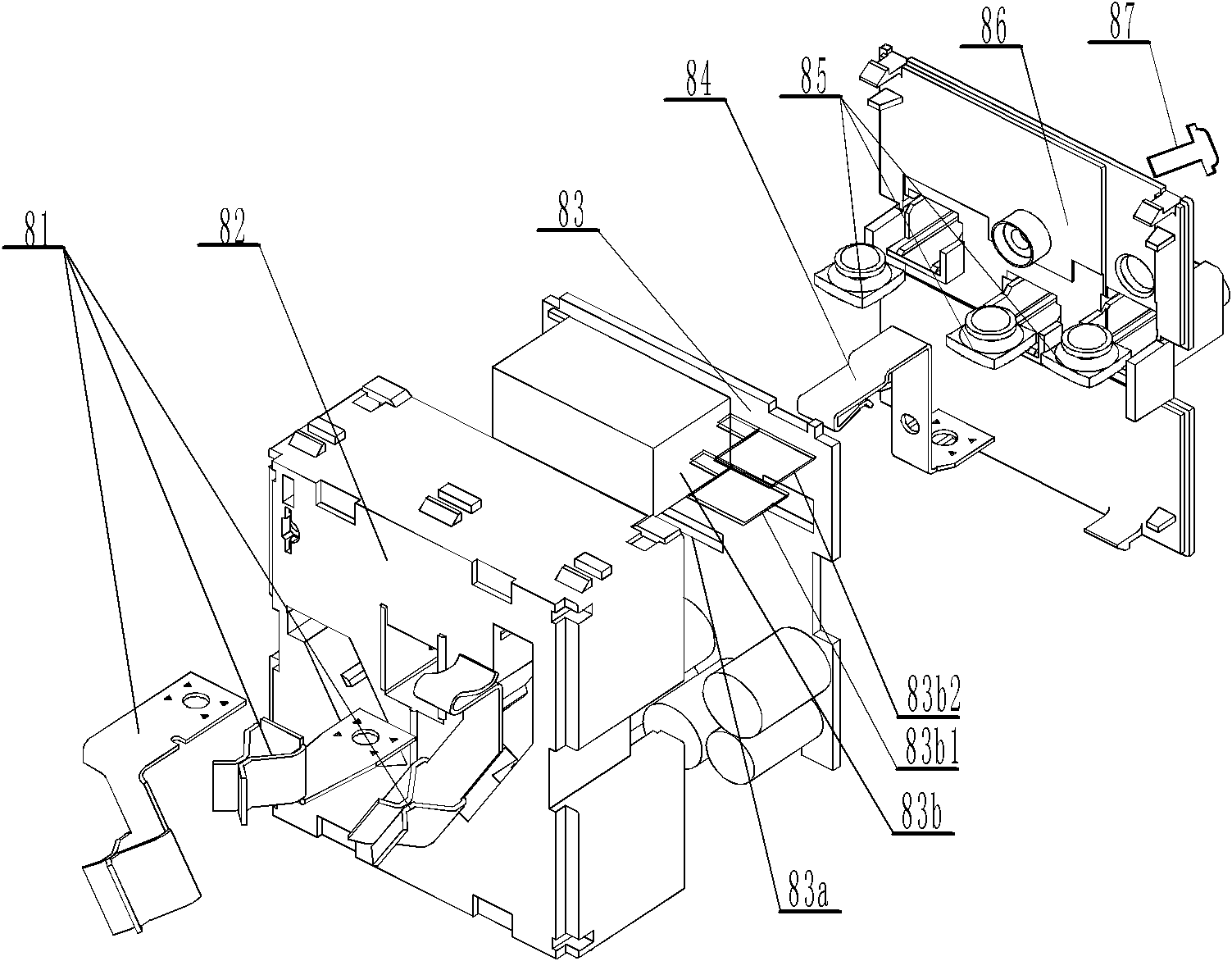

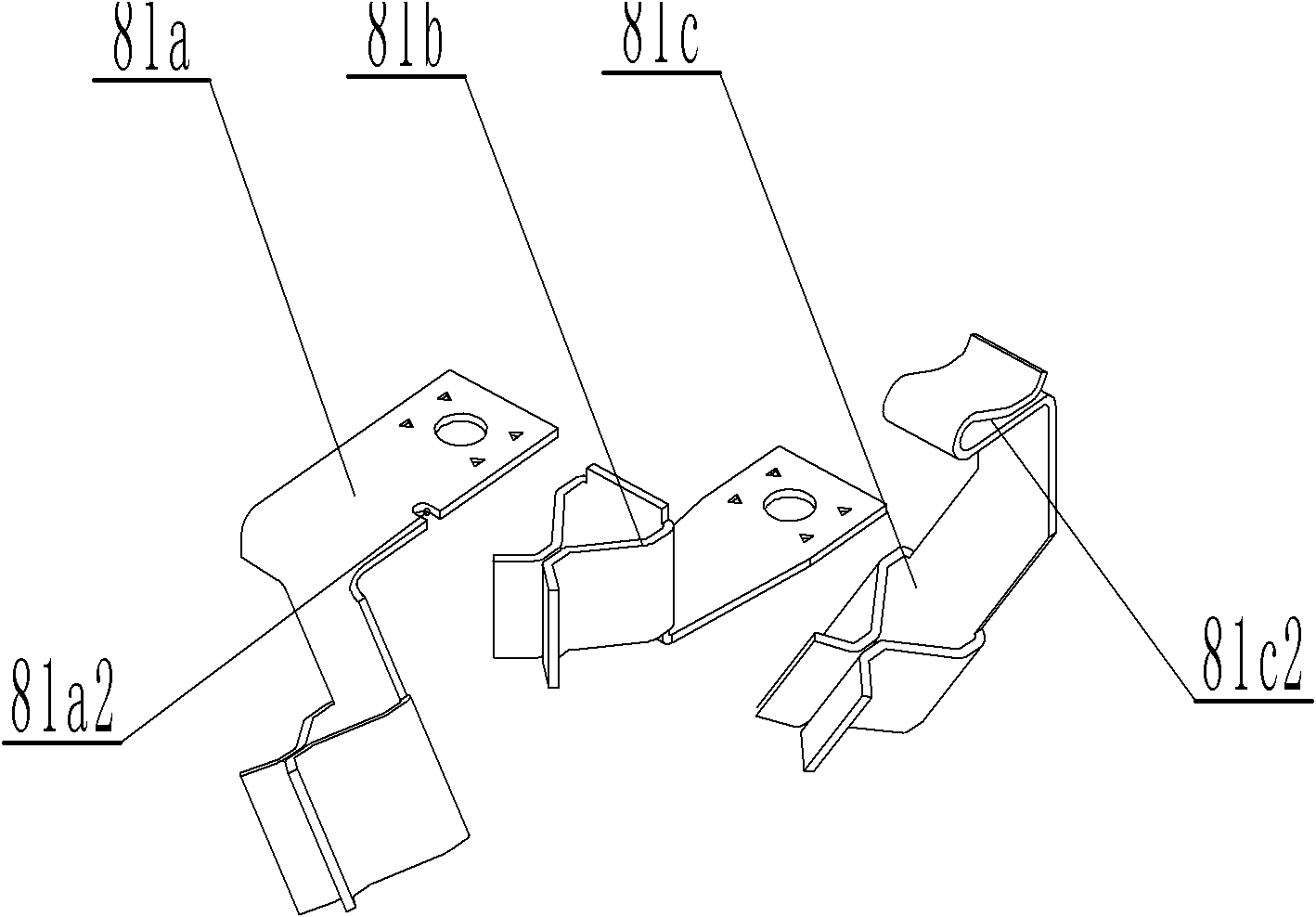

[0012] The control sub-module 8 includes a socket 81 (including three poles of L, N, and E), a housing 82, a control circuit board 83, a connecting plate 84, a crimping terminal 85, a rear cover plate 86, and fastening screws 87. Among them, the N pole socket 81a, the E pole socket 81b, and the L pole socket 81c are a separate part, and the user plug ends of the three sockets are all clamping structures, and the N pole soc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com