Display device and manufacturing method thereof

A technology of display device and structure, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as color mixing of displayed images, achieve good display performance, avoid transfer, and achieve high numerical aperture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, embodiments of the present invention (hereinafter simply referred to as embodiments) will be described in detail with reference to the accompanying drawings.

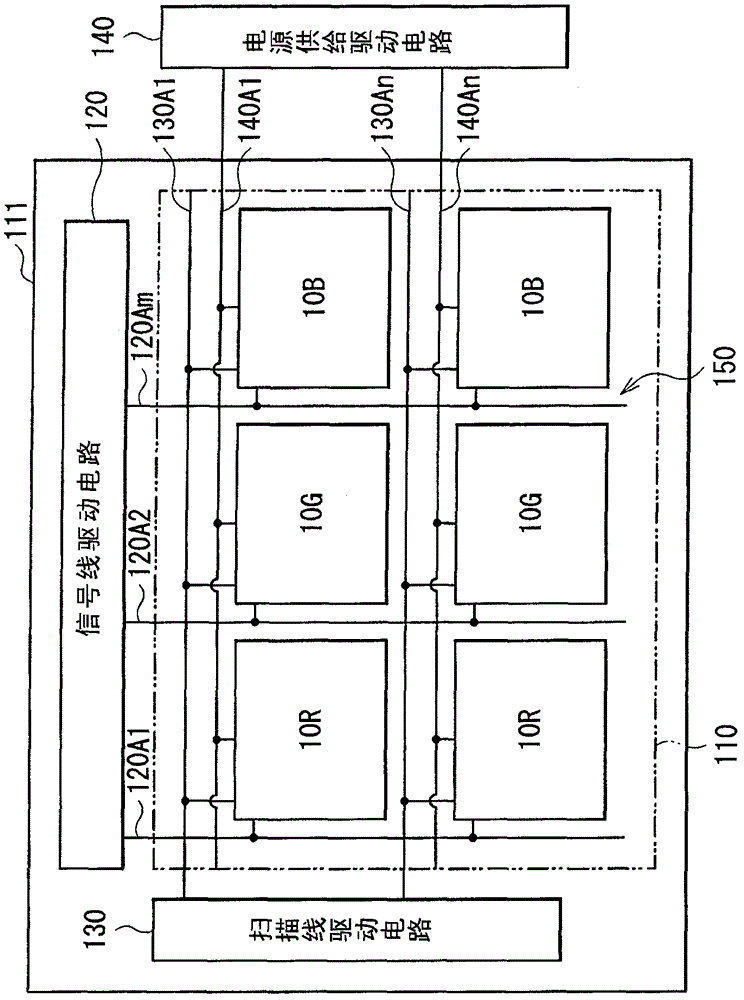

[0038] figure 1The configuration of a display device using an organic light emitting element according to an embodiment of the present invention is shown. The display device is used as an ultra-thin organic light-emitting color display device and the like. In this display device, a display region 110 is formed on a substrate 111 . Around the display region 110 on the substrate 111, for example, a signal line driver circuit 120 (which is a driver for image display), a scan line driver circuit 130, and a power supply line driver circuit 140 are formed.

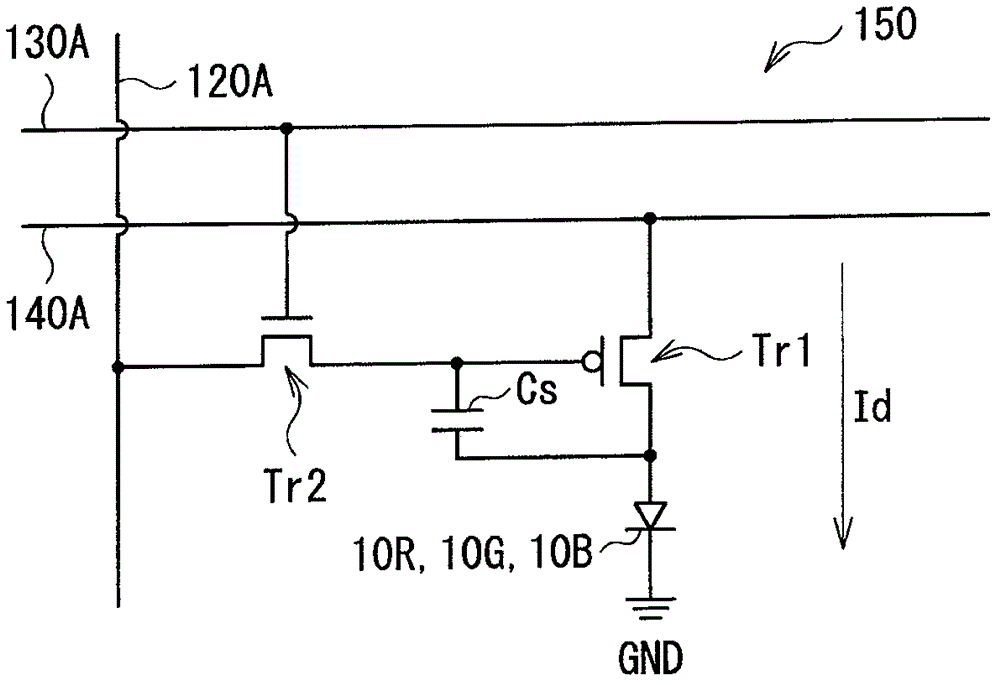

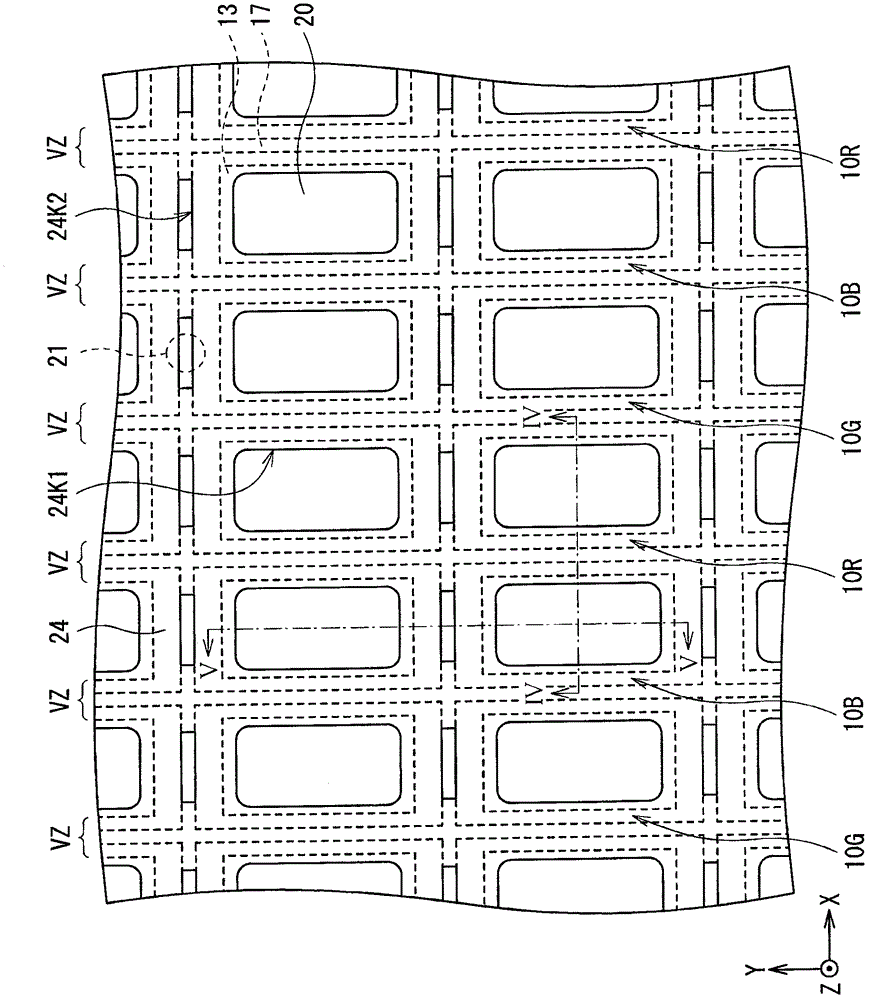

[0039] In the display area 110, a plurality of organic light emitting elements 10 (10R, 10G, and 10B) arranged two-dimensionally in a matrix, and a pixel driving circuit 150 for driving these organic light emitting elements are formed. In the pixel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com