Household straw gasification furnace

A gasifier and straw technology, which is applied in the field of household straw gasifier, can solve the problems of environmental pollution, loss, unstable use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

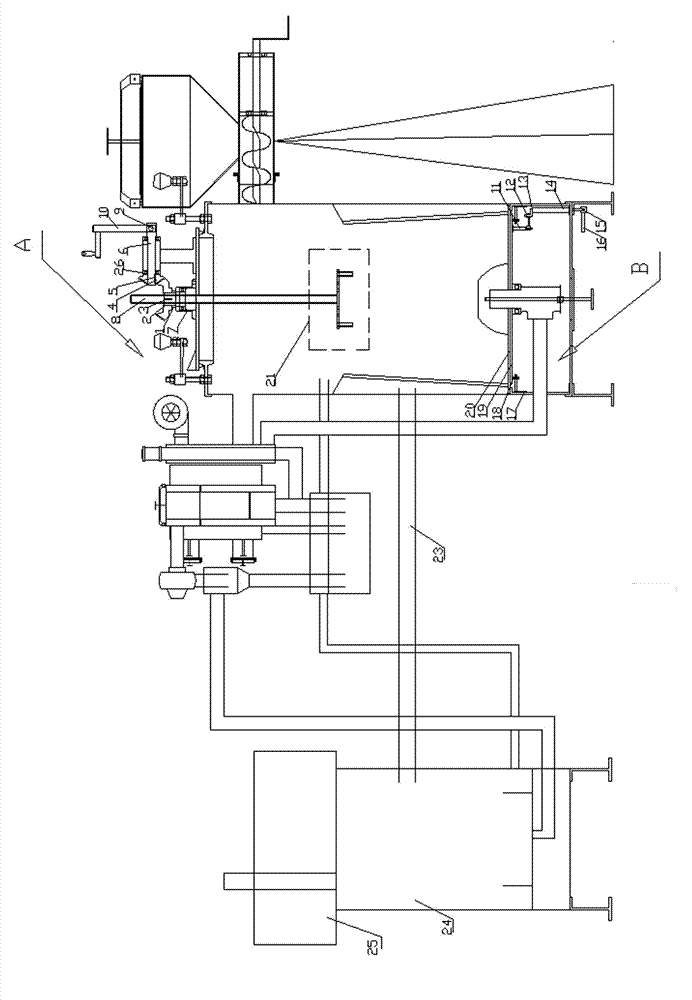

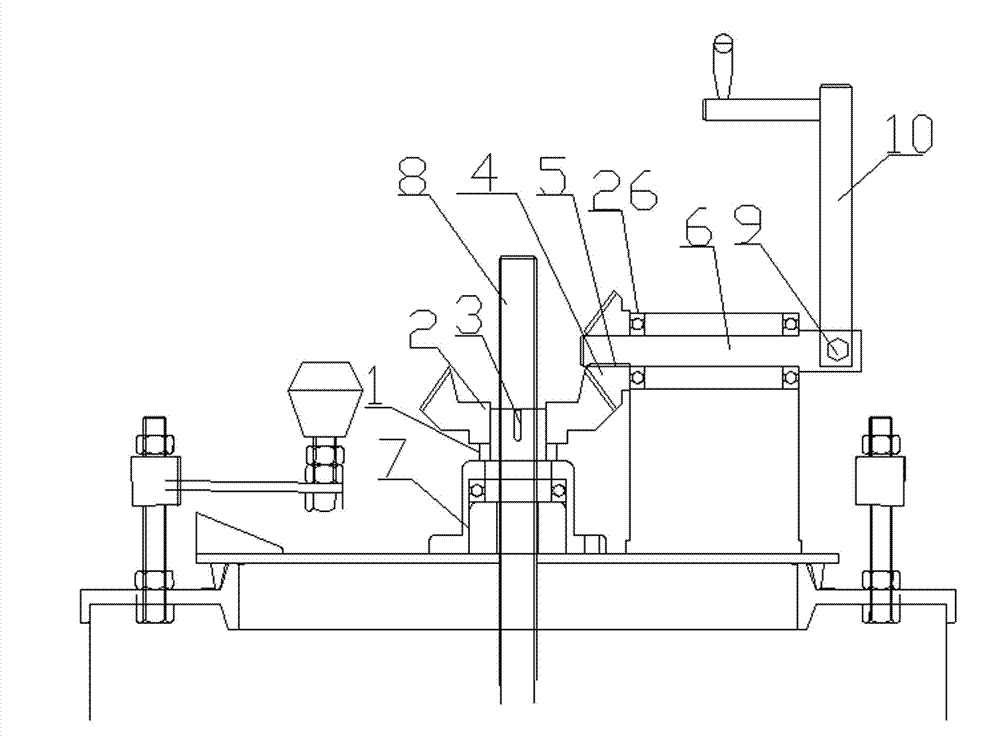

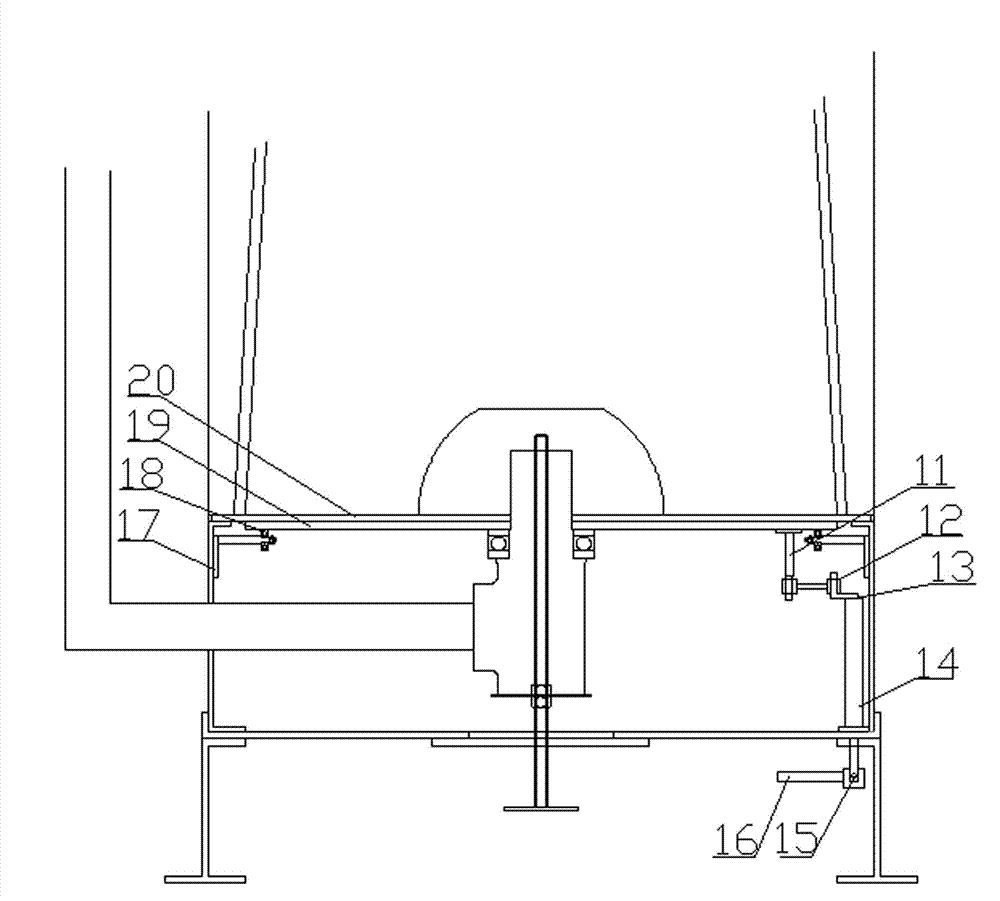

[0015] The present invention and its beneficial effects will be further described below in conjunction with the accompanying drawings.

[0016] refer to figure 1 , figure 2 , a household type straw gasification furnace, including a pressurization device and a flange 7 for fixing a pressurization screw 8 therein, a dust removal and coke removal device and large and small furnace teeth 20, 19 therein, and water circulation heating device, the structure of the pressurizing device is: the sleeve 1 is placed between the first bevel gear 2 and the flange 7, and the upper end of the first bevel gear 2 and the pressure screw 8 is fixedly connected by a key 3 , the second bevel gear 4 and one end of the rocker shaft 6 are fixedly connected by a key 5, and the first and second bevel gears 2 and 4 mesh with each other; the rear of the second bevel gear 4 on the rocker shaft 6 The bearing 26 is installed, and the bearing 26 is supported by a bearing seat welded on the furnace roof; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com