Experimental apparatus for evaluating coalbed methane cave well completion

An experimental device and coalbed methane technology, applied in construction and other fields, can solve problems such as time-consuming, difficult to explain and analyze the mechanism of production increase, and lack of fast, multiple, multi-layer experiments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

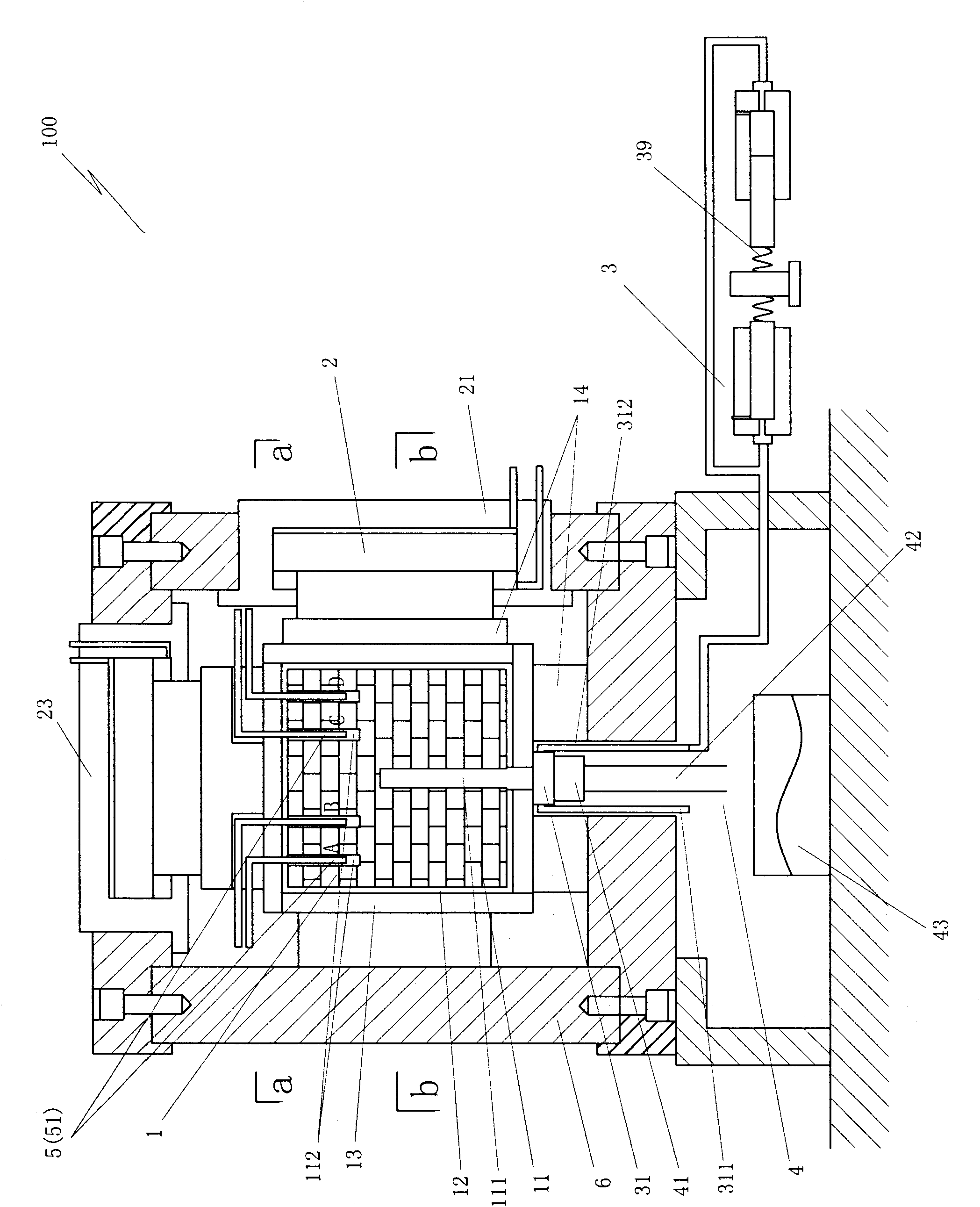

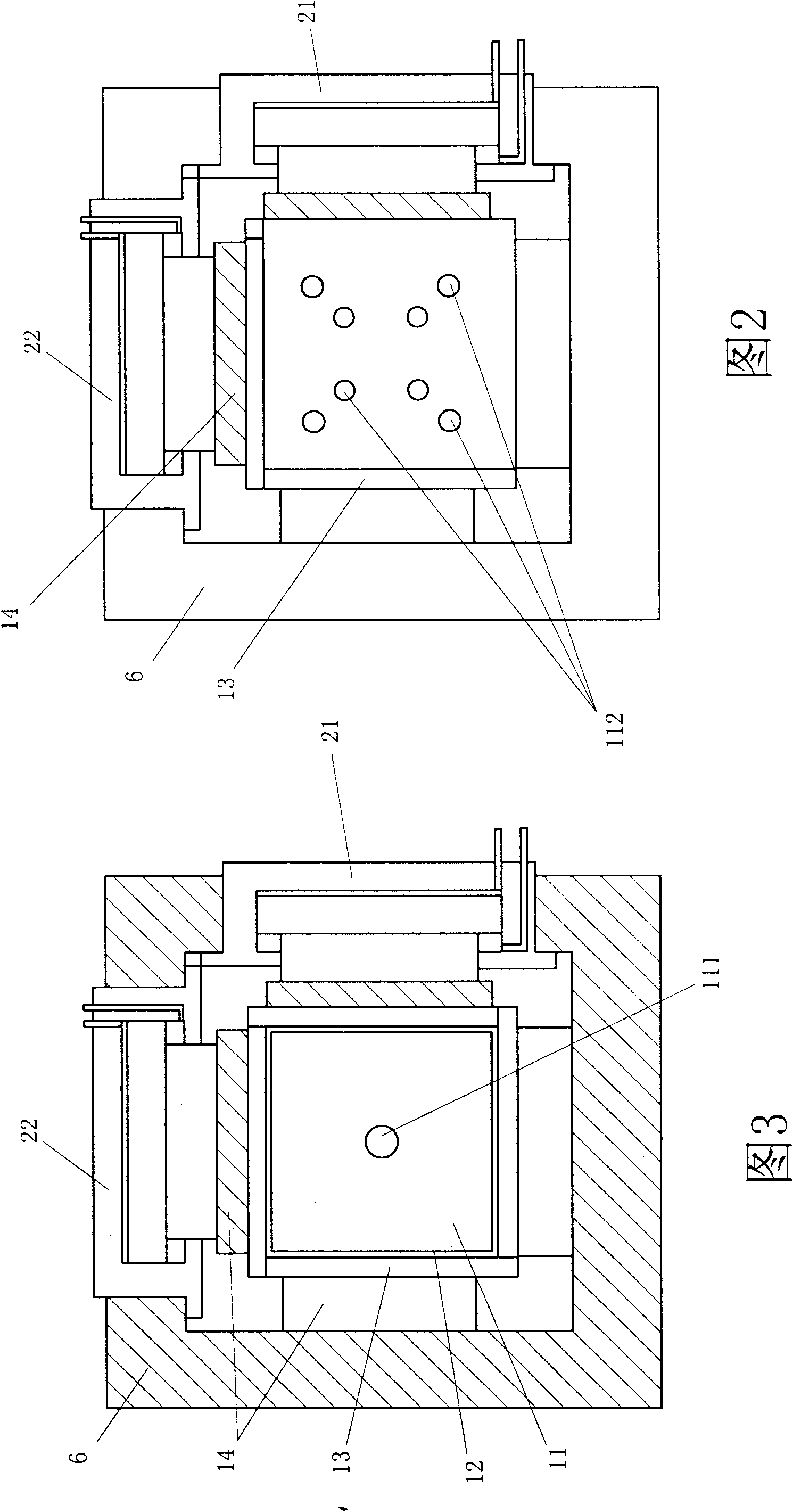

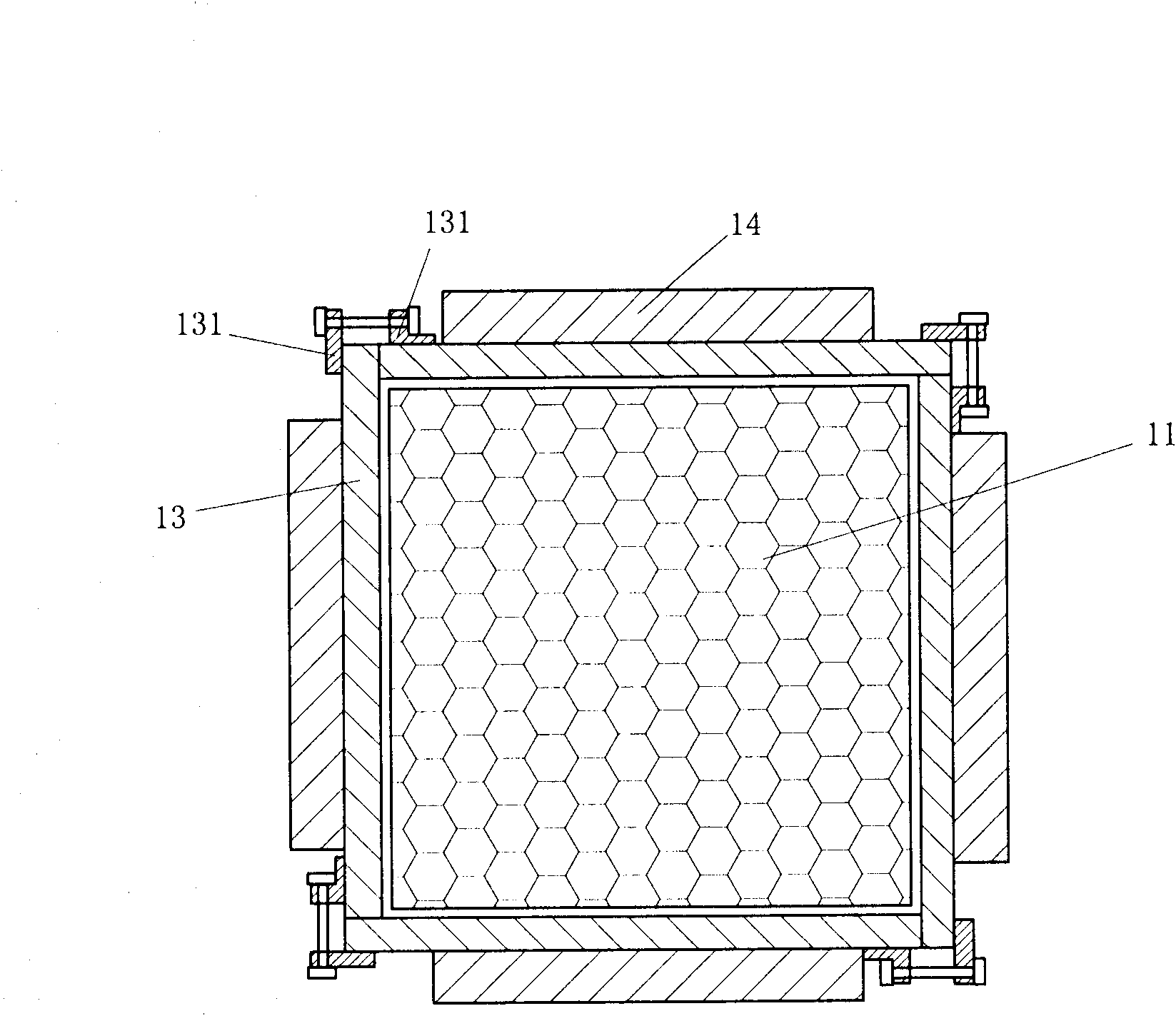

[0027] Such as Figure 1-Figure 7 As shown, the present invention proposes a coalbed methane cave completion evaluation test device 100, the evaluation test device 100 consists of a square coal rock model and its clamping system 1, a three-axis servo loading system 2, and a gas-liquid pressurized injection system 3 , a collection and measurement system 4 and a monitoring and processing system 5; the square coal rock model and its clamping system 1 are arranged in a frame 6, the square coal rock model and its clamping system 1 include a cube coal rock model 11, the The bottom surface of the coal-rock model 11 is provided with an upwardly extending simulated shaft 111, the top surface of the coal-rock model 11 is provided with a pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com