Method for preparing ethene by catalyzing ethanol dehydration

A technology of catalytic dehydration and ethanol aqueous solution, which is applied in the direction of hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., and can solve the problem of low catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

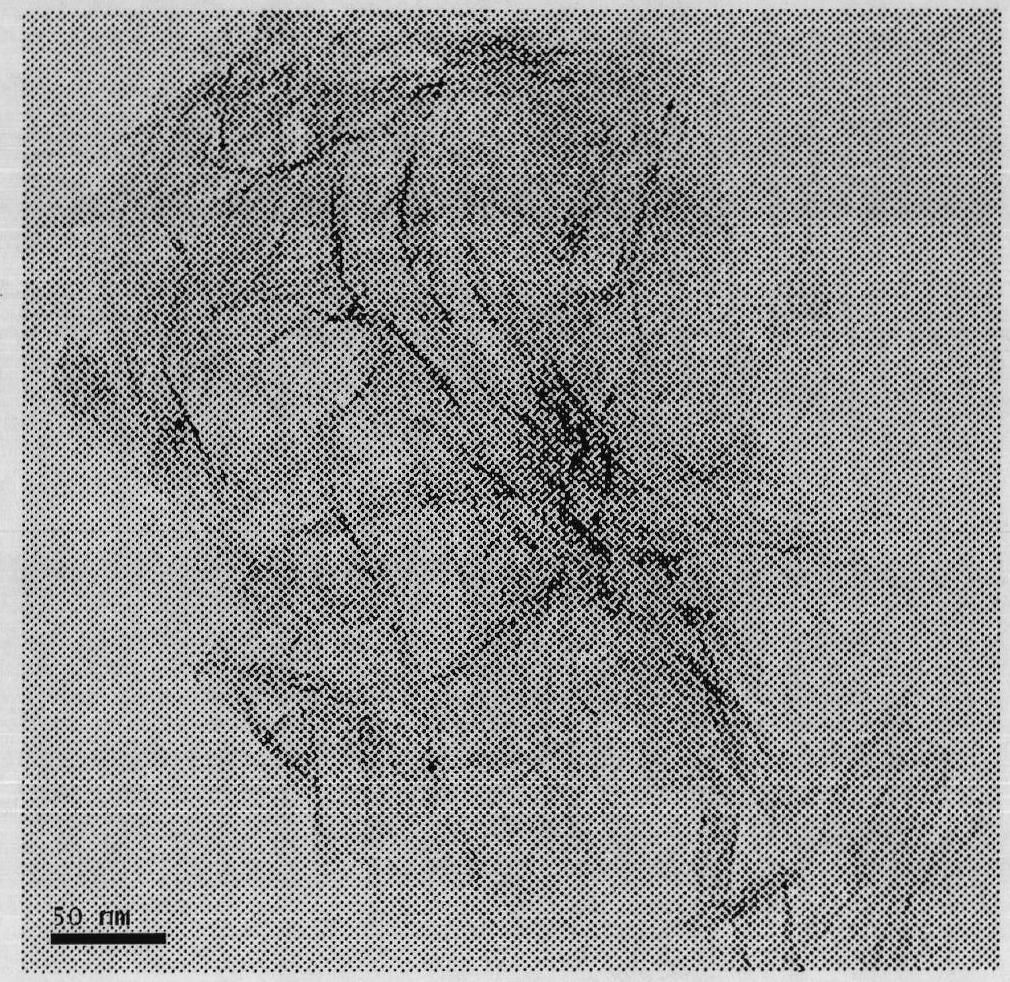

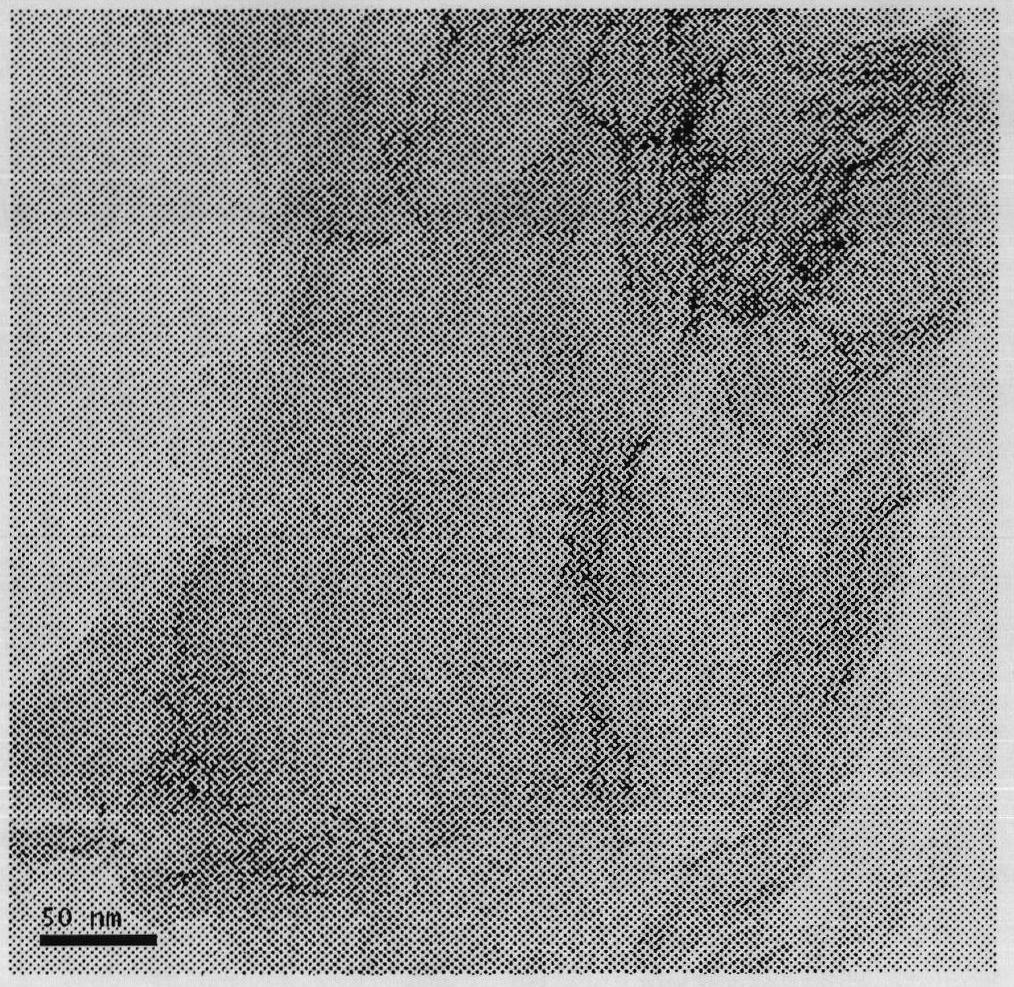

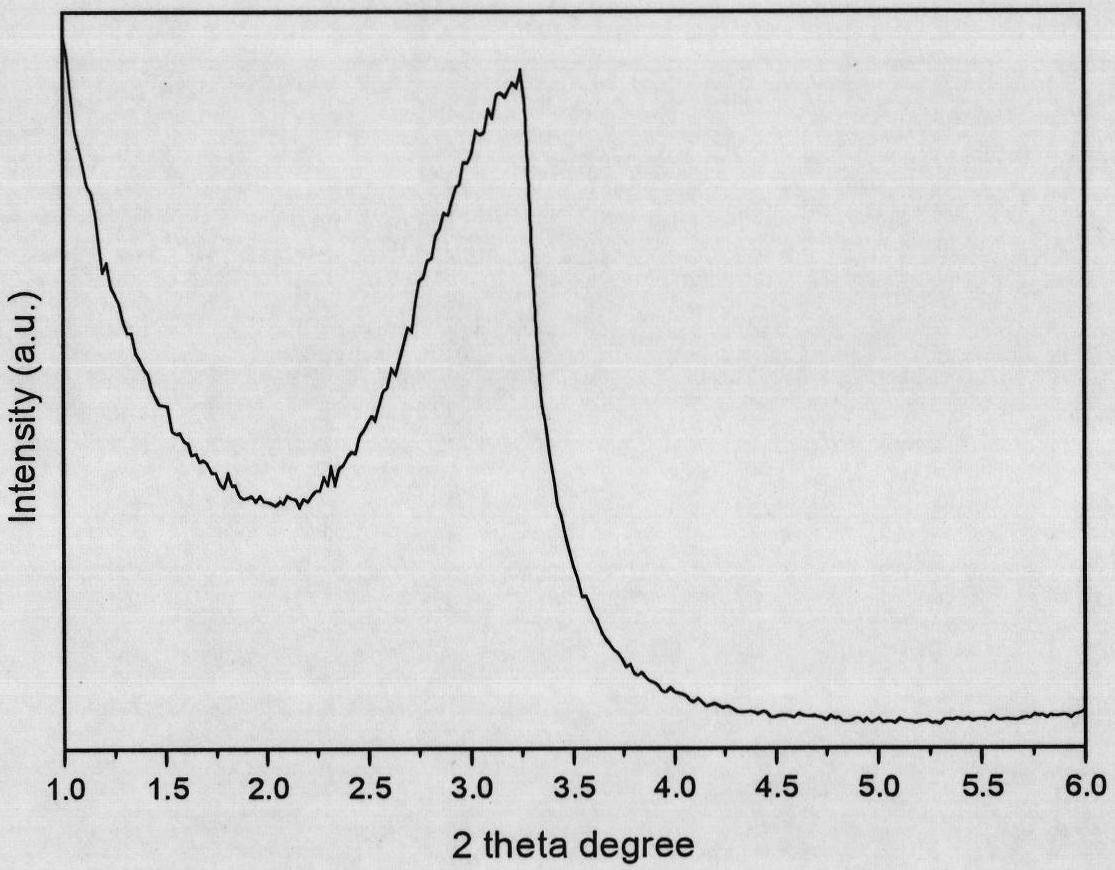

[0023] Get 11.5 grams of aluminum nitrate nonahydrate and dissolve it into 25 milliliters of water to obtain A solution, then get sodium dodecylsulfonate (C 12 ) 1.5 g was dissolved in 30 ml of water to obtain solution B, under stirring at 50°C, solution B was added dropwise to solution A, and stirred until a uniform gel-like product was obtained. Then 12 ml of 65-70% ethylamine aqueous solution was added dropwise to the above gel to obtain a precipitate. The precipitate was hydrothermally crystallized at 120°C for 4 days. The obtained solid product was washed with water until neutral, then washed four times with 95% ethanol, and dried in air at 50° C. to obtain surfactant-composite aluminum oxide nanotubes. Finally, it was calcined at 650° C. for 8 hours to obtain the finished catalyst.

Embodiment 2~9

[0025] The preparation conditions of other sulfonate-type anionic surfactants as templates are according to the steps of [Example 1]. The specific material ratio and preparation conditions are shown in Table 1.

Embodiment 10

[0026] [Example 10] Catalytic Performance Evaluation

[0027] The performance evaluation of the catalyst was carried out on a fixed-bed reaction device at normal pressure, using a stainless steel reactor with an inner diameter of 10 mm, the catalyst was the catalyst prepared in [Example 1], the loading capacity was 10 ml, the reaction temperature was 350 ° C, and the normal pressure Down reaction, raw material is 35% ethanol, space velocity 5 hours -1 . The reaction products were analyzed separately after gas-liquid separation, and the reaction results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com