Electrically-driven speed change device for vehicles

A speed change device and electric drive technology, which is applied in the direction of transmission device, gear transmission device, differential transmission device, etc., can solve the problems of complex structure and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

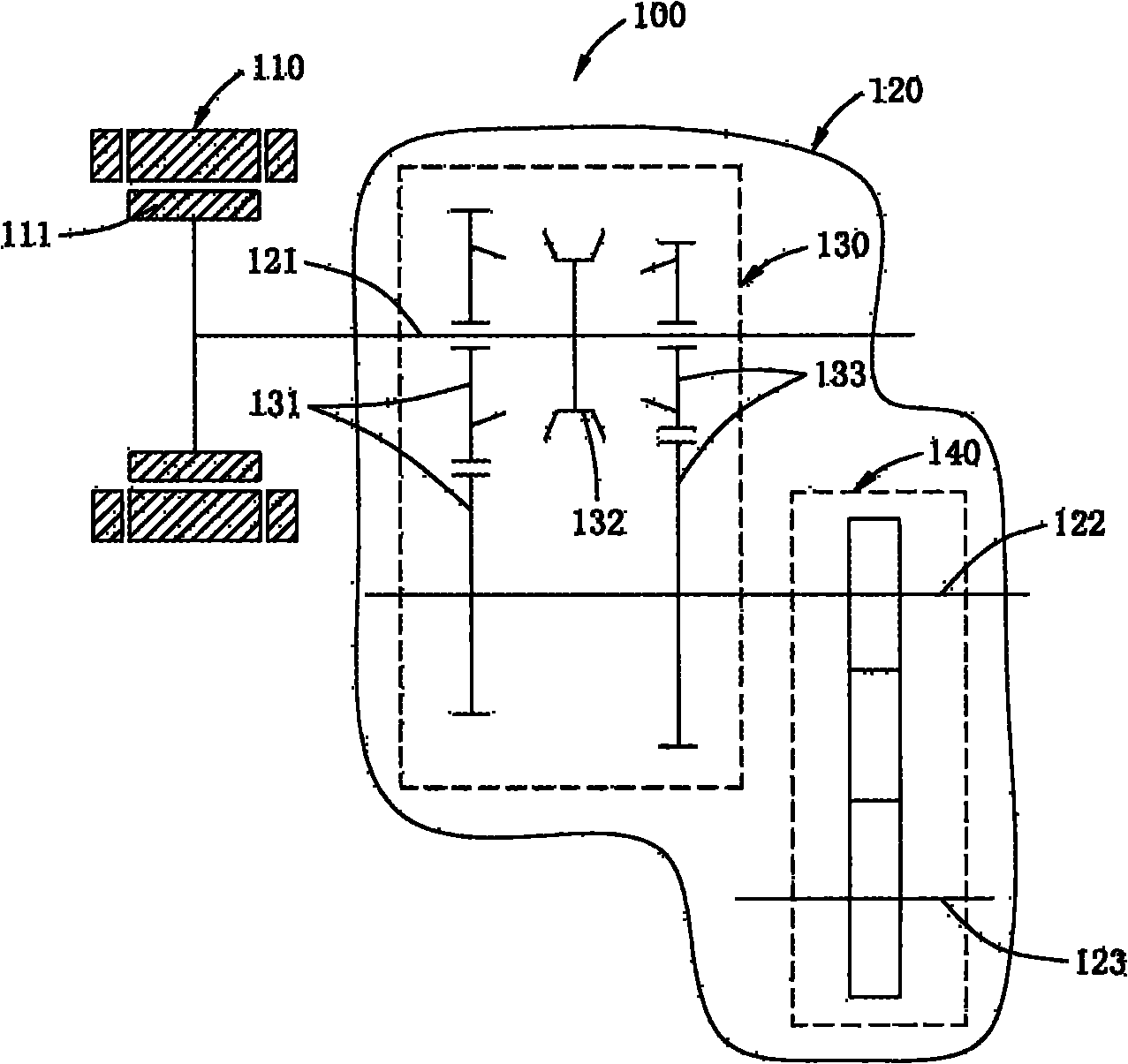

[0031] figure 2 A schematic diagram of a first embodiment of the electric drive transmission device for a vehicle according to the present invention is shown. exist figure 2 Among them, the electrically driven transmission device for a vehicle according to the present first embodiment is generally indicated by reference numeral 100 . As can be seen from the figure, the electric drive transmission device 100 for a vehicle according to the first embodiment includes a motor 110 and a transmission mechanism 120 . The motor 110 is indicated by hatching, the stator of the motor 110 is formed on the periphery thereof, and the rotor 111 of the motor 110 is formed on the inner periphery thereof. Transmission mechanism 120 is shown in the curve frame (this curve itself does not belong to the part of device of the present invention), and it comprises input shaft 121, speed change mechanism 130, intermediate shaft 122, reduction mechanism 140 and output shaft 123, and motor 110 compri...

no. 2 approach

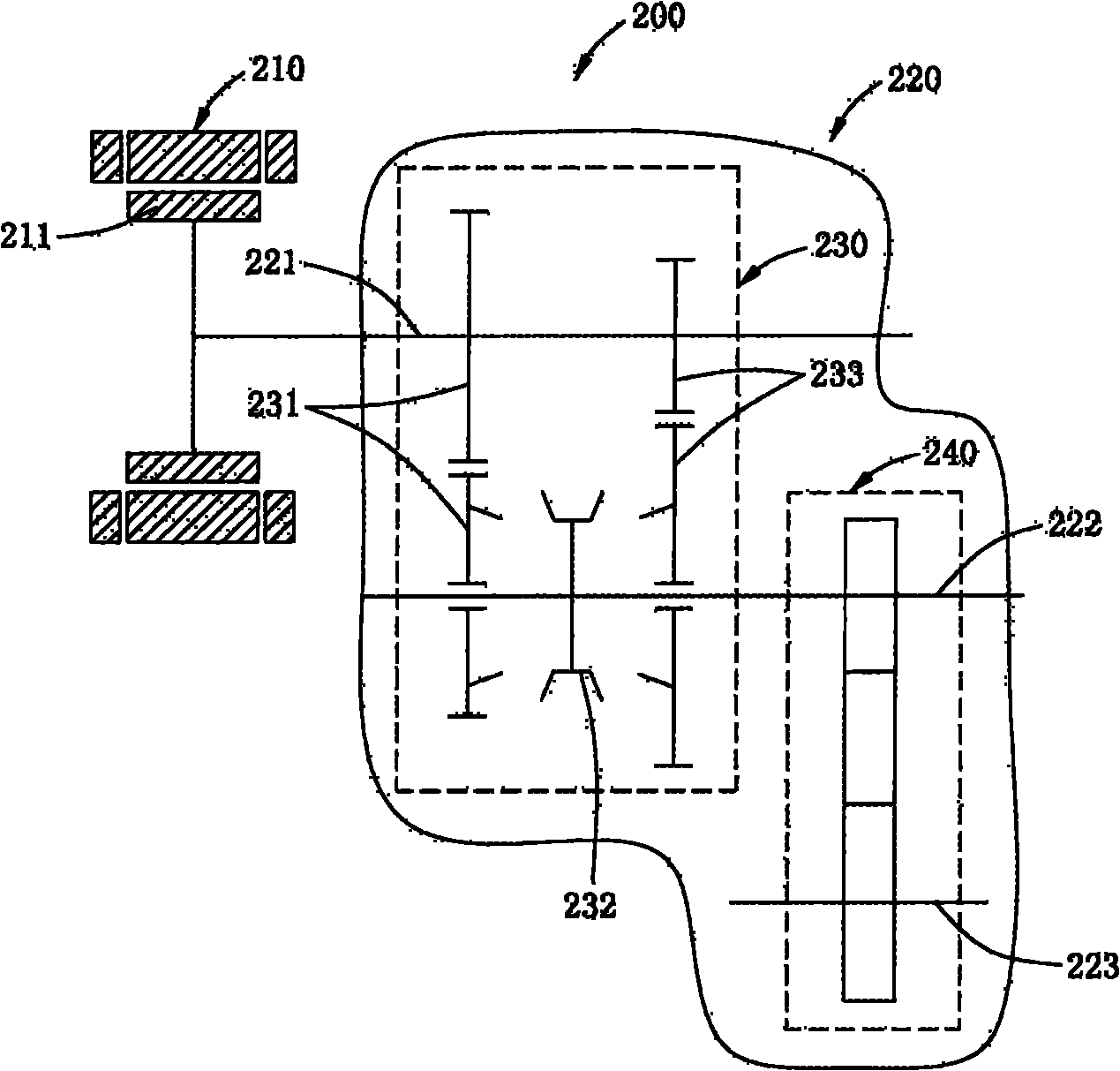

[0035] image 3 A schematic diagram of a second embodiment of the electric drive transmission device for a vehicle according to the present invention is shown. exist image 3 Among them, the electrically driven transmission device for a vehicle according to the present second embodiment is generally indicated by reference numeral 200 . It can be seen from the figure that the electric drive transmission device 200 for a vehicle according to the second embodiment includes a motor 210 and a transmission mechanism 220 . The motor 210 is indicated by hatching, the stator of the motor 210 is formed on the periphery thereof, and the rotor 211 of the motor 210 is formed on the inner periphery thereof. Transmission mechanism 220 is shown in the curve frame (this curve itself does not belong to the part of device of the present invention), and it comprises input shaft 221, speed change mechanism 230, intermediate shaft 222, reduction mechanism 240 and output shaft 223, and motor 210 c...

no. 3 approach

[0039] Figure 4 A schematic diagram of a third embodiment of the electric drive transmission device for a vehicle according to the present invention is shown. exist Figure 4 Among them, the electrically driven transmission device for a vehicle according to the present third embodiment is generally indicated by reference numeral 300 . As can be seen from the figure, the electric drive transmission device 300 for a vehicle according to the third embodiment includes a motor 310 and a transmission mechanism 320 . The motor 310 is indicated by hatching, the stator of the motor 310 is formed on the periphery thereof, and the rotor 311 of the motor 310 is formed on the inner periphery thereof. The transmission mechanism 320 is shown in the curve frame (this curve itself does not belong to a part of the device of the present invention), and it includes an input shaft 321, a speed change mechanism 330, an intermediate shaft 322, a reduction mechanism 340 and an output shaft 323, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com