Substrate manufacturing method

A manufacturing method and base technology, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of manufacturing difficulties, increasing the time of base manufacturing, hindering concrete pouring, etc., achieving accurate length and width dimensions, and exempting construction restrictions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

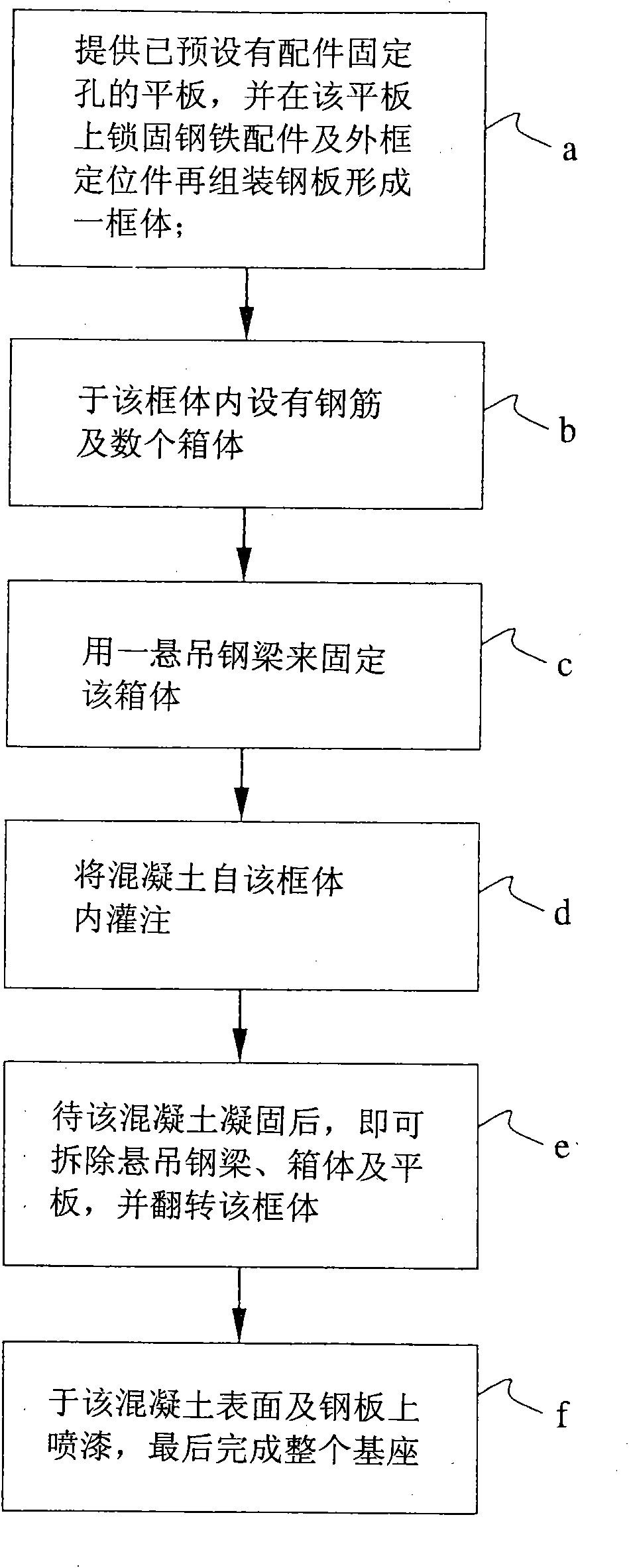

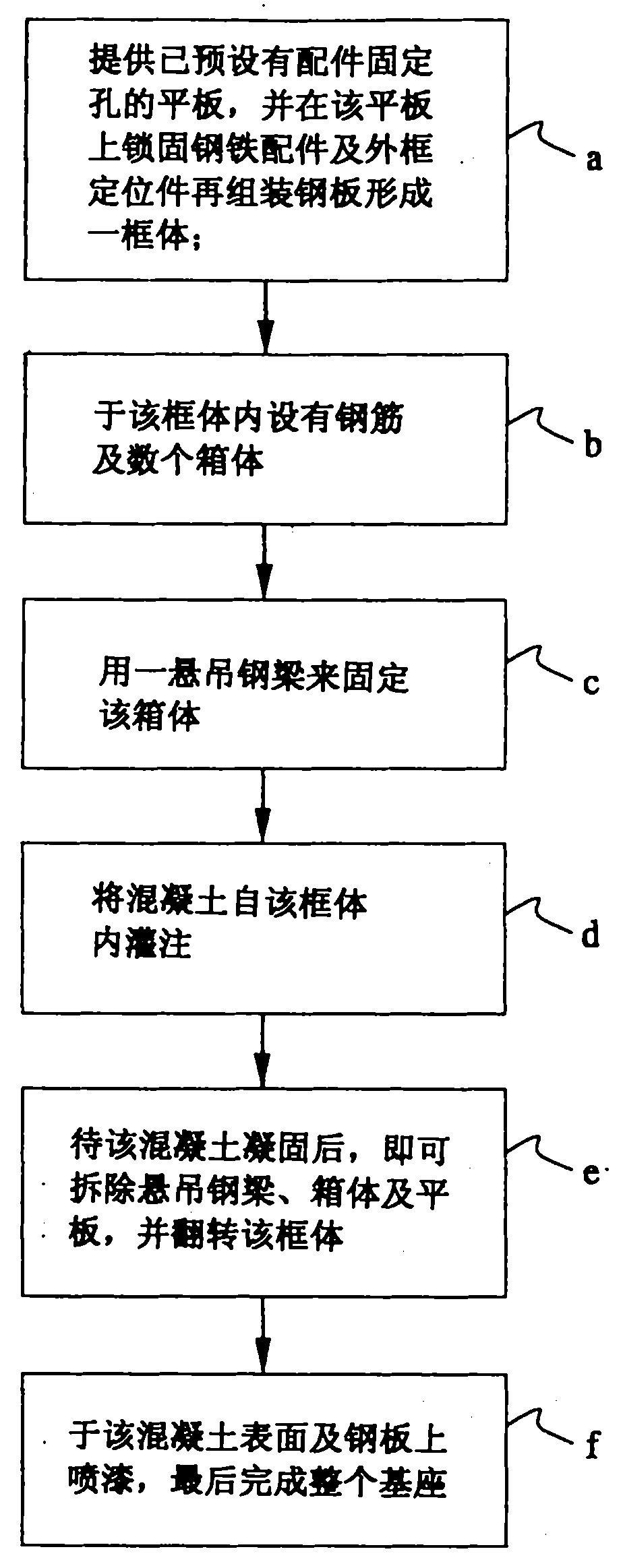

[0026] see figure 1 As shown, its manufacturing method is as follows:

[0027] a. Provide a plate with preset fixing holes for accessories, and lock the steel accessories and outer frame positioning parts on the plate, and then assemble the steel plates to form a frame;

[0028] b. Set several steel bars and several boxes in the frame;

[0029] c. Use a fixed suspension steel beam to fix the box;

[0030] d. Pour concrete into the frame;

[0031] e. After the concrete is solidified, the fixed suspension steel beams, boxes and slabs can be removed, and the frame can be turned over;

[0032] f. Spray paint on the concrete surface and steel plate, and finally complete the entire base.

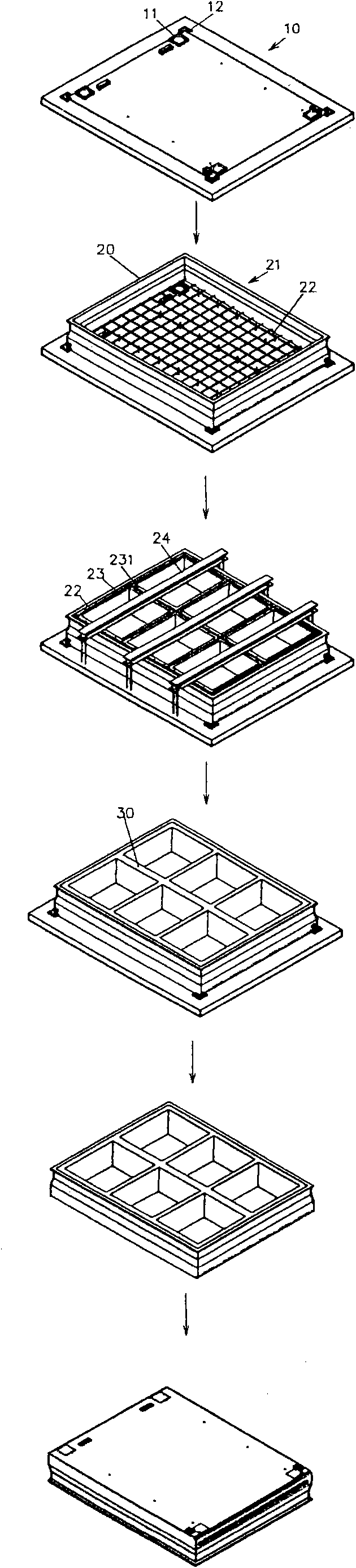

[0033] see figure 2 As shown, the flat plate 10 provided with a predetermined accessory fixing hole is preset with a steel fitting 11 and a steel plate fixing part 12, and the steel plate 20 is assembled on the flat plate 10, and the steel plate fixing part 12 fixes the steel plate 20, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com