Multi-beam plate leveller

A leveling machine and plate technology, applied in the field of forging equipment, can solve the problems of poor lateral force resistance of rollers and upper beams, unusable, limited beam width, etc., and achieve the effect of improving the leveling quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in conjunction with the accompanying drawings.

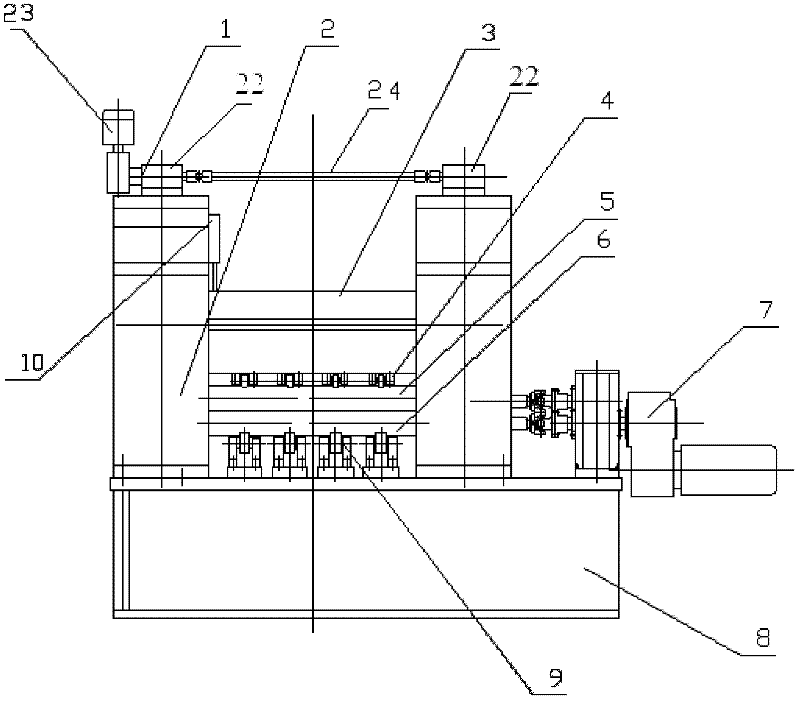

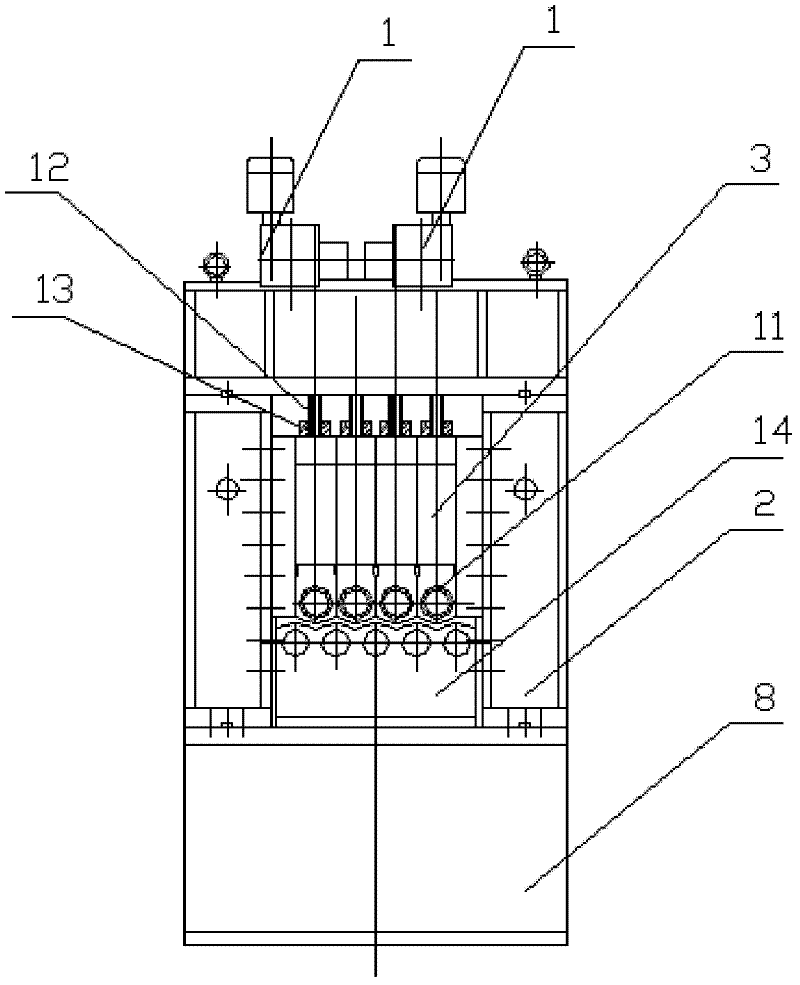

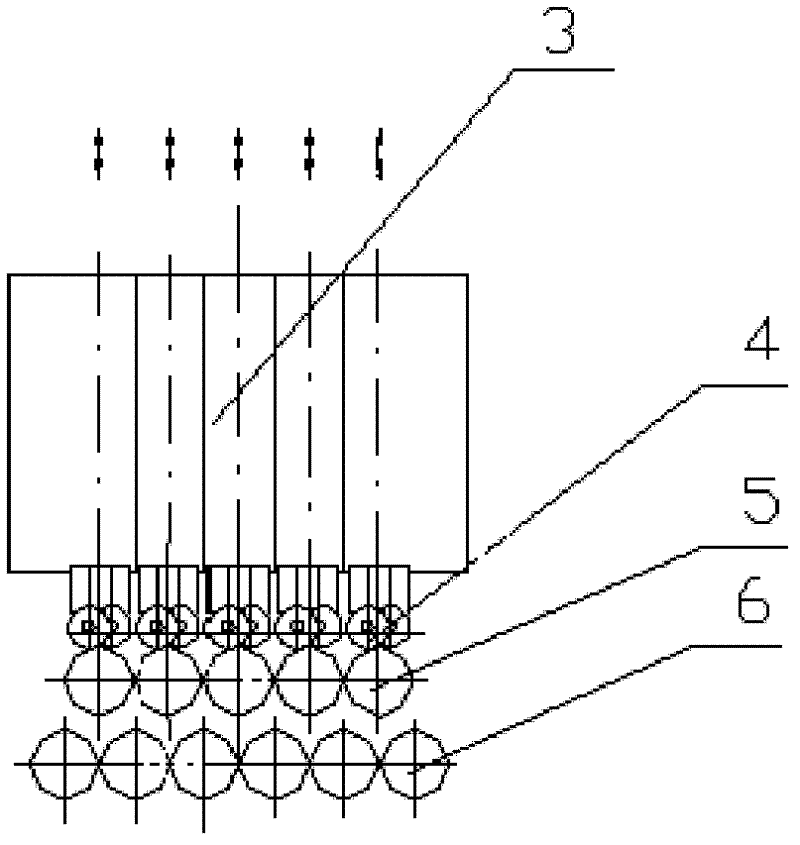

[0029] like figure 1 , 2 Shown: a multi-beam plate leveler, which includes a pressing mechanism 1, a frame 2, a single beam 3, an upper support roll 4, an upper work roll 5, a lower work roll 6, a main drive 7, and a bed 8 , the lower backup roll 9, the displacement measuring device 10, the upper roll bearing housing 11, the lower rolling bearing housing 14; Multiple sets of upper back-up rolls 4 are installed between the sheet beam 3 and the upper work roll 5, and all of them are arranged in a staggered manner. Each set of pressing mechanism 1 is composed of two screw rods 12, two nuts 13, two reducers 22, A driving motor 23 and a set of shaft coupling 24 are formed, and two speed reducers 22 of all pressing mechanisms are installed on the frame 2, and the driving motor 23 is directly connected with one of the speed reducers 22, and the two speed reducers 22 are connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com