Multifunctional non-basecoat coating machine

A technology without primer and coating machine, applied in the field of coating, to achieve the effect of low equipment procurement cost, saving of material consumption and electricity cost for drying treatment, and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

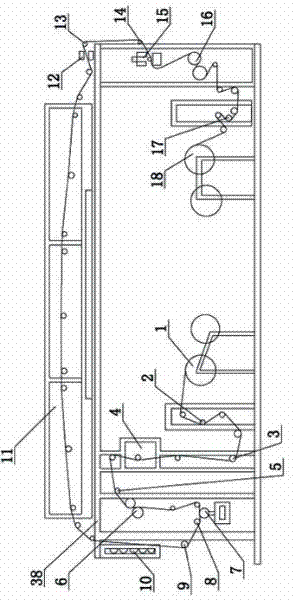

Embodiment 1

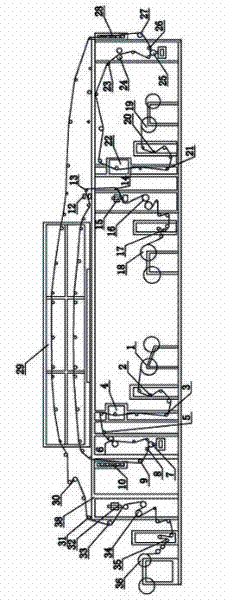

[0026] like figure 2 As shown, the first embodiment is repeated, with the following differences. One side of the fuselage 38 is provided with the third cooling roller device 30, the third deviation correction device 31, the fifth tension control and adjustment device 32, the second tightening compound device 33, the first Four cooling roller devices 34, the sixth tension control adjustment device 35 and the second winding device 36, the second heating and drying device 29 is set on the fuselage 38, and the second far-infrared processing device 28, the second far-infrared processing device 28, The second vacuum roll device 27, the second coating kiss roll device 26, the second coating device 25, the second cooling and clamping device 24, the seventh tension control and adjustment device 23, the second corona treatment device 22, the fourth deviation correction The device 21, the eighth tension control and adjustment device 20, the second unwinding device 19, and the second inf...

Embodiment 2

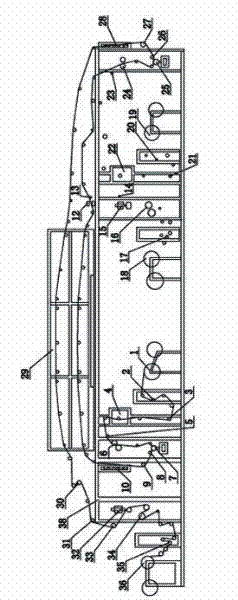

[0030] Embodiment four:

[0031] like image 3 Shown, repeat embodiment two, have the following difference, present embodiment is applicable to the production of coating film with primer single-side single-coating, specific technological process repeats embodiment three, difference is: the first coating device 7 directions The binder is coated on the coating material, and the second coating device 25 coats the polymer emulsion on the coating material coated with the binder.

Embodiment 3

[0033] like Figure 4 As shown, the second embodiment is repeated, with the following difference: the side of the fuselage 38 on which the second unwinding device 19 is provided is provided with an overturning device 37 . This embodiment is suitable for the production of coated films with double-sided double-coating without primer coating. The specific process flow is as follows: the coating material (film, paper, sheet, etc.) is placed on the first unwinding device 1, and drawn out, the coating material Lead out from the first unwinding device 1, after being stretched by the first tension control and adjusting device 2 to make the tension in a proper state, enter the first deviation correcting device 3 to correct the deviation, so that the coating material is in a straight line and stable running state, and then enter the first After the corona treatment device 4 performs corona treatment on the coating material, it enters the second tension control and adjustment device 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com