Crystallizing method utilizing external circulation of crystal slurry

A technology of external circulation and crystal slurry, which is applied in solution crystallization, crystallization purification/separation, organic chemistry, etc., can solve the problems of small crystal particle size and frequent crystallizer cleaning, and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

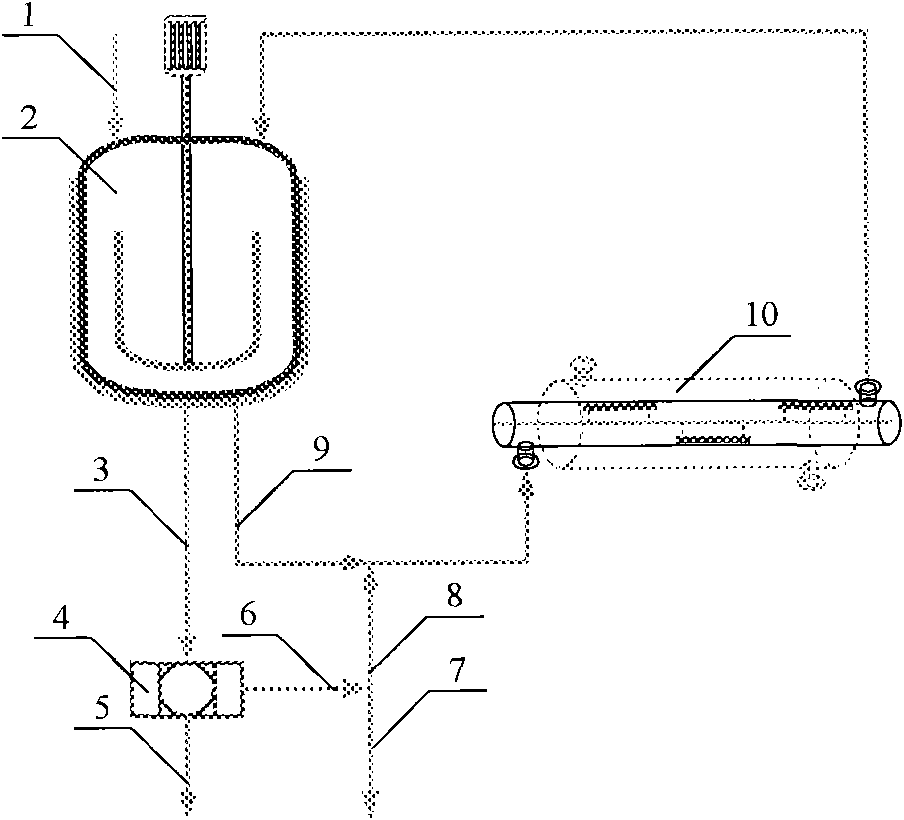

[0026] The crystallization method of outer circulation of magma slurry according to the present invention produces p-xylene

[0027] like figure 2 Said, mixed xylene raw material 1 contains 90% p-xylene, and the flow rate is 14864kg / h. The mixed xylene raw material 1 directly enters the kettle crystallizer 2 for crystallization, and the crystallization temperature is -14.5°C. The magma in the tank crystallizer 2 is divided into two parts: magma 3 and magma 9 to flow out. Crystal slurry 3 is separated by centrifugal filter 4 to obtain p-xylene crystals 5 and mother liquor 6 for crystallization and filtration. The p-xylene crystals 5 are discharged as products after being washed by the pure p-xylene melt. The crystallization filtration mother liquor 6 is divided into two shares, and the crystallization filtration mother liquor 7 accounting for 11% by weight of the first share is discharged, and the crystallization filtration mother liquor 8 accounting for 89% by weight of th...

Embodiment 2

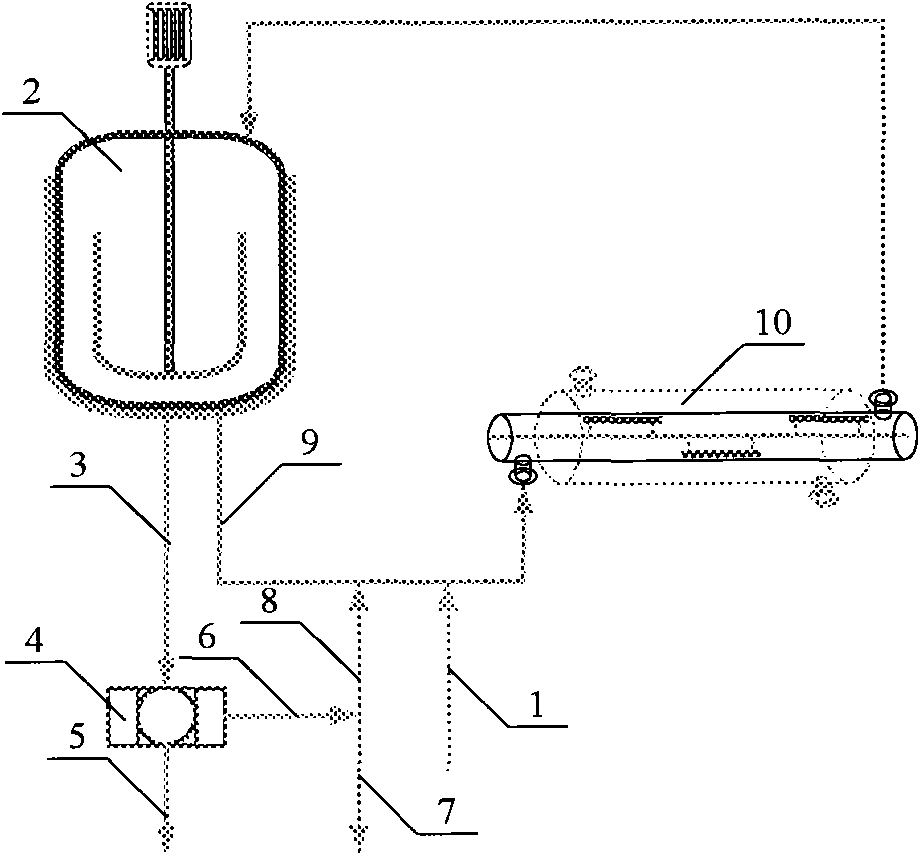

[0029] The crystallization method of outer circulation of magma slurry according to the present invention produces p-xylene

[0030] use as image 3 The crystallization method of the external circulation of the magma, wherein the mixed xylene raw material 1 is mixed with the second crystallization and filtration mother liquor 8 and a part of the magma 9 in the kettle crystallizer and then enters the casing type crystallizer 10, and the solid-liquid Separator 4 is a crystal washing tower, and p-xylene crystal 5 is discharged as a product after being washed with pure toluene. All the other operating conditions are the same as in Example 1, and the results are listed in Table 1.

[0031] Table 1

[0032]

Embodiment 3

[0037] The crystallization method of outer circulation of magma slurry according to the present invention produces p-xylene

[0038] use as figure 2 The crystallization method of the external circulation of the magma, wherein the sleeve-type crystallizer 10 is composed of a tube-type heat exchanger with a scraper, the operating temperature is -17.5 ° C, and the remaining operating conditions are the same as in Example 1. The results Listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com