Method for separating beeswax in propolis through supercritical CO2

A supercritical and propolis technology, which is applied to the recovery/refining of medical preparations containing active ingredients, pharmaceutical formulas, and fatty substances. It can solve the problems of active ingredient reduction and quality reduction of propolis extracts, and achieve the effect of improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

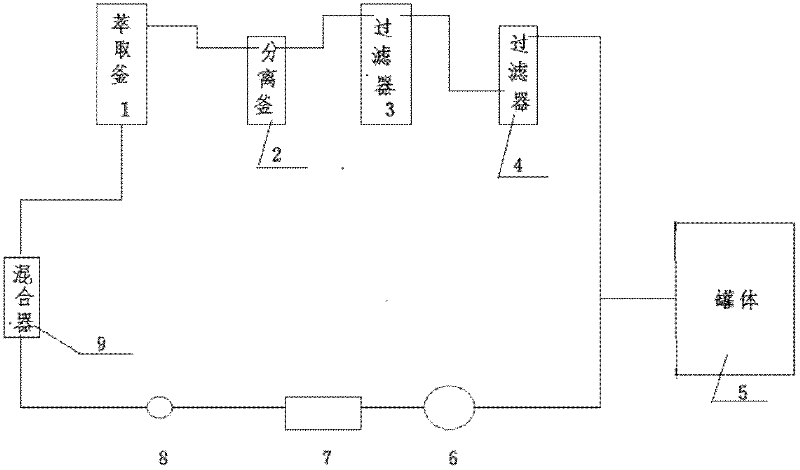

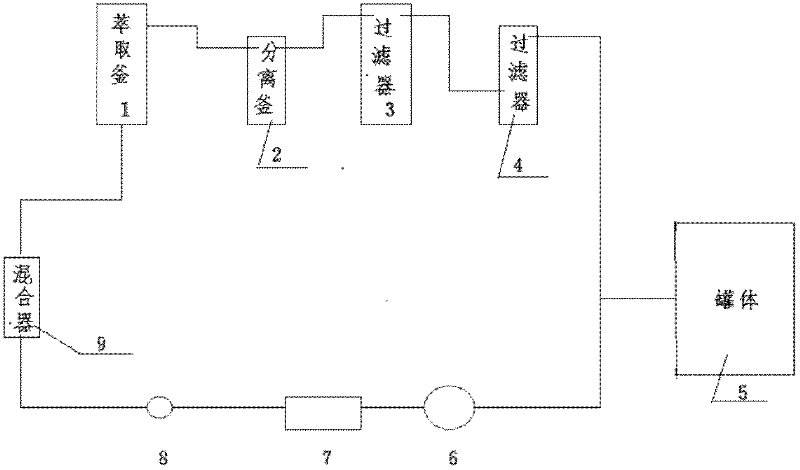

[0017] Weigh 500g of propolis, freeze and pulverize to 14 mesh to form powder, put the propolis pulverized into powder into extraction kettle 1, pass into supercritical CO 2 The fluid is extracted under the conditions of extraction pressure 10Mpa and extraction tank temperature 34°C, and then separated in the separation tank 2 under the conditions of separation pressure 8Mpa and separation temperature 45°C, supercritical CO 2 The flow rate of fluid is 320L / h, and after extracting 1 hour, emits pure white beeswax in separating kettle 2, and beeswax total amount is 130g, and the separated CO 2 The gas is filtered through two-stage filters 3 and 4 to filter out impurities to obtain pure CO 2 Gas, for re-use, CO 2 The gas is then pressurized by the compressor 6, and after being cooled by the cold box 7, the tank body 5 is recycled through the high-pressure pump 8 and the mixer 9. The separation rate of beeswax refers to the proportion (weight ratio) of the separated beeswax in t...

Embodiment 2

[0020] Weigh 500g of propolis, freeze and pulverize to 14 mesh to form powder, put the propolis pulverized into powder into extraction kettle 1, pass into supercritical CO 2 The fluid is extracted under the conditions of extraction pressure 15Mpa and extraction temperature 36°C, and then separated in the separation tank 2 under the conditions of separation pressure 10Mpa and separation temperature 48°C, supercritical CO 2 The flow rate of fluid is 350L / h, and after extracting for 2 hours, the separation kettle emits pure white beeswax, the total amount of beeswax is 145g, and the separated CO 2 The gas is filtered through two-stage filters 3 and 4 to filter out impurities to obtain pure CO 2 Gas, for re-use, CO 2 The gas is then pressurized by the compressor 6, cooled by the cold box 7, and recycled by the high-pressure pump 8 and the mixer 9.

[0021] Performance index: The separation rate of beeswax reaches 97%, and the content of flavonoids and terpenes is zero.

Embodiment 3

[0023] Weigh 500g of propolis, freeze and pulverize to 14 mesh to form powder, put the propolis pulverized into powder into extraction kettle 1, pass into supercritical CO 2 The fluid is extracted under the conditions of extraction pressure 20Mpa and extraction temperature 40°C, and then separated in the separation tank 2 under the conditions of separation pressure 10Mpa and separation temperature 50°C, supercritical CO 2 The flow rate of fluid is 350L / h, and after extracting for 2 hours, the separation kettle emits pure white beeswax, the total amount is 215g, and the separated CO 2 The gas is filtered through two-stage filters 3 and 4 to filter out impurities to obtain pure CO 2 Gas, for re-use, CO 2 The gas is then pressurized by the compressor 6, cooled by the cold box 7, and recycled by the high-pressure pump 8 and the mixer 9.

[0024] Performance indicators: The separation rate of beeswax is greater than 100%, which contains a small amount of flavonoids and terpenes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com