Device for positioning and heating disc-shaped parts of clutch

A clutch disc and heating device technology, applied in the field of disc-shaped parts heating, can solve the problems of inaccurate control of parts heating time, affecting the processing quality of disc-shaped parts, uneven heating, etc., achieving easy control of heating time, remarkable energy-saving effect, The effect of improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

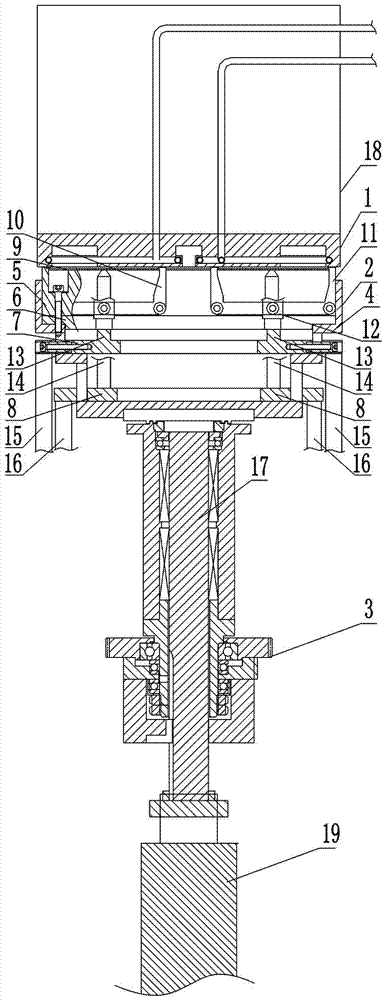

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] like figure 1 As shown, a clutch disc-shaped parts positioning heating device, it includes a heater 1, a tray 2 and a base 3, the tray 2 is installed on the base 3, and the tray 2 is located below the heater 1, the tray 2 includes a side wall in the form of Step-shaped shell 4, the interior of the shell 4 is provided with a workpiece kettle 5, a jaw seat 6, a lifting seat A7, and a lifting seat B8 sequentially along the direction from top to bottom.

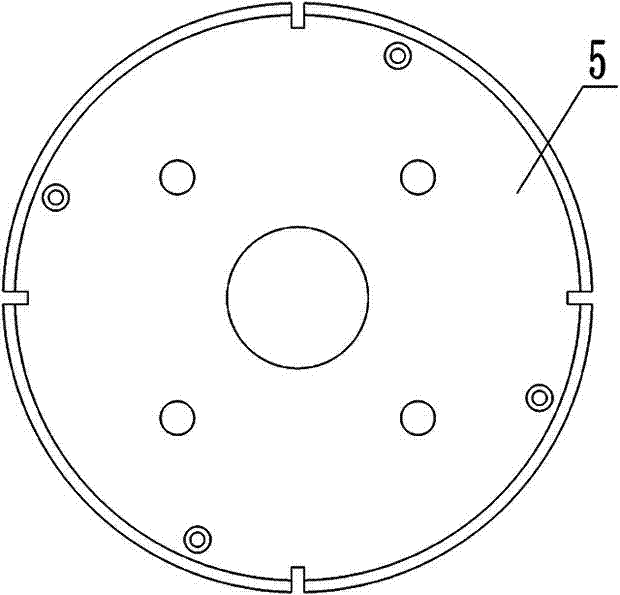

[0028] like figure 2 As shown, the workpiece kettle 5 is provided with a plane A9, the center of which is provided with a through hole, and the four sides of the through hole and the outer wall are provided with grooves that cooperate with the claws. The through hole that rod 14 matches;

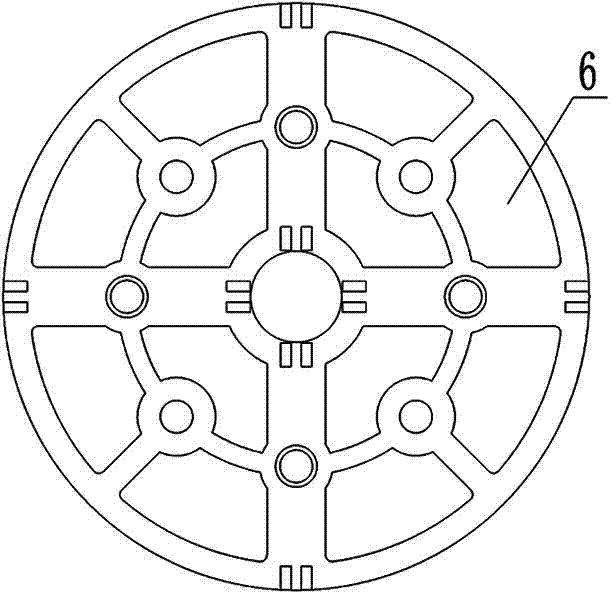

[0029] like figure 1 , image 3 As shown, four inner jaws 10 and four outer jaws 11 corresponding to the inner jaws 10 are ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com