Three-cavity vacuum tube

A vacuum tube and glass core technology, applied in solar thermal power generation, heating devices, solar thermal devices, etc., can solve the problems of insufficient use of hot water, large heat capacity of all-glass vacuum tubes, heat loss, etc. The effect of reducing heat loss and reducing heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

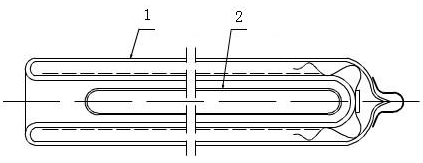

[0009] Such as figure 1 As shown, the present invention includes an all-glass vacuum tube 1 and a glass core tube 2. The glass core tube 2 is closed and installed inside the all-glass vacuum tube 1, so that the water capacity in the all-glass vacuum tube 1 is reduced, thereby reducing heat loss. The heat exchange speed is accelerated, and the heat loss caused by the water stored in the all-glass vacuum tube 1 is also reduced.

[0010] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Anyone familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Any equivalent replacement or change of the inventive concepts thereof shall fall within the protection scope of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com