Linear roller guide rail pair inverter

A technology of roller linear guide and reverser, which is applied in the direction of belt/chain/gear, mechanical equipment, transmission device, etc. Improves motion fluidity, reduces collisions, and reduces motion noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation manner.

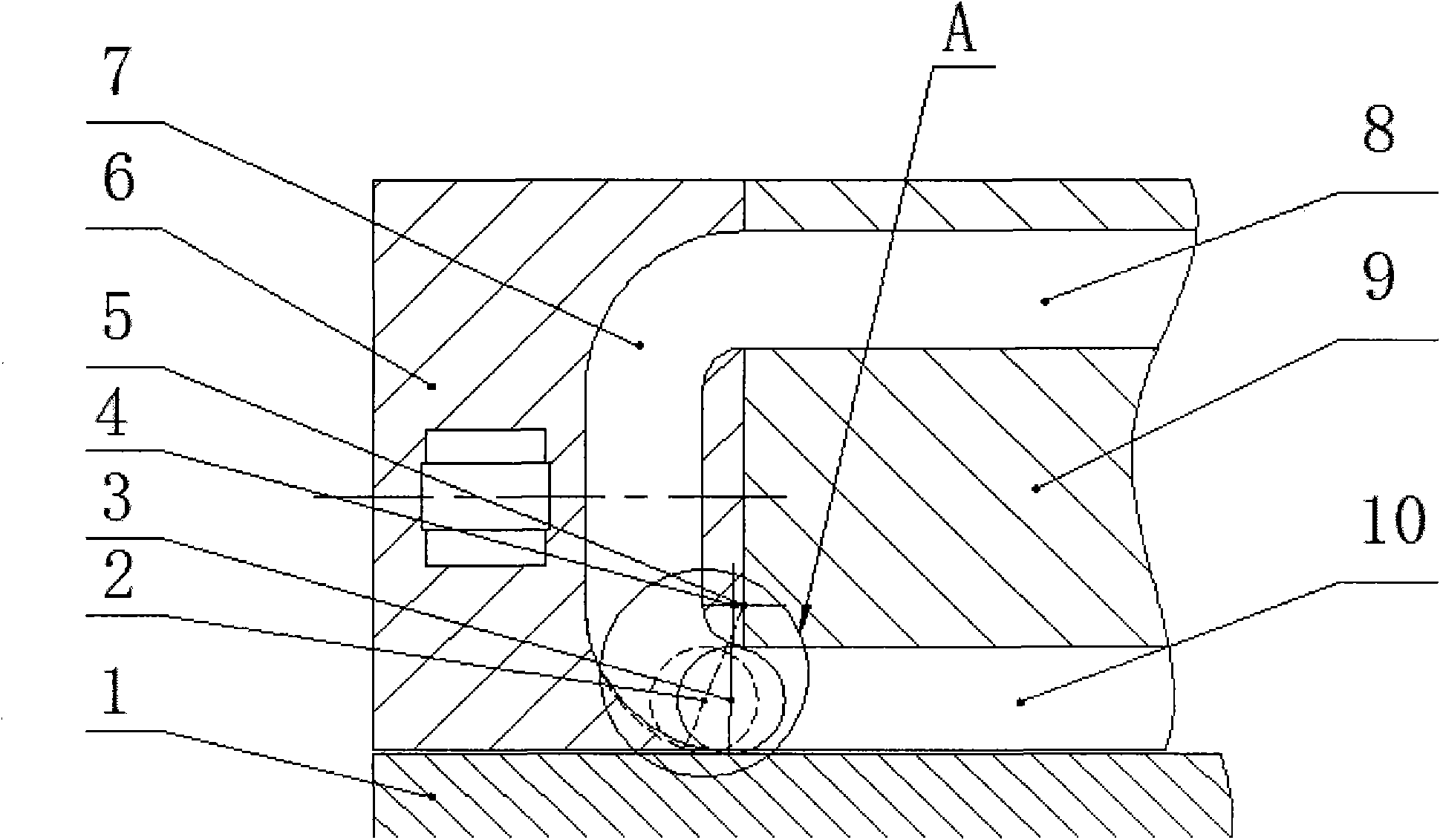

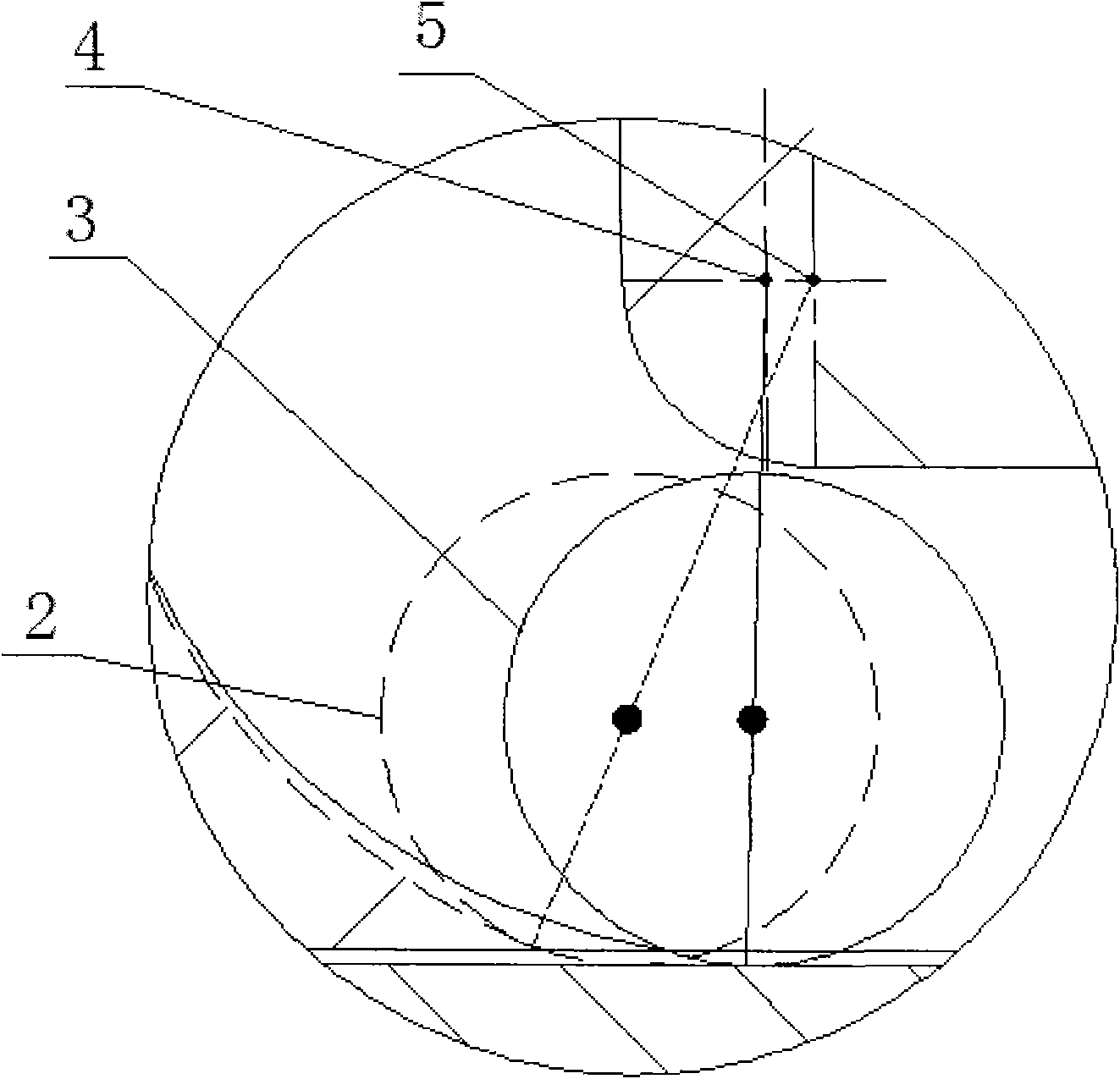

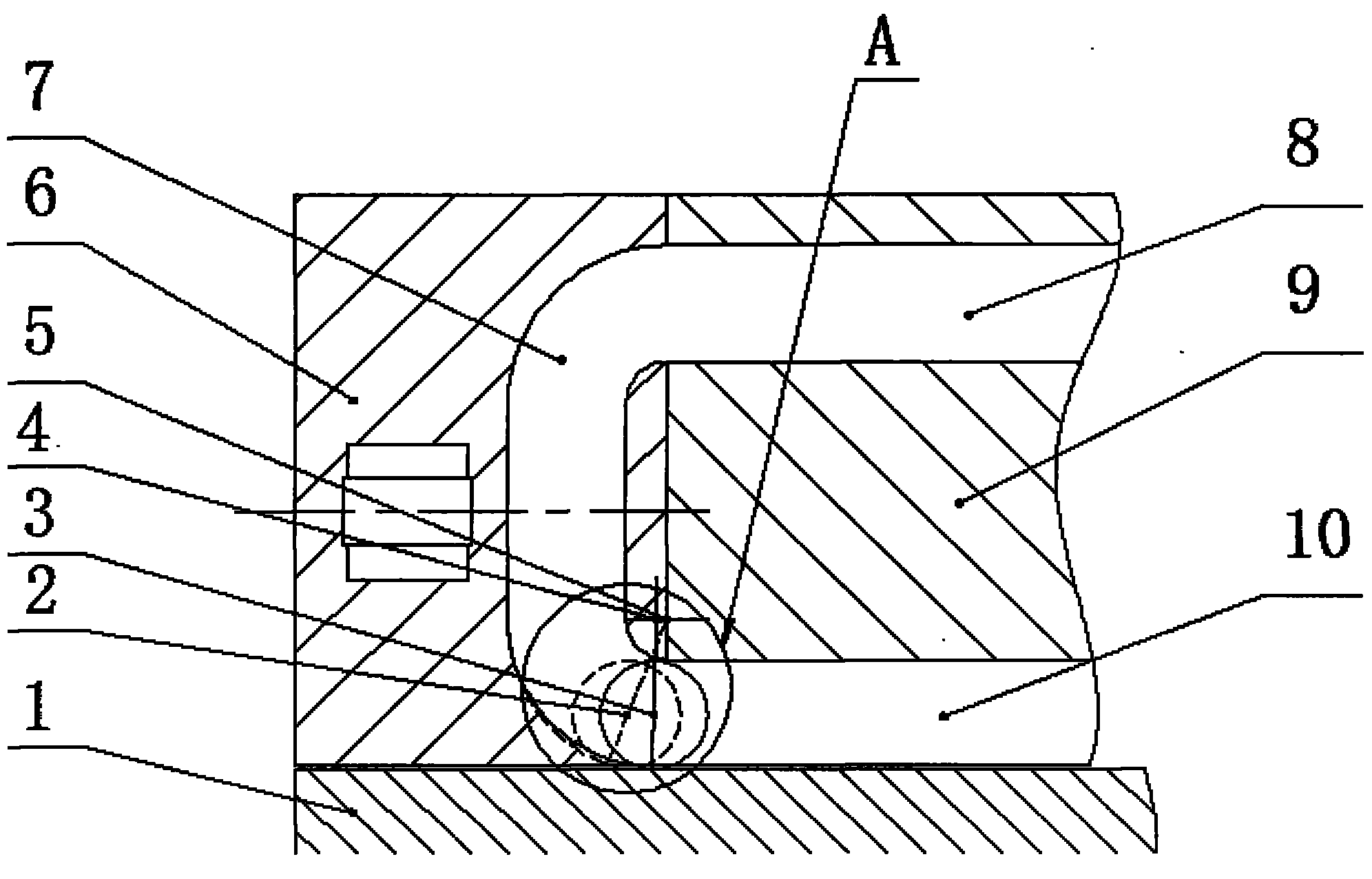

[0012] As shown in the figure, the present invention is a roller linear guide reverser, which includes a reverser body 6, a reverse channel, and the reverse channel includes a straight channel 7 and a reverse transition zone, and the straight channel 7 The width is greater than the width of the bearing area 10 on the slider 9 , and the reverse transition area smoothly transitions from the same width as the straight channel 7 to the same width as the bearing area 10 on the slider 9 . like figure 1 , figure 2 As shown by the dotted line in , the reverse transition zone realizes a smooth transition from the same width as the straight channel 7 to the smooth transition with the slider 9 by shifting the center 5 of the reverse outer arc in the prior art to the side of the straight channel 7 for a certain distance. The uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com