Flat plate type redox flow battery

A flow battery, configuration-type technology, applied in fuel cell additives, indirect fuel cells, etc., can solve problems such as increased power consumption, battery cell leakage, and increased electrolyte circulation pump infusion resistance, reducing Liquid junction current, the effect of increasing degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

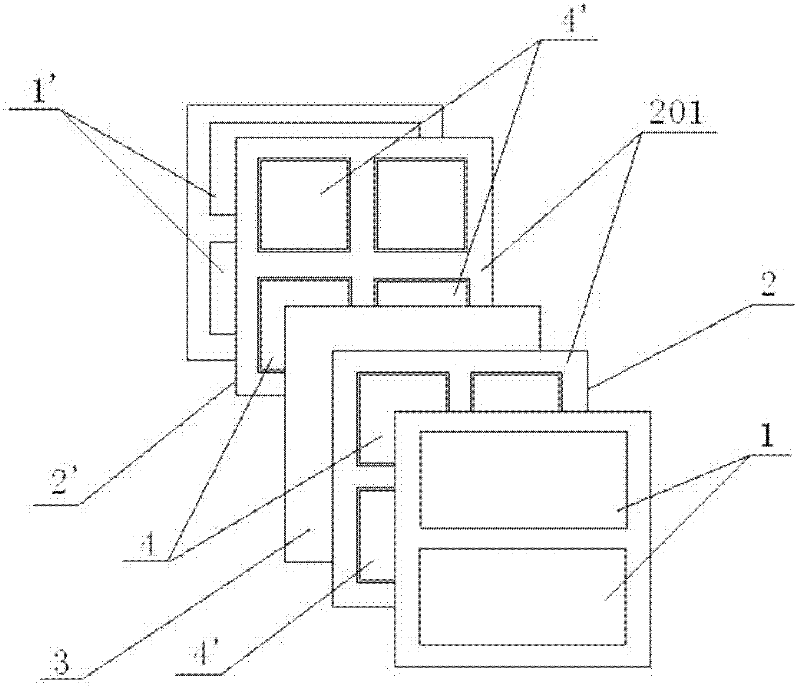

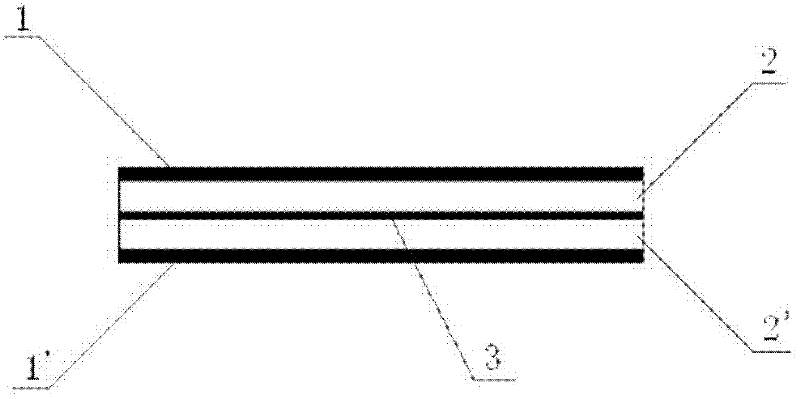

[0023] Such as figure 1 and figure 2 As shown, a redox flow battery with a flat plate configuration includes an electrolytic cell, a reaction electrode, a power supply electrode and a separation membrane, and is characterized in that, from top to bottom, the upper power supply electrode 1, the upper side electrolytic cell 2, and the separation membrane are sequentially separated. The membrane 3, the lower electrolytic cell 2' and the lower power supply electrode 1' are stacked. The electrolytic cells 2, 2' are separated into four electrolytic chambers arranged in a square shape by the electrolytic frame 201. In the upper electrolytic cell 2 Two pairs of positive reaction electrodes 4 and negative reaction electrodes 4' are arranged crosswise in the four electrolytic chambers, and two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com