Clean pulp preparation process for high-whiteness and high-strength chemical straw pulp

A clean pulping and high-strength technology, which is applied in the pulping of cellulose raw materials, textiles and papermaking, papermaking, etc., to achieve the effects of low pulping cost, light environmental pollution and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

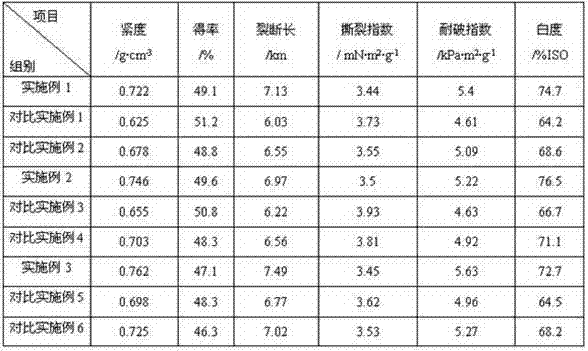

Examples

Embodiment 1

[0024] (1) The raw material is wheat straw, which is cut to a length of 1-4 cm with a hay cutter, and the dust is removed while cutting the grass, and then water, sodium hydroxide, hydrogen peroxide and metal ion chelating agent are added, and the amount of sodium hydroxide is the weight of wheat straw 5% of the weight of wheat straw, the amount of hydrogen peroxide is 10% of the weight of wheat straw, the liquid ratio is 1:4, the amount of metal ion chelating agent is 0.5% of the weight of wheat straw, after the temperature is kept at 75 ° C for 50 minutes, stop heating and complete the first step cooking to obtain cooking liquid;

[0025] (2) Open the cooking pot and add water, sodium hydroxide, hydrogen peroxide and metal ion chelating agent to the cooking liquid. The amount of sodium hydroxide is 10% of the weight of wheat straw, and the amount of hydrogen peroxide is 24% of the weight of wheat straw. The ratio is 1:4, the amount of metal ion chelating agent is 0.6% of the...

Embodiment 2

[0031] (1) The raw material is rice straw, which is cut to a length of 1-4 cm with a hay cutter, and the dust is removed while cutting grass, and then water, sodium hydroxide, hydrogen peroxide and metal ion chelating agent are added, and the amount of sodium hydroxide is the weight of rice straw The amount of hydrogen peroxide is 10% of the weight of rice straw, the liquid ratio is 1:5, and the amount of metal ion chelating agent is 0.6% of the weight of rice straw. After the temperature is kept at 80°C for 60 minutes, the heating is stopped and the first stage is completed. step cooking to obtain cooking liquid;

[0032] (2) Open the cooking pot and add water, sodium hydroxide, hydrogen peroxide and metal ion chelating agent to the cooking liquid. The amount of sodium hydroxide is 10% of the weight of rice straw, and the amount of hydrogen peroxide is 20% of the weight of rice straw. The ratio is 1:6, the amount of metal ion chelating agent is 0.8% of the weight of the straw...

Embodiment 3

[0038] (1) Reeds are used as raw materials, cut to a length of 1-4 cm with a hay cutter, dust is removed while cutting, and then water, sodium hydroxide, hydrogen peroxide and metal ion chelating agent are added. The amount of sodium hydroxide is 1 / 2 of the weight of reeds 10%, the amount of hydrogen peroxide is 24% of the weight of the reed, the liquid ratio is 1:5, and the amount of metal ion chelating agent is 0.8% of the weight of the reed. After the temperature is kept at 70°C for 60 minutes, stop heating and complete the first step. Cooking to obtain cooking liquid;

[0039] (2) Open the cooking pot and add water, sodium hydroxide, hydrogen peroxide and metal ion chelating agent to the cooking liquid. The amount of sodium hydroxide is 6% of the weight of the reed, and the amount of hydrogen peroxide is 12% of the weight of the reed. The ratio is 1:4, the amount of metal ion chelating agent is 0.5% of the reed weight, and the temperature is kept at 95°C for 1 hour to comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com