Electric cabinet cover plate

A technology of electric control box and cover plate, applied in electrical components, substation/switch layout details, cooling/ventilation of substation/switchgear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The core of the present invention is to provide a cover plate of the electric control box, the structure strength of the cover plate of the electric control box is relatively high.

[0024] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

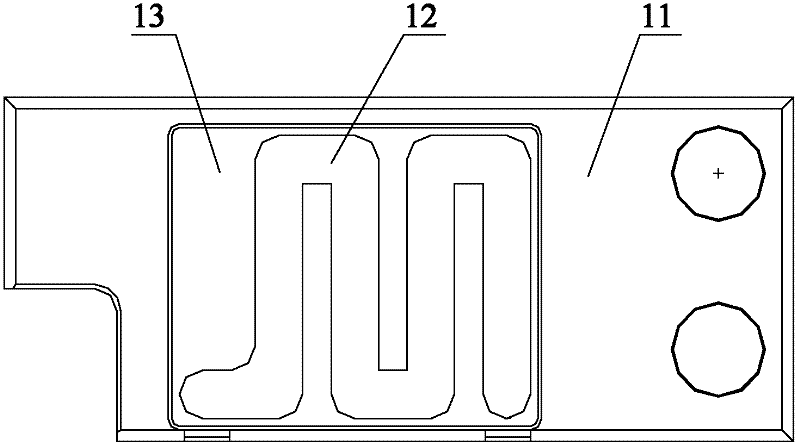

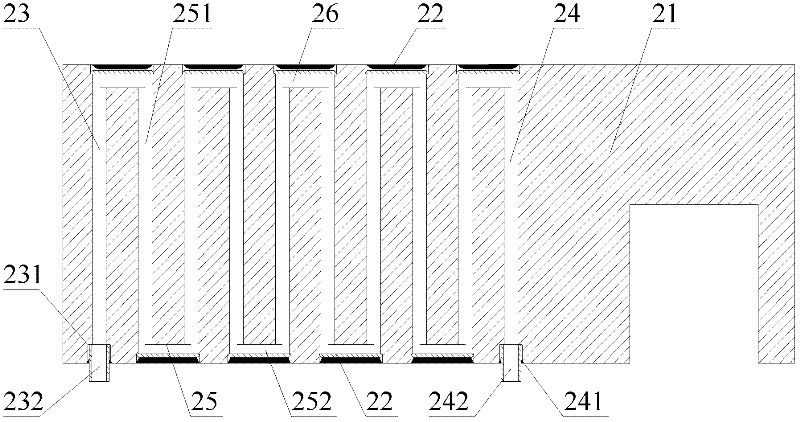

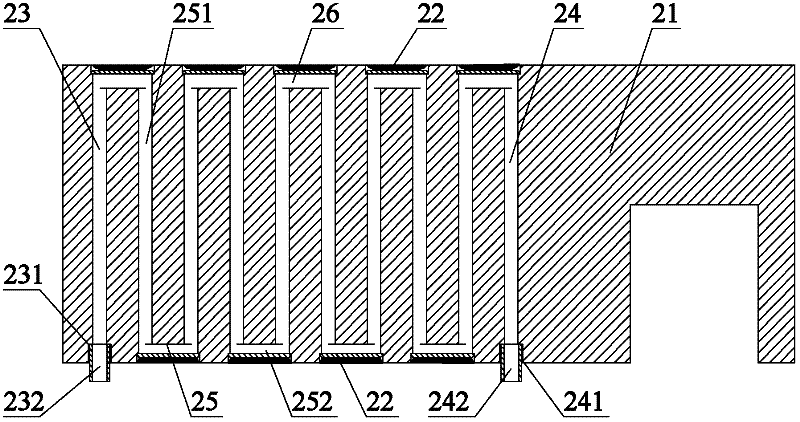

[0025] Please refer to figure 2 , figure 2 It is a schematic cross-sectional structure diagram of an electric control box cover provided by a specific embodiment of the present invention.

[0026] In a specific embodiment, the cover plate of the electric control box provided by the present invention has a plurality of through holes 23 inside, the extending direction of the through holes 23 is consistent with the width direction of the cover plate 21 of the electric control box, and each through hole 23 is along the The length direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com