Circular self-seepage recharge well head assembly

A technology of wellhead device and recharge well, which is used in water supply devices, drinking water devices, water conservancy projects, etc., can solve the problems of concrete manhole covers affecting recharge amount, large construction amount, and large consumption of building materials, etc., to prevent low water level. The effect of sewage recharge, reducing the cross-sectional area of the inlet and saving sand and gravel building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

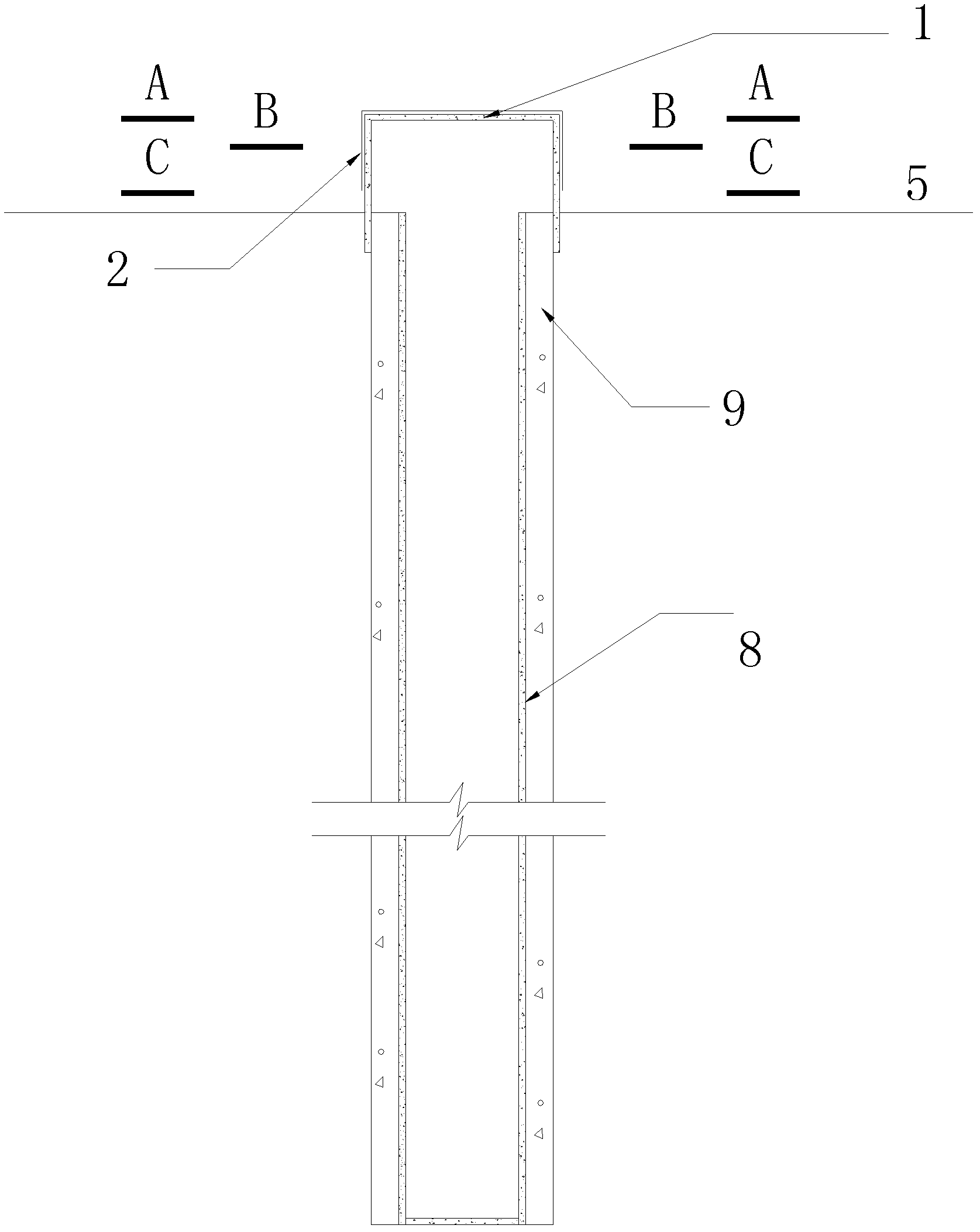

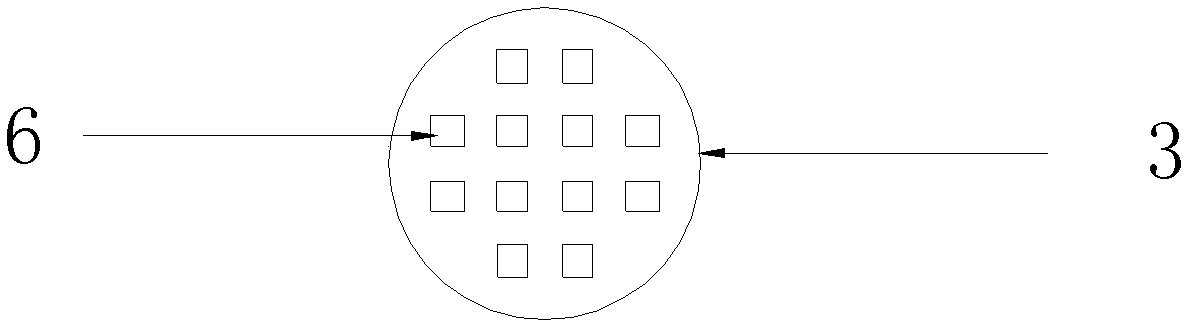

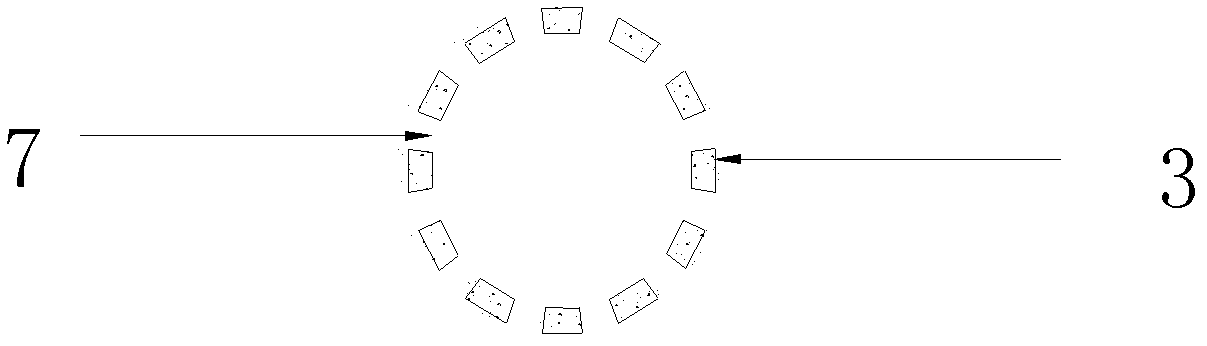

[0023] exist figure 1 Among them, this kind of circular self-seepage recharge well head device involves recharge well 8 and its wellhead. The recharge well 8 is located below the bottom of the river or the bottom of the canal. A cover is provided on the recharge well 8. The wellhead device above, the wellhead device includes a circular bottomless well cover 1, and a geotextile filter layer 2 fixedly arranged on the outside of the well cover; the well cover 1 is made of reinforced concrete or concrete or masonry material or hard chemical Any of the materials of construction. The geotextile filter layer 2 is composed of geotextiles with filter functions; the geotextiles are woven geotextiles or non-woven geotextiles. The geotextile filter layer is flatly laid on the top cover and the outside of the side wall of the manhole cover, and fixed on the manhole cover. The top cover is made into a horizontal plane or an inclined surface with a gradient of 1% in the direction of water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com