Grouting quality control method and grouting quality control device for bridge prestressed pipeline based on density parameters

A prestressed pipeline and grouting technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficulty in ensuring construction quality, hidden dangers in engineering safety, and insufficient grouting, so as to save manpower and resist interference Strong and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further explained as follows with reference to accompanying drawing in conjunction with specific embodiment:

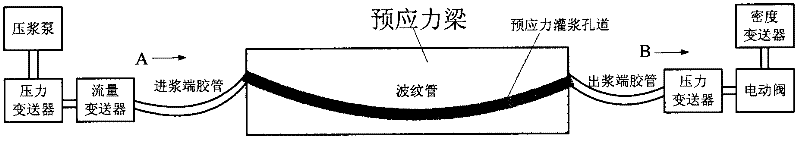

[0023] For the schematic diagram of bridge prestressed pipe grouting construction, please refer to the attached figure 1 , a quality control method for bridge prestressed pipeline grouting based on density parameters. The method is to install a flow and pressure transmitter at the slurry inlet A of the prestressed pipeline, and a pressure and density transmitter at the slurry outlet B. By measuring The water-cement specific density of the slurry is used to determine the pressure-holding time t of the screen slurry k Determine the grouting time T accordingly 0 , so as to ensure the quality of prestressed pipeline grouting.

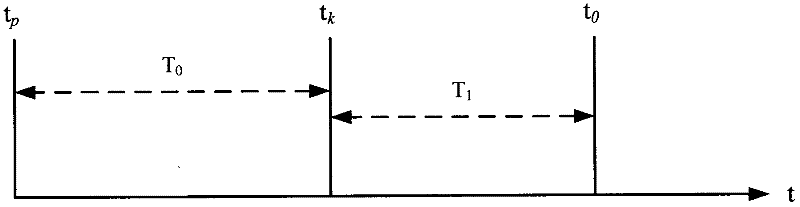

[0024] For the time sequence diagram of bridge prestressed pipeline grouting and screen grouting construction status, please refer to the attached figure 2 , t in the figure p is the start time of grouting, at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com