Modified ether polycarboxylic acid water reducing agent and preparation method thereof

A technology of ether polycarboxylic acid and water reducing agent, which is applied in the field of concrete admixtures, can solve the problems of difficult molecular weight control, large slump loss, low concrete water reduction rate, etc., and achieves high product stability and improved adaptability. The effect of high performance, double bond retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The modified ether polycarboxylate water reducer described in the present invention has the following monomer composition and proportioning ratio:

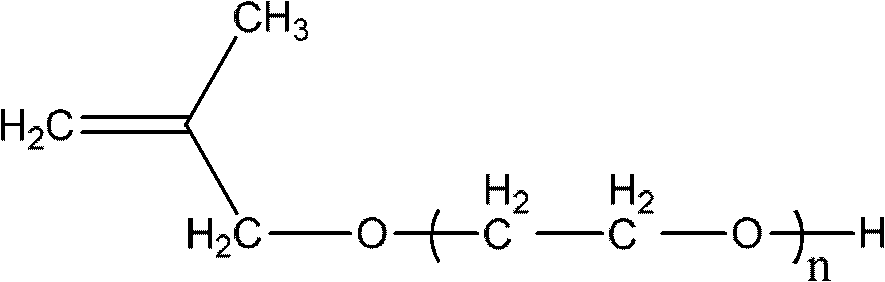

[0037] Monomer A: methallyl polyoxyethylene ether (TPEG), molecular weight 2400, accounting for 95% of the total monomer weight;

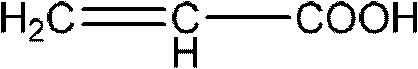

[0038] Monomer B: acrylic acid (AA), accounting for 4% of the total monomer weight;

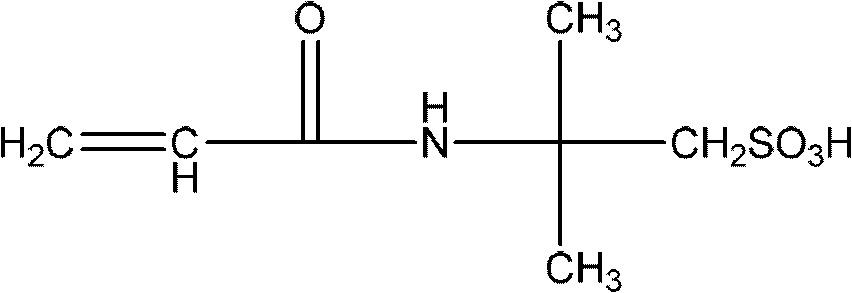

[0039] Monomer C: 2-acrylamido-2-methylpropanesulfonic acid (AMPS), accounting for 1% of the total weight of the monomers.

[0040] The preparation method of above-mentioned modified ether polycarboxylate water reducer can be expressed as follows:

[0041] Add 95g of methallyl polyoxyethylene ether monomer into the reactor. When the temperature rises to 30-50°C, add 95g of deionized water to dissolve it; ℃, while adding dropwise a mixed aqueous solution made of 4g of acrylic acid monomer, 1g of 2-acrylamido-2-methylpropanesulfonic acid monomer, and 6g of deionized water, 0.1g of mercaptopropionic acid, and 20...

Embodiment 2

[0043] The modified ether polycarboxylate water reducer described in the present invention has the following monomer composition and proportioning ratio:

[0044] Monomer A: methallyl polyoxyethylene ether (TPEG), molecular weight 2400, accounting for 65% of the total monomer weight;

[0045] Monomer B: acrylic acid (AA), accounting for 30% of the total monomer weight;

[0046] Monomer C: 2-acrylamido-2-methylpropanesulfonic acid (AMPS), accounting for 5% of the total weight of the monomers.

[0047] The preparation method of above-mentioned modified ether polycarboxylate water reducer can be expressed as follows:

[0048] Add 65g of methallyl polyoxyethylene ether monomer into the reactor. When the temperature rises to 30-50°C, add 30g of deionized water to dissolve it; ℃, while adding dropwise a mixed aqueous solution made of 30g acrylic acid monomer, 5g 2-acrylamido-2-methylpropanesulfonic acid monomer and 24g deionized water, 2g mercaptoacetic acid, 40g 10% ammonium pers...

Embodiment 3

[0050] The modified ether polycarboxylate water reducer described in the present invention has the following monomer composition and proportioning ratio:

[0051] Monomer A: methallyl polyoxyethylene ether (TPEG), molecular weight 2400, accounting for 50% of the total monomer weight;

[0052] Monomer B: acrylic acid (AA), accounting for 40% of the total monomer weight;

[0053] Monomer C: 2-acrylamido-2-methylpropanesulfonic acid (AMPS), accounting for 10% of the total weight of the monomers.

[0054] The preparation method of above-mentioned modified ether polycarboxylate water reducer can be expressed as follows:

[0055]Add 50g of methallyl polyoxyethylene ether monomer into the reactor. When the temperature rises to 30-50°C, add 15g of deionized water to dissolve it; ℃, while adding dropwise the mixed aqueous solution made of 40g acrylic acid monomer, 10g 2-acrylamido-2-methylpropanesulfonic acid monomer and 20g deionized water, 4g mercaptoacetic acid, 80g 10% potassium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com