Frame assembly for foldable electric vehicle

An electric vehicle and assembly technology, applied in the field of frame assembly, can solve the problems of slow folding speed, insufficient folding, complicated locking method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

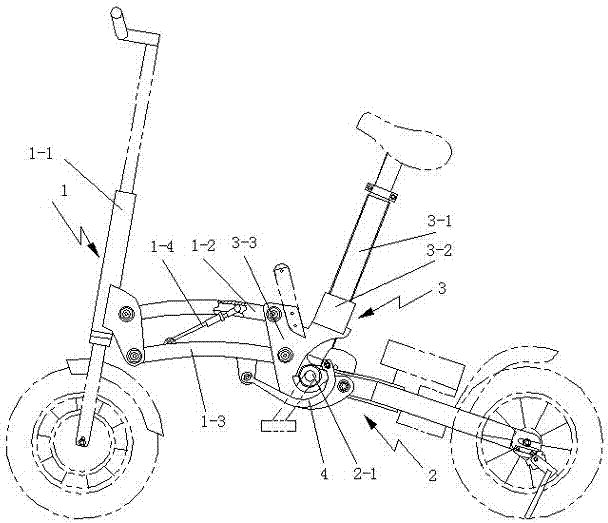

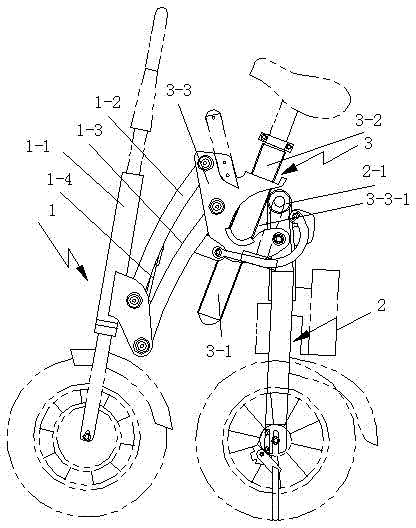

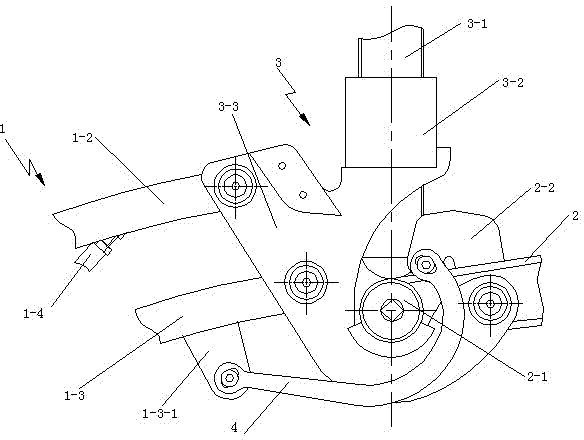

[0018] see figure 1 , 2 , 3, 4, 5, 6, and 7 show a vehicle frame assembly of a folding electric vehicle, including a front tripod assembly 1, a rear tripod assembly 2 and a seat assembly 3, and the front tripod assembly 1 has a head frame 1-1, an upper beam 1-2, a lower beam 1-3 and a strut 1-4, wherein one end of the upper beam 1-2 and the lower beam 1-3 are hinged on the head frame 1-1 , the other end is hinged on the front end of the seat assembly 3, one end of the strut 1-4 is hinged on the lower beam 1-3, the other end is slidingly connected to the upper beam 1-3, and the lower beam 1-3 is also hinged with a connecting rod 4 , the other end of the connecting rod 4 is hinged on the rear triangle frame assembly 2, and the rear triangle assembly 2 is hinged on the rear end of the vehicle seat assembly 3, and the vehicle seat assembly 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com