Side connecting component for automobile floor

A side connection and floor technology, which is applied in the field of auto parts, can solve problems such as affecting the rigidity, fatigue durability of the connection between the floor and the seat, and affecting the local mode of the seat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

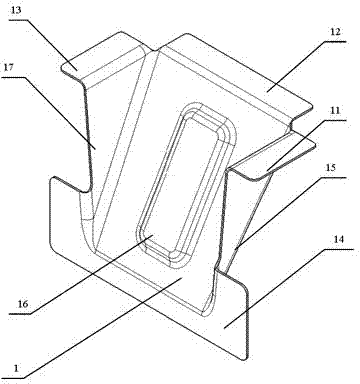

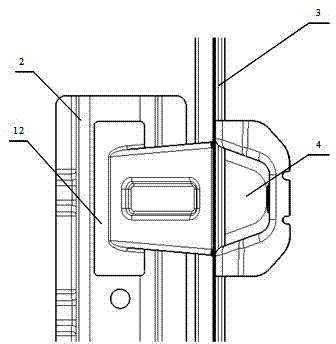

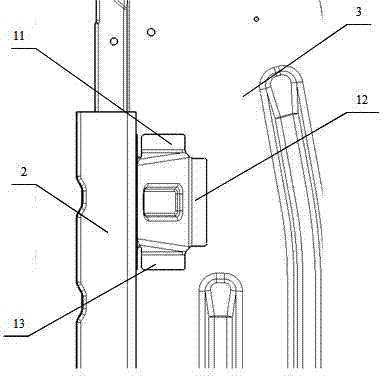

[0012] see figure 1 Shown is a car floor side connector, the main body is an integral stamping part, the main plane 1 of the main body is rectangular, the upper part of the main plane is bent backward and right to form the upper connecting part 12; the right side of the main plane is vertically connected with a top The right triangular support plate 15 with the angle downwards, the top of the right triangular support plate bends to the right to form the right connecting portion 11; The upper part is bent to the left to form the left connecting part 13; the lower connecting part 14 of a "concave" shape is connected with the bottom of the right triangular support plate and the bottom of the left triangular support plate and the lower edge of the main plane; the upper connecting part 12, the right The connecting part 11, the left connecting part 13 and the lower connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com