Multifunctional machine tool

A multifunctional machine tool and column technology, applied in the mechanical field, can solve the problems of wasting time and increasing costs, and achieve the effects of simple and rapid conversion, strong adaptability and wide processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

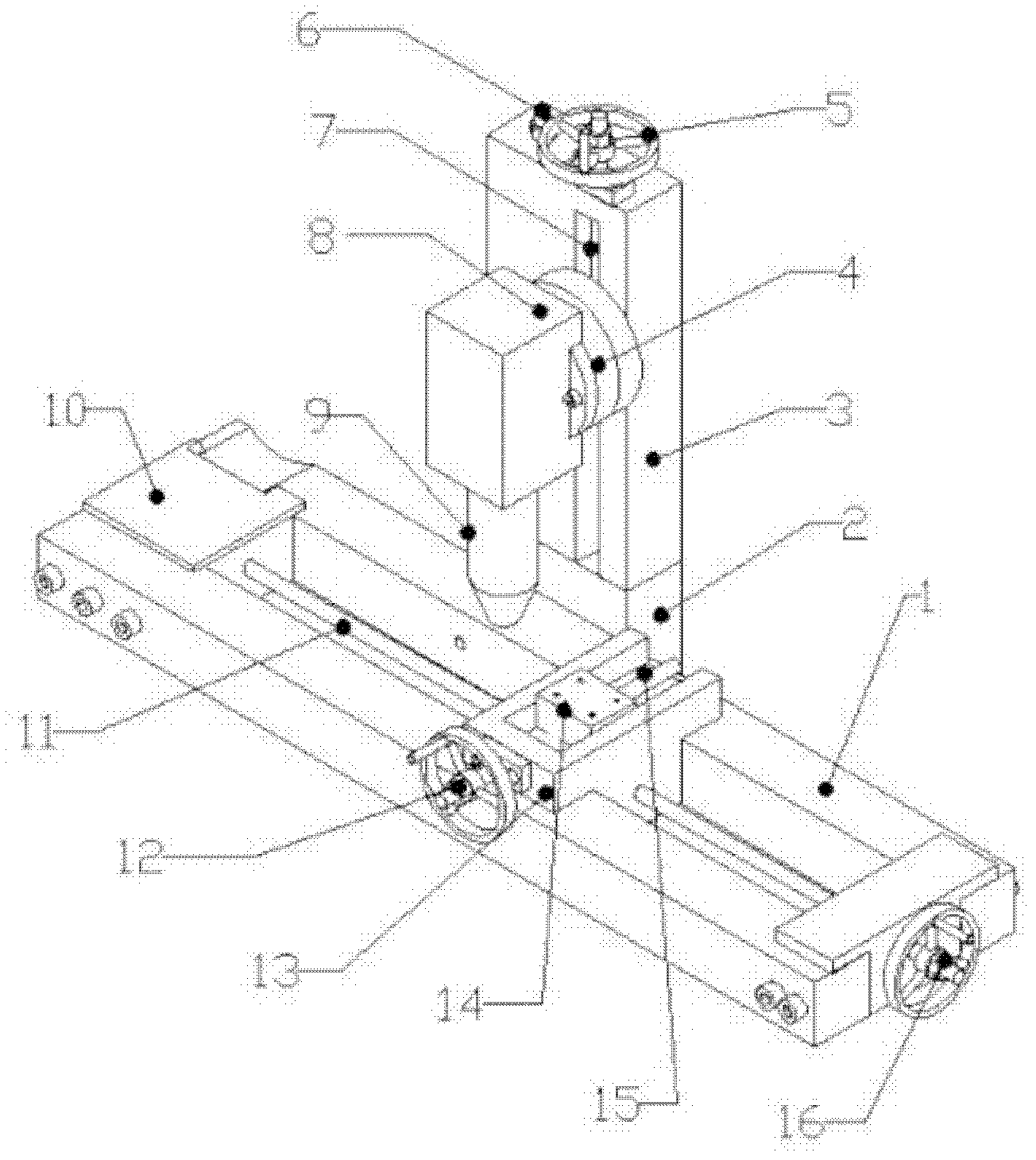

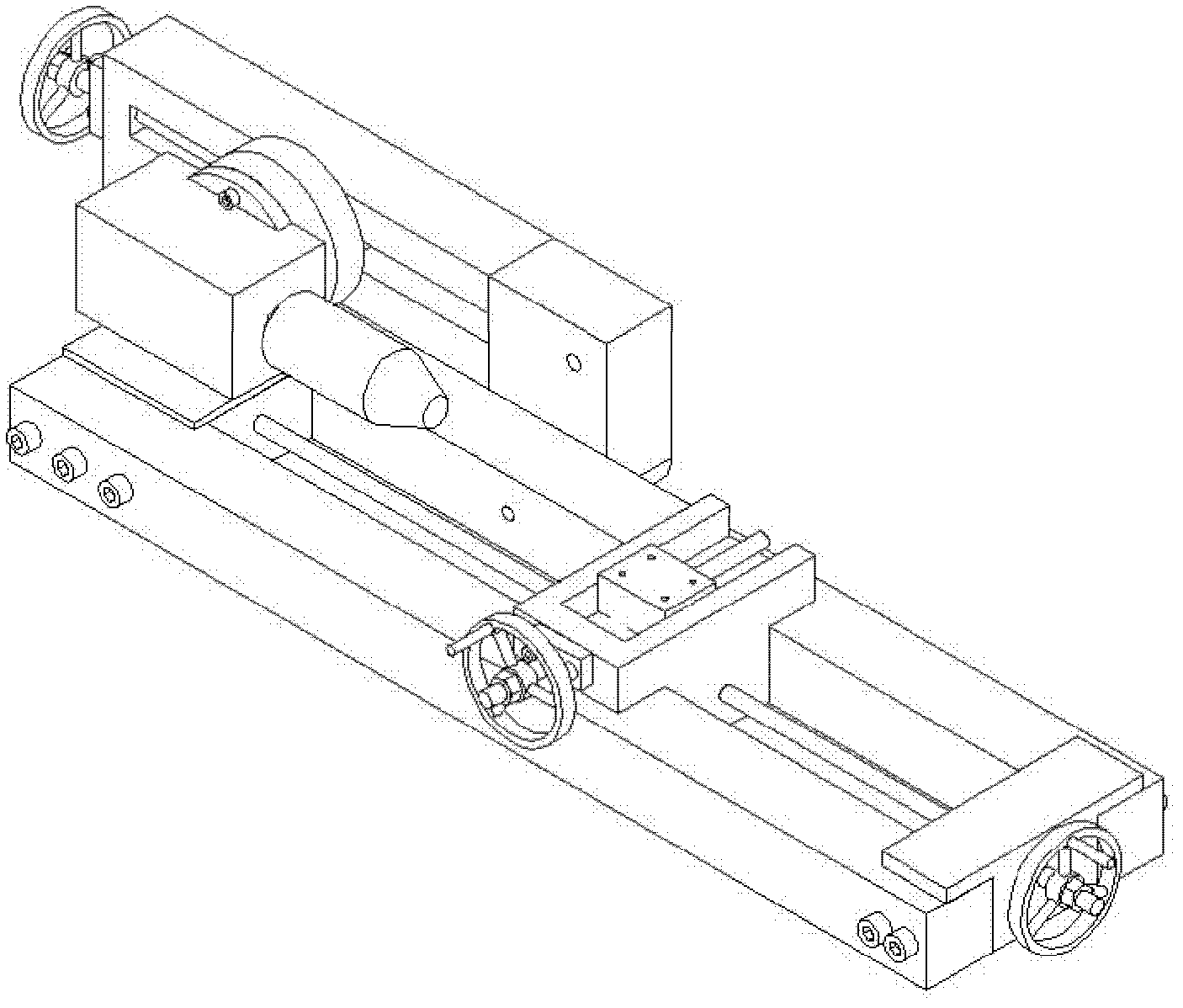

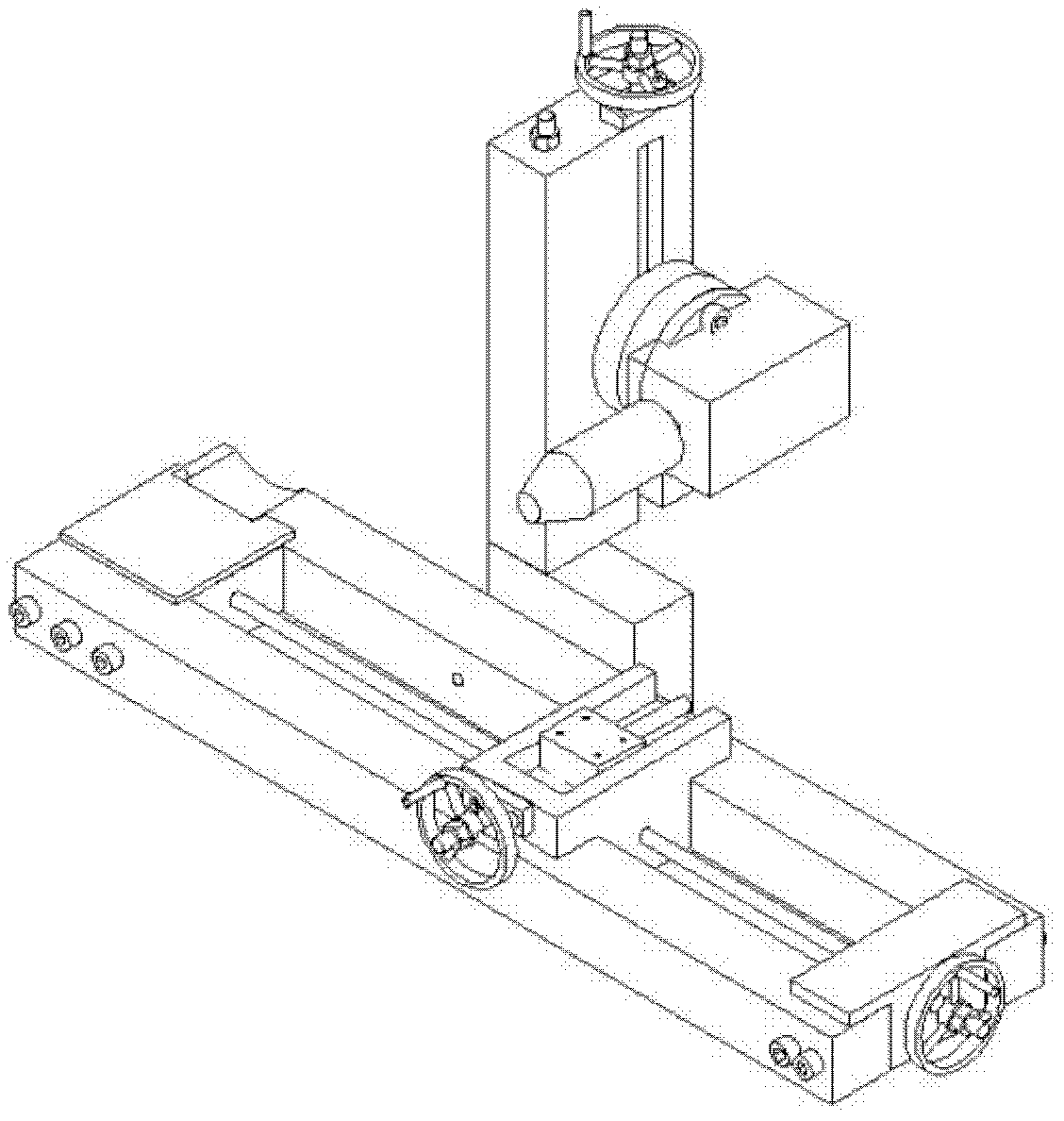

[0014] Such as Figure 1 to Figure 3 shown. A multifunctional machine tool, comprising 1 guide rail, 2 column bases, 3 columns, 4 spindle seats, 5 hand wheels 1, 6 column connecting bolts, 7 column screw screws, 8 spindle boxes, 9 spindle chucks, 10 headstocks, 11 main screw, 12 hand wheel II, 13 longitudinal slide plate, 14 transverse slide plate, 15 transverse screw rod, 16 handwheel III, 17 column bolt I, 18 column bolt II, which is characterized in that the headstock 8 is installed on the main shaft On the seat 4, loosen the bolt on the headstock 8 to rotate the headstock 8 at a certain angle, and fix it with bolts, shake the handwheel I to make the headstock 4 drive the headstock 8 to move up and down along the column, shake the handwheel II, and pass the horizontal wire The bar 15 drives the horizontal sliding plate 14 to move laterally, shakes the hand wheel III, drives the longitudinal sliding plate 13 to move along the guide rail 1 through the main screw 11, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com