Semiconductor component overturning device and test equipment thereof

A test equipment, semiconductor technology, applied in semiconductor/solid-state device manufacturing, electrical components, conveyor objects, etc., can solve the problem that semiconductor components cannot be picked and placed at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

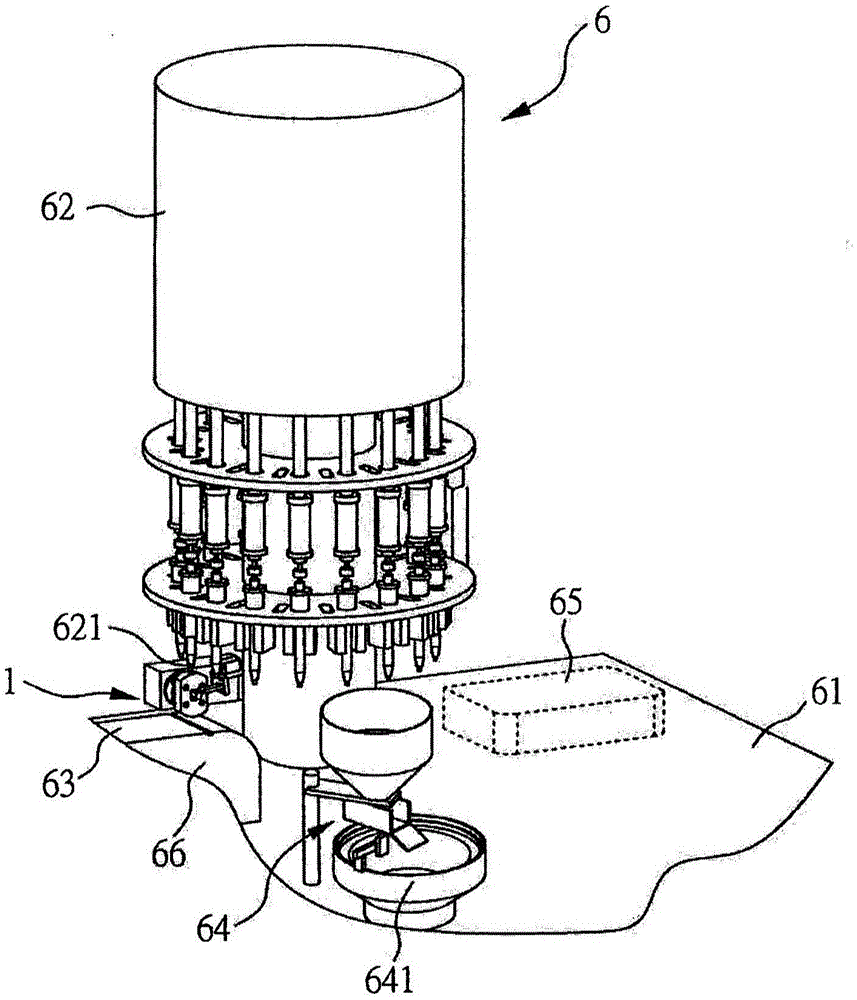

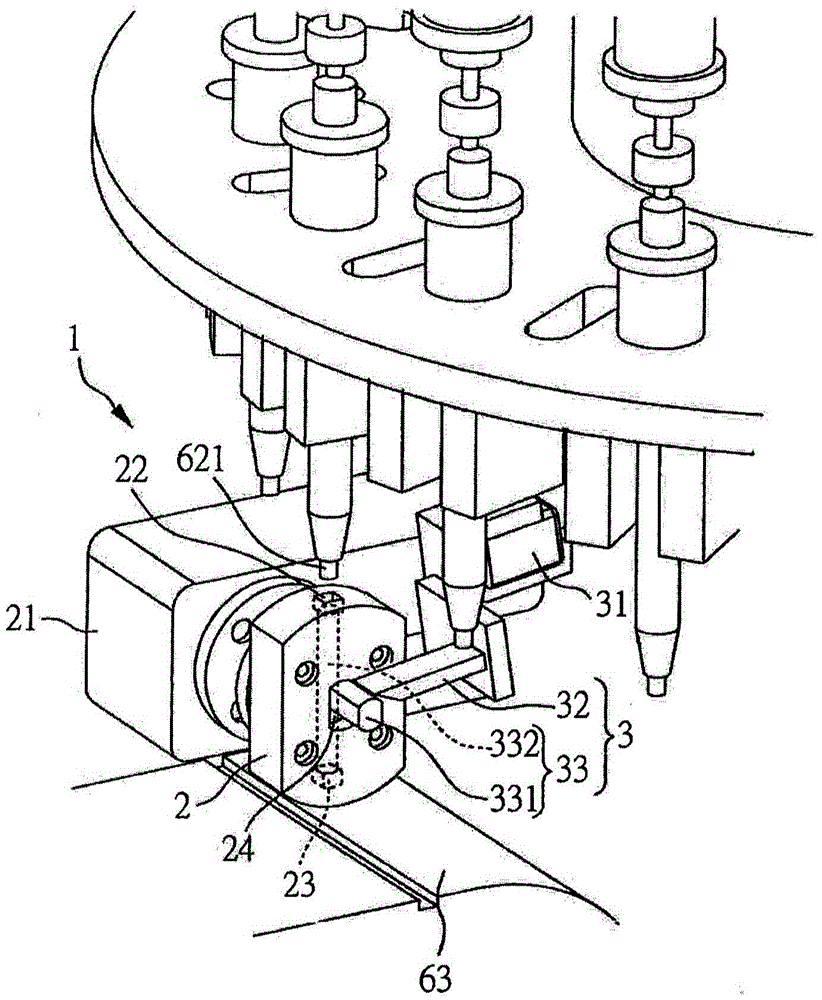

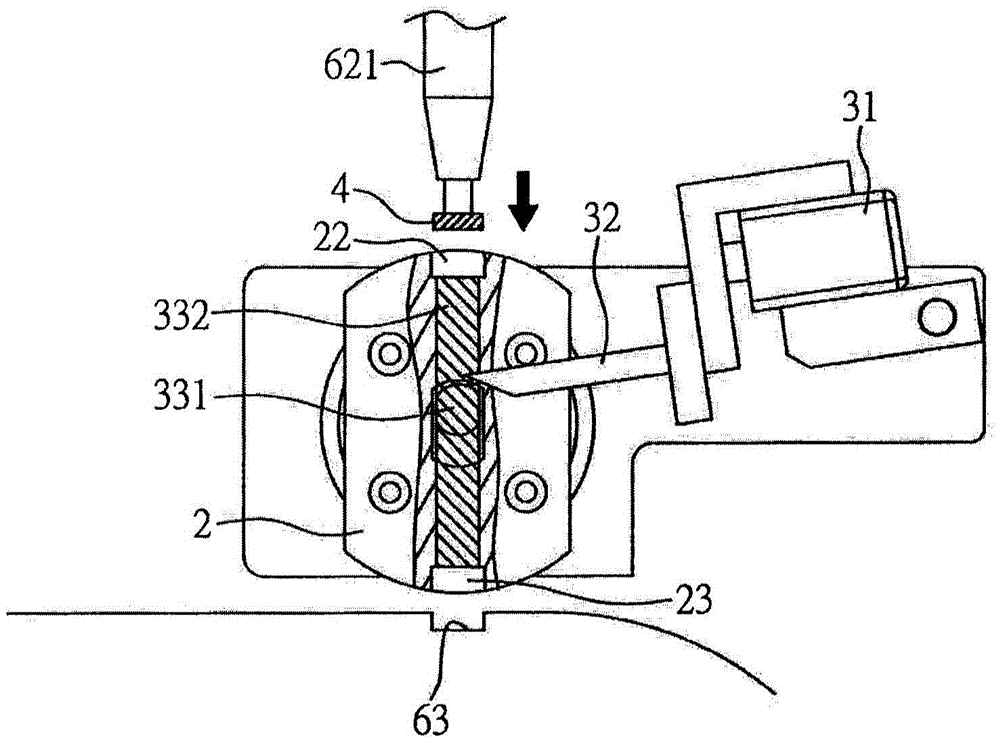

[0023] see figure 1 and figure 2 , is a perspective view of the semiconductor element inversion testing equipment and a perspective view of the semiconductor element inversion device according to the first embodiment of the present invention. Such as figure 1 As shown, first viewed from the whole, the semiconductor device inversion testing equipment of the present invention includes a semiconductor device inversion device 1 and a sorting machine 6 . In this embodiment, the sorting machine 6 includes a turret 62 arranged on a working table 61 and a feeding area 64, a testing area 65 and a discharging area 66 arranged around the turret 62, wherein The material area 64 can be a vibrating plate (Bowl feeder) 641 , and the output area 66 includes a packaging roll 63 . The turret 62 includes a plurality of suction heads 621 arranged at intervals at an angle, one end of which sucks a semiconductor element 4 from the feed area 64 and rotates to the test area 65, and then turns t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com