OLED flexible printed circuit board vacuum adsorption device

A flexible circuit board and vacuum adsorption technology, applied in the field of OLED display, can solve problems such as complicated disassembly and replacement procedures, achieve the effects of convenient and fast conversion, reduce equipment costs, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

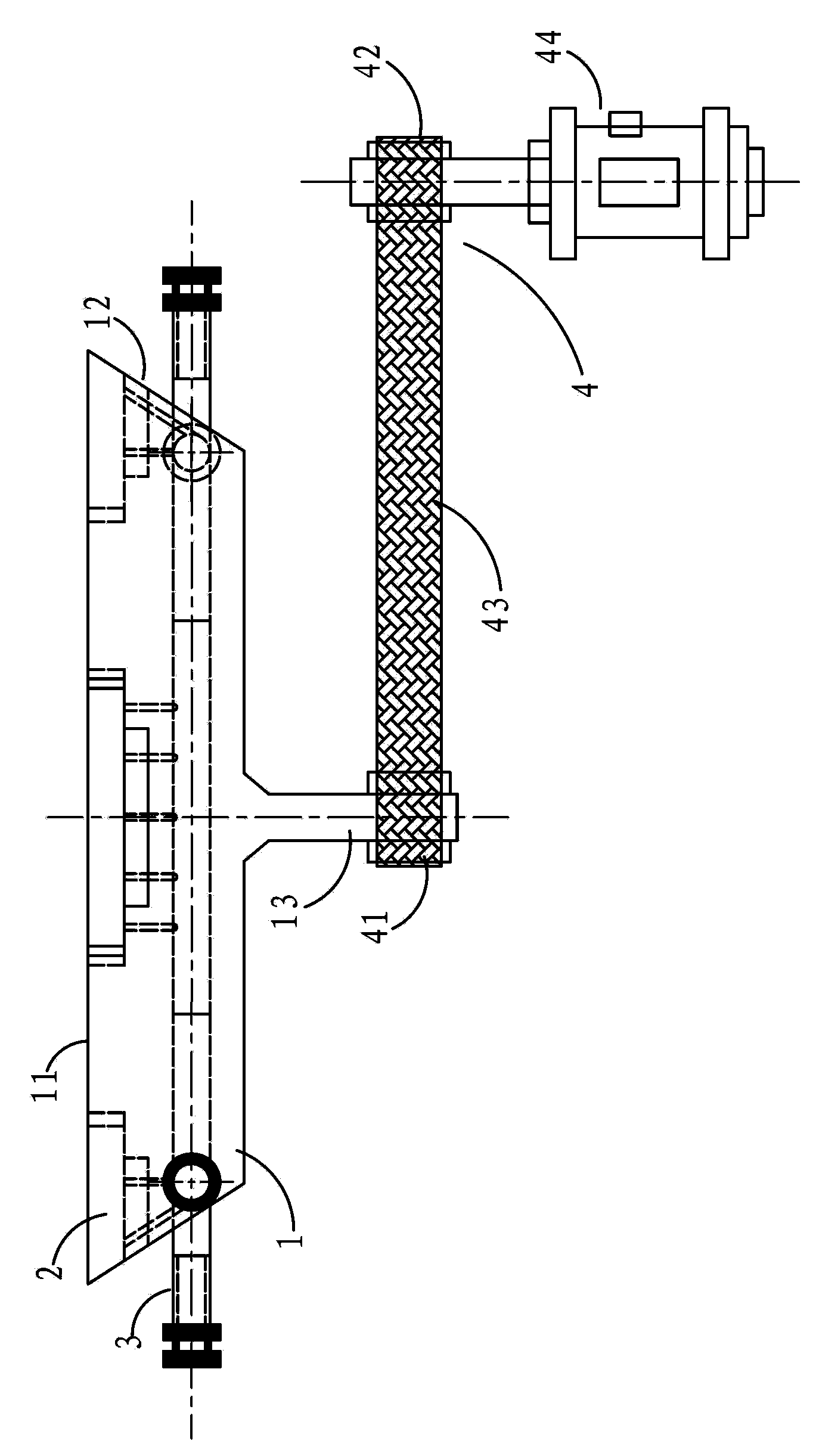

[0022] Such as figure 1 As shown, a vacuum adsorption device for an OLED flexible circuit board includes a conical platform 1 and a vacuum tube 3, which is characterized in that the conical platform 1 contains at least two grooves 2 of different shapes, and the vacuum tube 3 and the groove 2 connected.

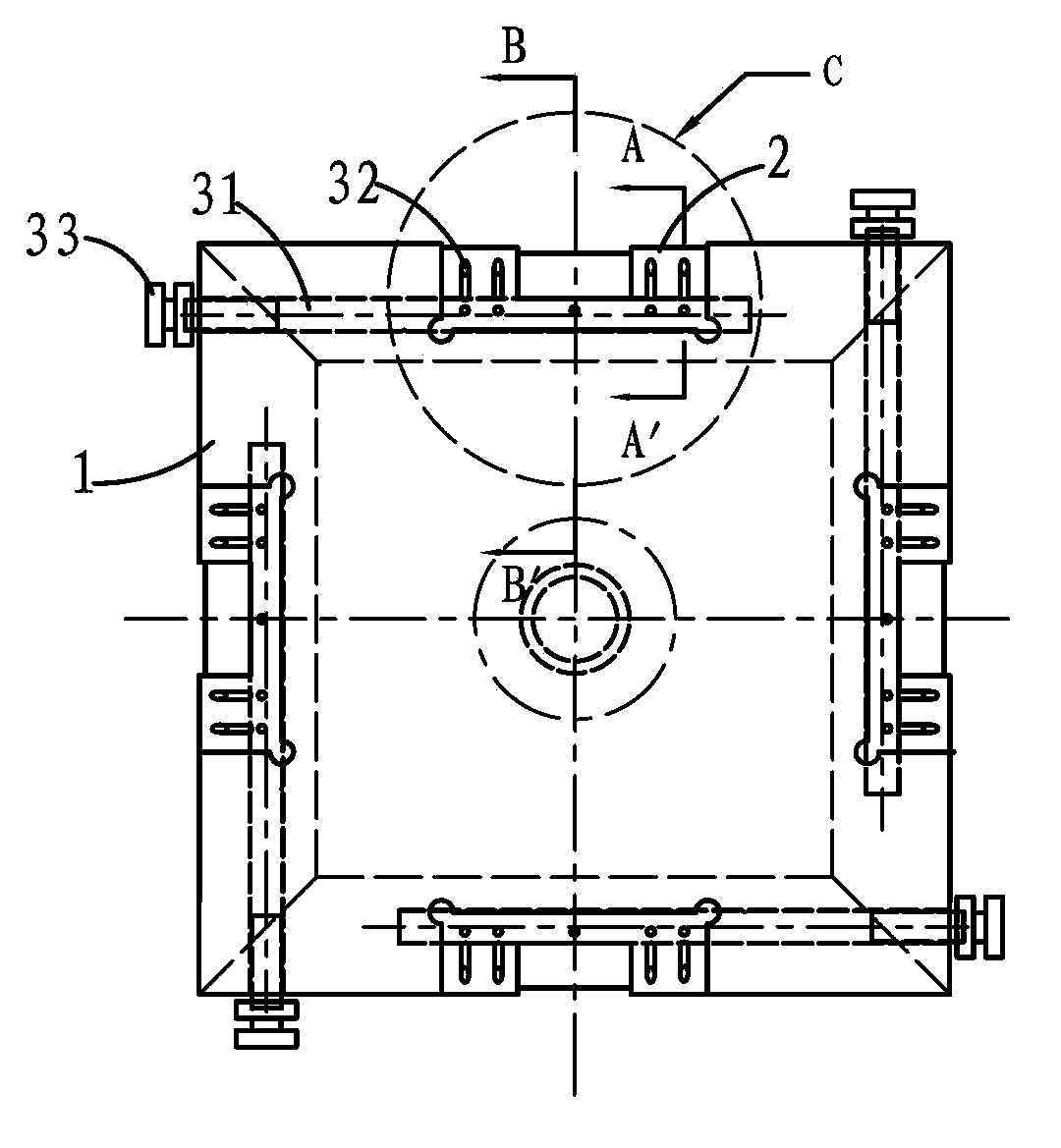

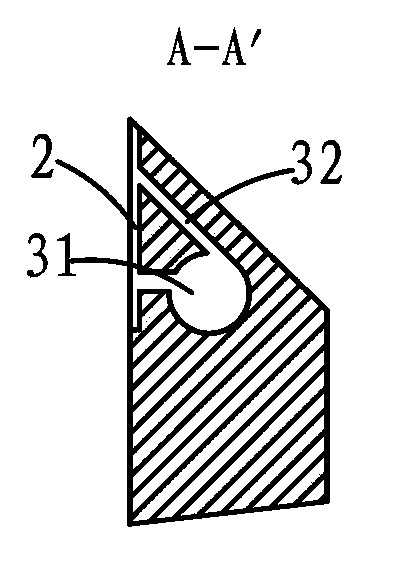

[0023] Such as figure 2 As shown, the above-mentioned conical platform 1 is a square, including an upper plane 11 and a conical slope 12, and the grooves 2 are arranged on each edge of the upper plane 11 of the conical platform 1. The shapes of the grooves 2 are different, respectively Corresponding to a type of OLED flexible circuit board, the conical slope of the conical pedestal is provided for placing a sensor of the vacuum adsorption device of this embodiment.

[0024] Through the above description, those skilled in the art should unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com