One-key automatic steaming cabinet control system

A technology of control system and rice cooker, applied in the direction of electrical program control, program control in sequence/logic controller, etc., can solve the problems of short circuit, unacceptable, large use current, etc., to achieve accurate operation time and easy maintenance , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

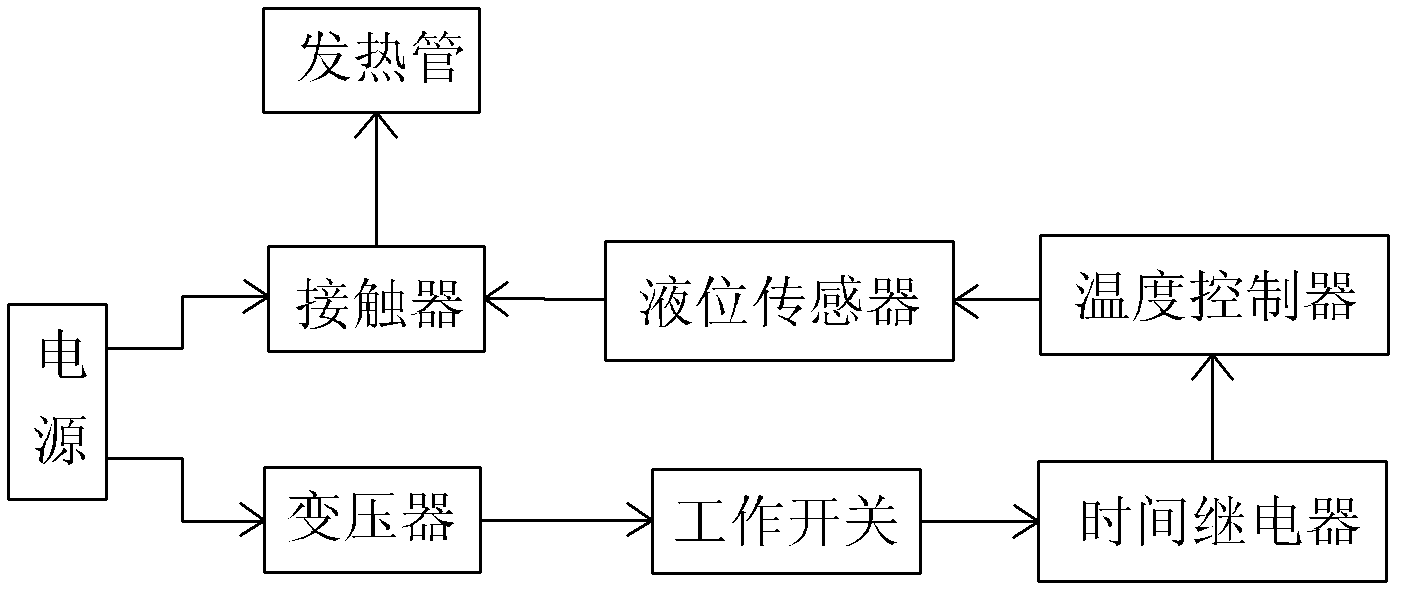

[0019] The power supply is connected to the heating tube through the main contact of the contactor, and the transformer, time relay, temperature controller and button switch are set. The primary side of the transformer is connected to the power supply, and the secondary side of the transformer is connected to the input terminal of the time relay through a series button switch. The time relay The output end of the temperature controller is connected to the control end of the contactor through the temperature controller connected in series, and the signal input end of the temperature controller is connected to the temperature sensor arranged in the rice steaming cabinet.

[0020] The high voltage power is converted into low voltage control power through a transformer when connected to the power supply. By simply closing the button switch, the output voltage of the time relay controls the pull-in of the contactor, the heating tube works to steam rice, and then the time relay accur...

Embodiment 2

[0023] Such as figure 1 , figure 2 As shown, the power supply L1-L3 is connected to the input terminal G1-G3 of the heating tube through the main contact of the contactor U1, the primary side of the transformer U2 is connected to the power supply, and the secondary side of the transformer U2 is connected to the input of the time relay U3 through the series button switch SB1 The output terminal of the time relay U3 is connected to the control terminal of the contactor U1 through the temperature controller U4 connected in series, and the signal input terminal of the temperature controller U4 is connected to the temperature sensor ST1. The control end of the contactor U1 is connected to a liquid level sensor ST2, and the liquid level sensor ST2 is connected in series with the temperature controller U4. The liquid level switch controls the suction of the contactor of the control line lower than the water level of the heating pipe. After water shortage, the liquid level sensor d...

Embodiment 3

[0025] On the basis of Embodiment 2, the control terminal of the contactor U1 is set to connect to the working status indicator, one input terminal of the working status indicator is connected to the control terminal A1 pin of the contactor U1, and the other input terminal is connected to the secondary side of the transformer U2 the 0V pin. When the control terminal of the contactor U1 is at the working voltage, the indicator light is on, which is used to indicate whether the contactor U1 is working, that is, whether the heating tube L1 is energized and working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com