Orthogonal field calibration device for three-component magnetic probe and calibration method thereof

A field calibration, three-component magnetic technology, applied in the direction of geophysical measurement, instruments, etc., can solve the problems of difficult to meet the measurement requirements, unattractive application value, unable to meet the requirements of actual vector measurement, etc., to reduce the measurement cost, The effect of convenient field work and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

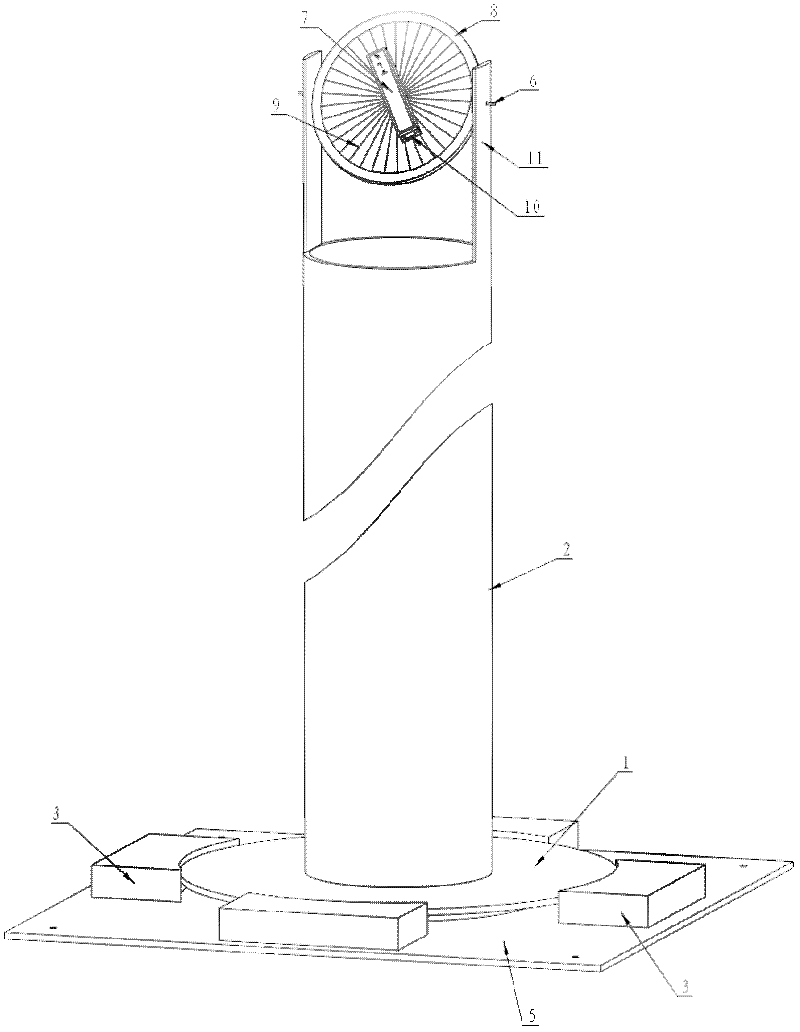

[0043]The field calibration device for the orthogonality of the three-component magnetic probe is composed of a thrust bearing 4 and more than three limit blocks 3 on the base 5, the limit blocks 3 limit the rotation platform 1, and the thrust bearing 4 is equipped with a rotating The platform 1 and the cylinder 2 are fixed on the rotating platform 1. The upper part of the cylinder 2 is an ear-shaped convex strip 11. The diameter of the flat shaft 6 coincides with the diameter of the disc 8 and is fixed on the disc 8. The two ends of the horizontal shaft 6 are respectively Through the two ear-shaped protrusions 11, the disc 8 is suspended between the two ear-shaped protrusions 11, the disc 8 rotates around the horizontal axis 6, the disc 8 is equipped with an angle disc 9, and the three-component probe 7 is passed through a screw or The rotating shaft is fixed on the dial 9, and one end of the three-component probe 7 is equipped with a connector 10 to form it.

[0044] The fie...

Embodiment 2

[0055] The field calibration device for the orthogonality of the three-component magnetic probe is composed of a thrust bearing 4 and more than three limit blocks 3 on the base 5, the limit blocks 3 limit the rotation platform 1, and the thrust bearing 4 is equipped with a rotating The platform 1 and the cylinder 2 are fixed on the rotating platform 1. The upper part of the cylinder 2 is an ear-shaped convex strip 11. The diameter of the flat shaft 6 coincides with the diameter of the disc 8 and is fixed on the disc 8. The two ends of the horizontal shaft 6 are respectively Through the two ear-shaped protrusions 11, the disc 8 is suspended between the two ear-shaped protrusions 11, the disc 8 rotates around the horizontal axis 6, the disc 8 is equipped with an angle disc 9, and the three-component probe 7 is passed through a screw or The rotating shaft is fixed on the dial 9, and one end of the three-component probe 7 is equipped with a connector 10 to form it.

[0056] The fi...

Embodiment 3

[0067] The field calibration device for the orthogonality of the three-component magnetic probe is composed of a thrust bearing 4 and more than three limit blocks 3 on the base 5, the limit blocks 3 limit the rotation platform 1, and the thrust bearing 4 is equipped with a rotating The platform 1 and the cylinder 2 are fixed on the rotating platform 1. The upper part of the cylinder 2 is an ear-shaped convex strip 11. The diameter of the flat shaft 6 coincides with the diameter of the disc 8 and is fixed on the disc 8. The two ends of the horizontal shaft 6 are respectively Through the two ear-shaped protrusions 11, the disc 8 is suspended between the two ear-shaped protrusions 11, the disc 8 rotates around the horizontal axis 6, the disc 8 is equipped with an angle disc 9, and the three-component probe 7 is passed through a screw or The rotating shaft is fixed on the dial 9, and one end of the three-component probe 7 is equipped with a connector 10 to form it.

[0068] The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com