Multifunctional brake disc of electric vehicle

A multi-functional, electric vehicle technology, applied in the direction of brake drums, bicycle accessories, brake types, etc., can solve the problems of not achieving the ideal effect, complicated manufacturing, affecting the braking effect, etc., and achieve a good locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

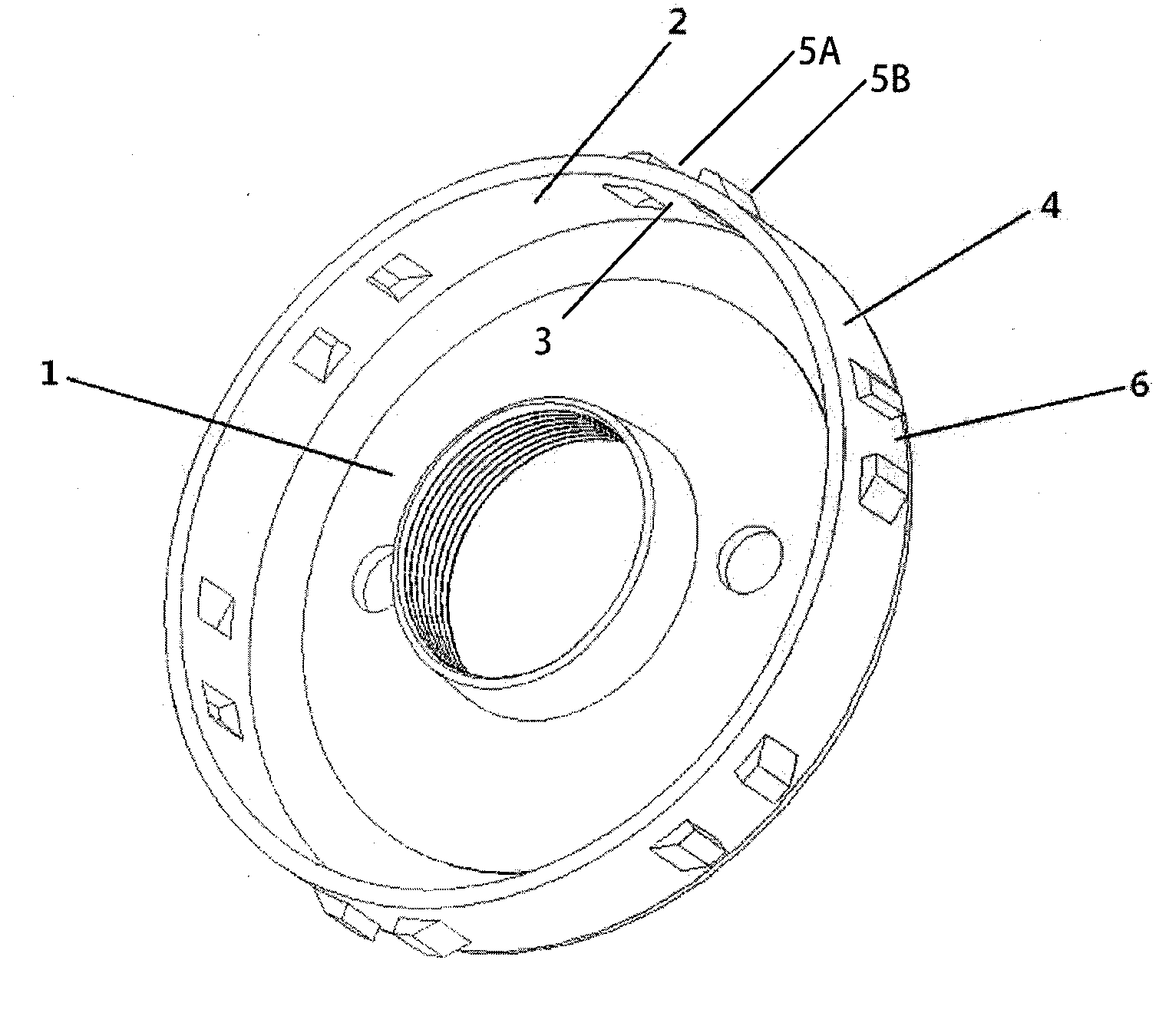

[0014] A multifunctional brake disc of an electric vehicle is composed of a brake disc 1, a notch 3 is opened on the inner side 2 of the brake disc circumference, and a bump 5 is provided at the corresponding position between the outer circumference 4 of the brake disc 1 and the notch 3, and the bump 5- Between A and 5-B is a notch shape, and the notch shape is provided with a locking hole 6 that matches the dead bolt (not noted in this figure), and the locking hole 6 is matched with the dead bolt (not noted in this figure).

[0015] The first function is to set the notch 3 on the inner side of the brake disc 1. The function is to make the brake block (not noted in this figure) rub against the inner side 2 of the brake disc 1 for continuous use, because there are several notches 3 on the inner side 2 of the brake disc 1. , the brake block (not noted in this figure) and the brake disc 1 will have continuous friction around the inner side of the brake disc to form continuous fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com