Waste heat fuel-saving device of diesel internal combustion engine

A diesel internal combustion engine, permanent magnet technology, applied in fuel heat treatment devices, internal combustion piston engines, combustion engines, etc., can solve problems such as difficulty in starting, insufficient combustion, waste of resources, etc., to curb black smoke emissions, save fuel, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

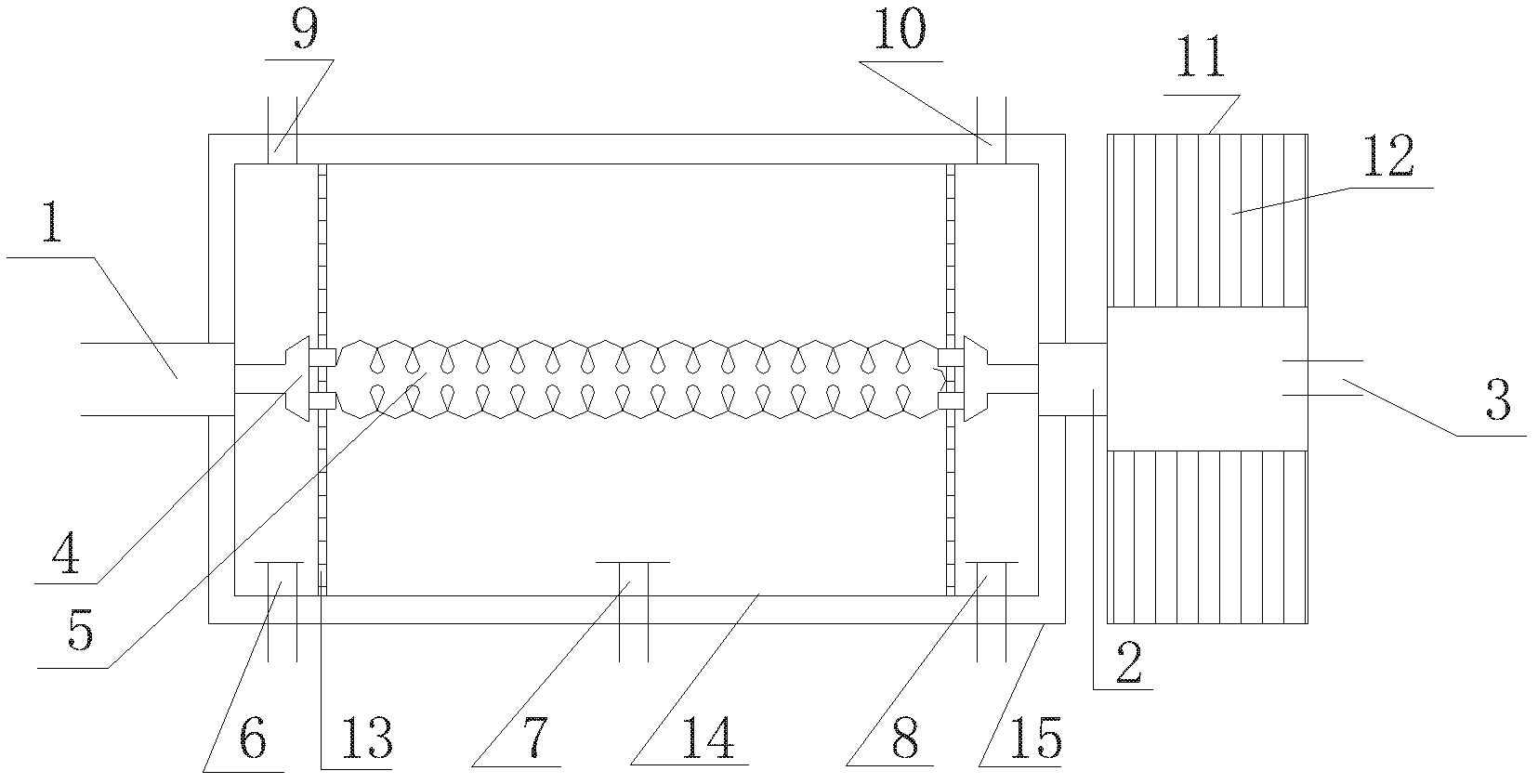

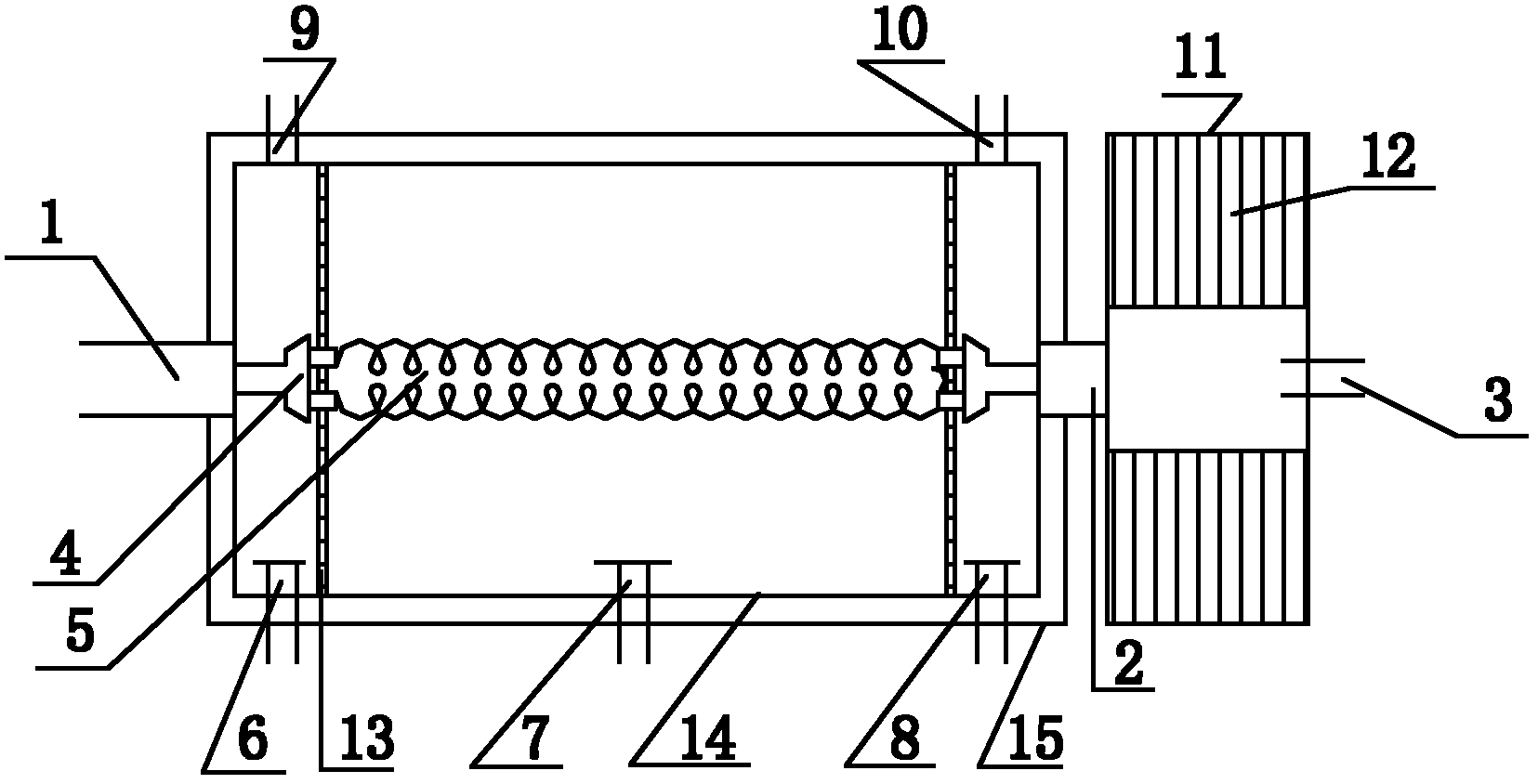

[0018] Such as figure 1 As shown, the diesel internal combustion engine waste heat permanent magnet fuel-saving device of the present invention includes a control circuit, a heating device and a permanent magnet assembly 12, wherein,

[0019] The control circuit is a central processing unit, which is mainly used to receive, process and control the detection information of temperature and pressure involved in the present invention and the execution of relevant valve actions.

[0020] The heat supply device is mainly used to heat the diesel oil flowing through the present invention before entering the cylinder of the diesel internal combustion engine, so that its viscosity reaches the optimum value. The heat supply device is composed of a shell 14 and internal components, and the shell 14 is a closed hollow Cylinder, the housing is made of meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com