Method for preparing sol for stabilizing properties of anti-reflection film of solar glass

A technology of solar glass and anti-reflection film, applied in optics, instruments, optical components, etc., can solve the problems of reducing the reaction speed of sol-gel and poor molecular structure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

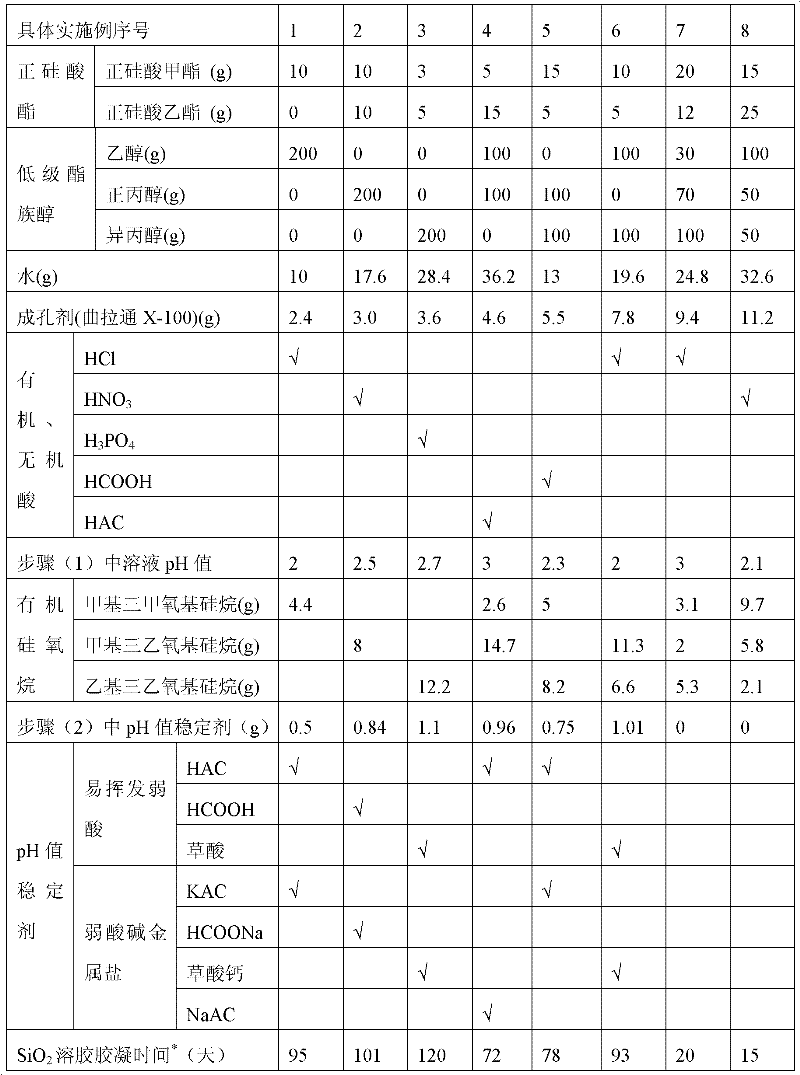

[0018] The present invention is further described by examples below.

[0019] The preparation method for preparing the solar glass anti-reflection film sol with stable properties provided by the present invention comprises the following steps:

[0020] (1) Under the stirring condition of 300r / min, add orthosilicate into the lower aliphatic alcohol solvent, mix well; then add water, then add pore-forming agent Triton X-100, mix and add organic acid Or inorganic acid to adjust the pH value of the solution between 2 and 3, react at 60°C for 4h; then add alkylsiloxane, mix well and continue to react at 60°C for 2h to obtain SiO for anti-reflective coating 2 Polymer sol; wherein, orthosilicate: lower aliphatic alcohol solvent: water: triton X-100: the weight percent of alkylsiloxane is: 1~20:50~85:10~20:1~ 5:2~10;

[0021] (2) To the above SiO 2 Add a pH stabilizer with a pH value of 6.8 to 7.8 in the polymer sol, SiO 2 Polymer sol: the weight percentage of the pH value stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com