Automatic control method of Rp value of alumina digestion outlet in the Bayer process

An alumina and Bayer technology, applied in the field of control, can solve the problems of long dissolution process, lag in Rp value, difficult to clean, etc., and achieve the effects of low operation and maintenance costs, suppression of control lag, and reliable measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

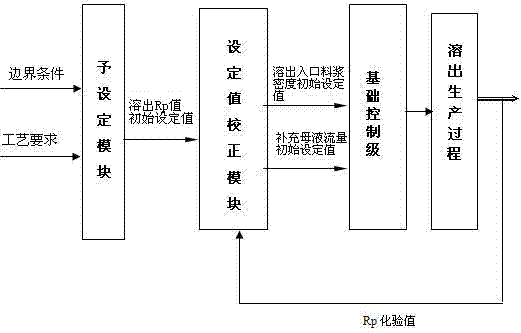

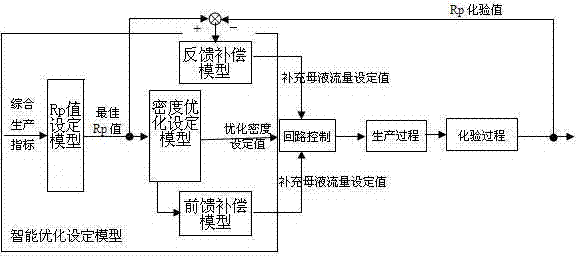

[0018] An automatic control method for the Rp value of the dissolution outlet of Bayer process alumina, adopting the intelligent optimization setting technology aimed at finding the best Rp value of the dissolution outlet, according to the Rp target value of the dissolution outlet, the laboratory Rp value of the dissolution outlet, and the dissolution inlet The alumina concentration of the slurry, the solid content of the grinding outlet, the concentration and temperature of the supplementary mother liquor, and the ore composition value are intelligently set by the computer. The inlet slurry density value of the dissolution system; The cascade control system composed of the slurry density at the inlet of the dissolution system as the control variable of the cascade control system and the supplementary mother liquor flow rate at the inlet of the dissolution system as the auxiliary control variable of the cascade control system adjusts the flow of the mother liquor at the inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com