Transmission electric chuck for planetary gear driven by hydraulic motor

A technology of planetary gears and hydraulic motors, applied in the direction of chucks, etc., can solve problems such as easy overload, easy overload accidents, low transmission efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

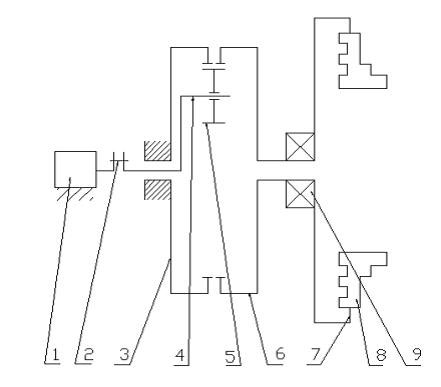

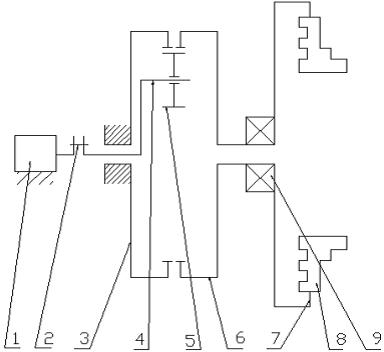

[0008] In the figure, the hydraulic motor-driven planetary gear electric chuck includes hydraulic motor 1, coupling 2, fixed internal gear 3, planetary gear carrier 4, planetary gear 5, passive internal gear 6, helical gear 7, chuck Catch 8, bearing 9, described fixed internal gear 3 and passive internal gear 6 are provided with corresponding addendum circle, described fixed internal gear 3 and passive internal gear 6 are mutually corresponding displacement; And fixed internal gear 3 and passive internal gear The internal gear 6 is provided with a number of teeth with a difference of 2, and the planetary gear 5 is fixedly installed on the planetary gear carrier 4 through the fixed internal gear 3, and the planetary gear 5 is meshed with the fixed internal gear 3. The hydraulic motor is connected with the planetary gear carrier 4 through the coupling 2, and the passive internal gear 6 is fixedly installed with the helical gear 7 through the bearing 9. within 7. Because the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com