River snail shell removing machine

A technology of shelling machine and snail, which is applied in the fields of crustacean processing, slaughtering, food science, etc. It can solve the problems of uneven crushing and insufficient cleanness of shelling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

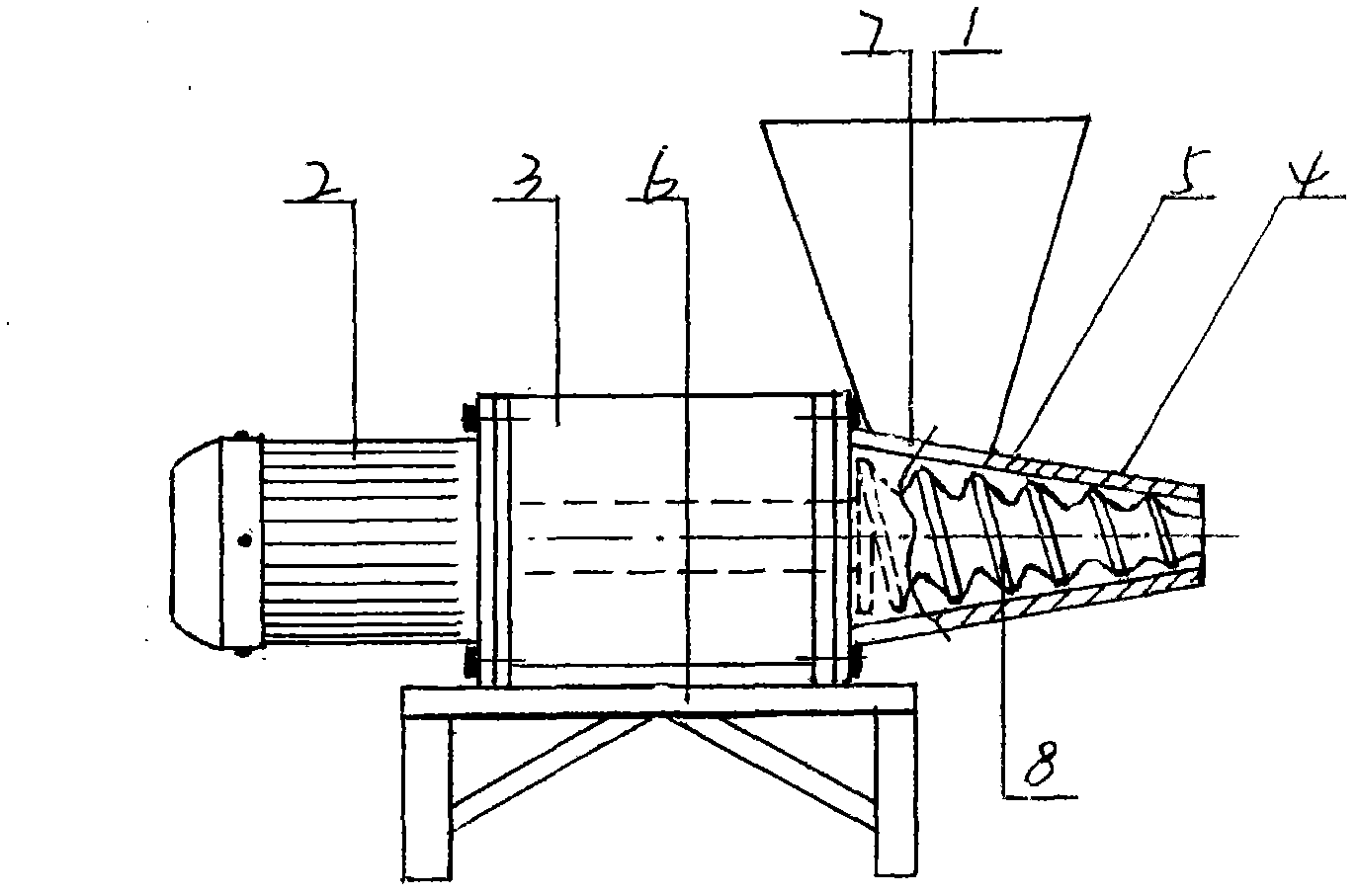

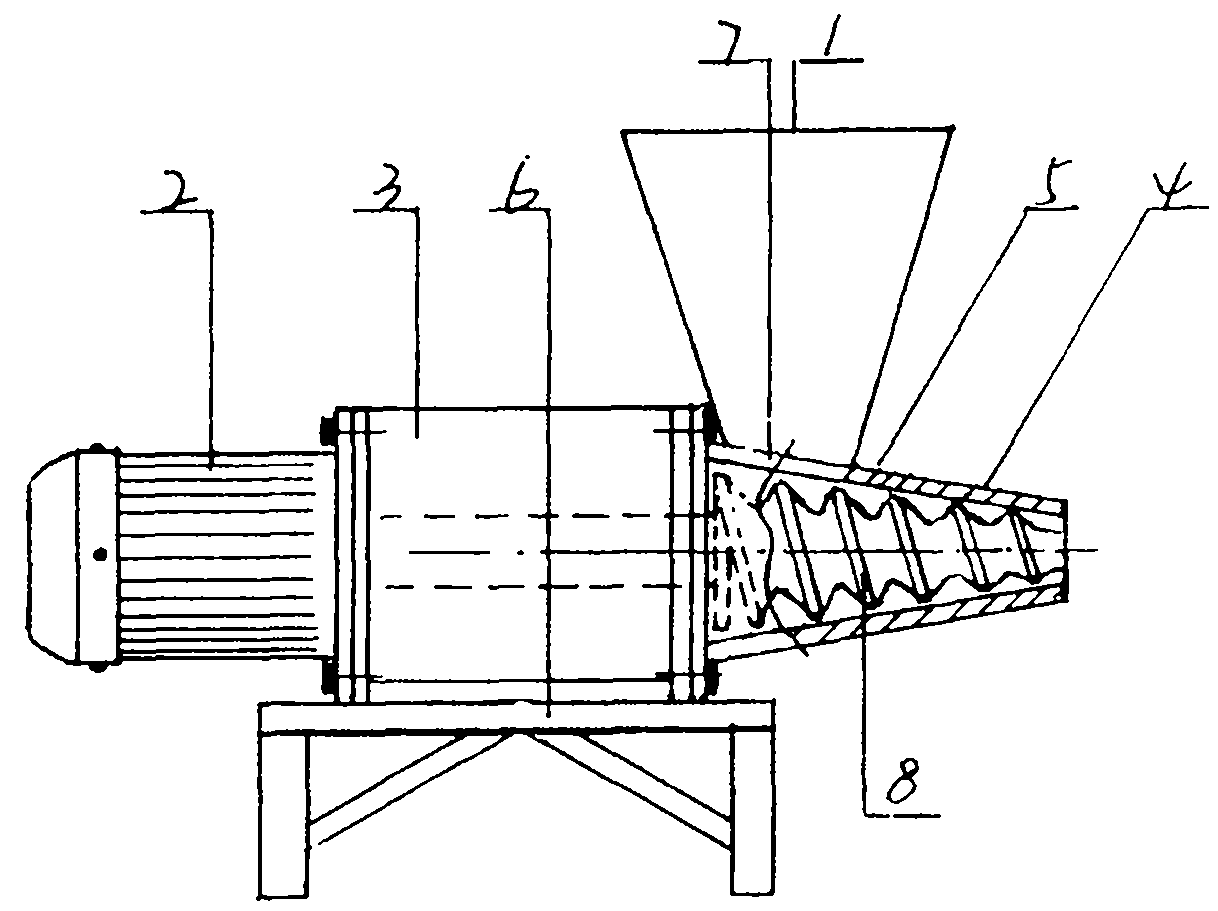

[0007] Such as figure 1 As shown, the structure of the snail shelling machine is composed of a funnel 1, a motor 2, a reducer 3, a screw shaft 4, a spiral tube 5, a support 6 and the like. A funnel mouth 7 is provided directly above the big head of the spiral tube 5, and the lower mouth of the funnel 1 is connected to the funnel mouth 7 as a whole. The shape of the funnel 1 is circular truncated or truncated truncated, and its effect is to hold the snails to be processed and to make the snails smoothly enter the spiral tube. The reducer 3 adopts a horizontal type, and the base of the reducer 3 and the support 6 are connected into one. Support 6 is a rectangular frame with four leg structures under it, which is used to support all parts weight above. The motor 2 is connected to the input shaft end of the reducer 3 , the motor 2 and the reducer 3 are connected into one body, and the motor 2 is used to provide power to the reducer 3 . The output shaft end of the speed reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com