Optimizing apparatus

An optimization device, carbon dioxide technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problem of large energy consumption, to achieve the effect of ensuring product quality and control optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0037] >

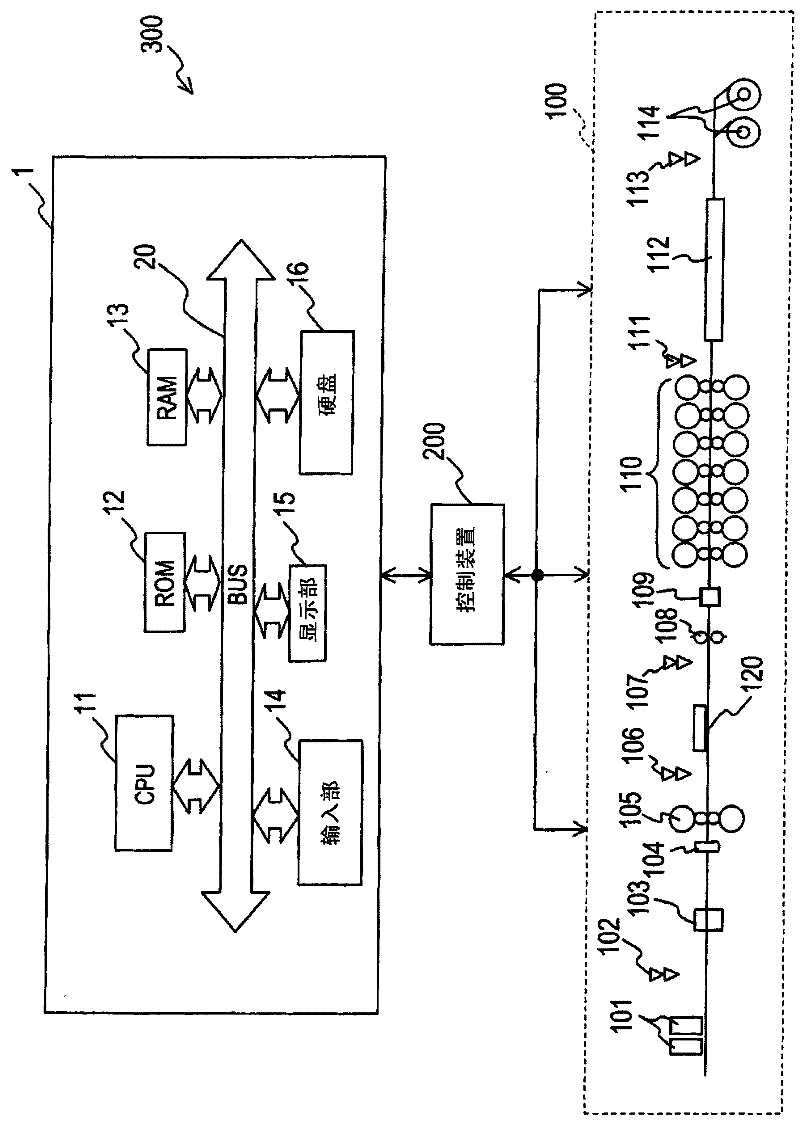

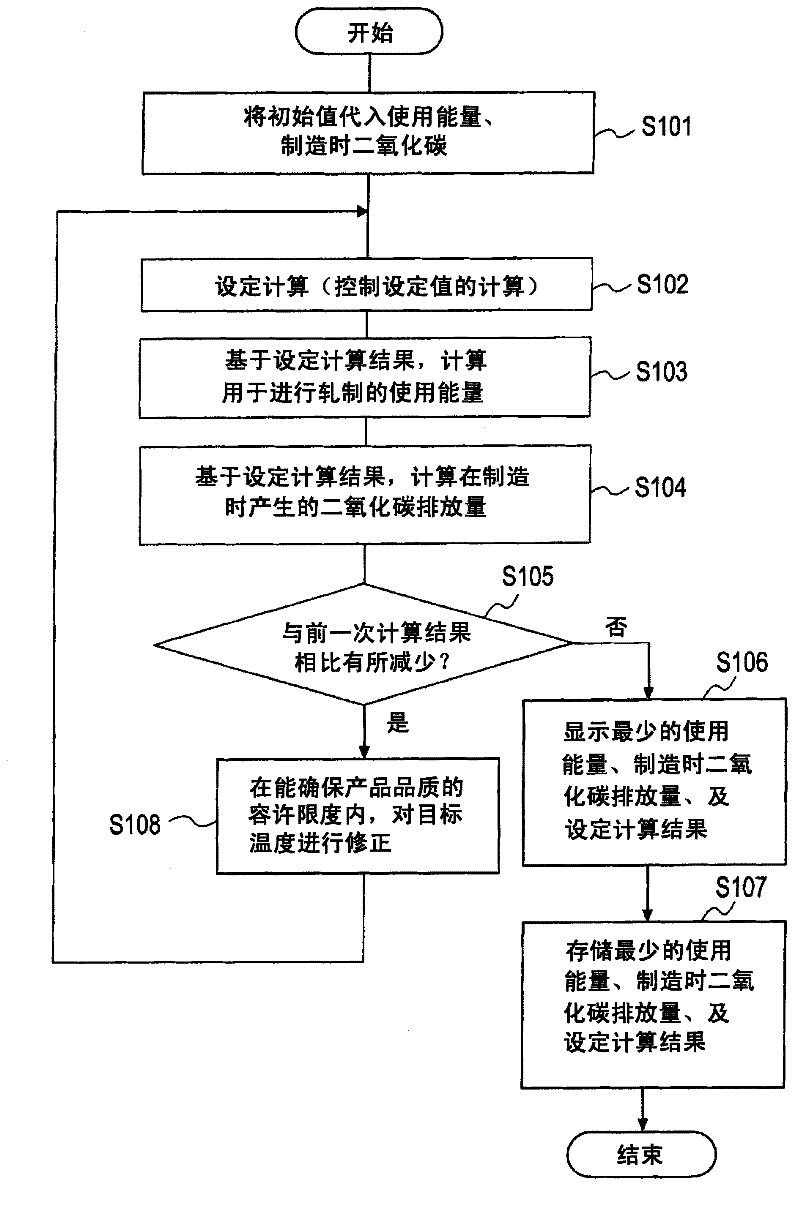

[0038] figure 1 It is a configuration diagram showing the configuration of a hot rolling system to which the optimization device according to Embodiment 1 of the present invention is applied.

[0039] Such as figure 1 As shown, the hot rolling system 300 includes the optimization device 1 related to Embodiment 1, the hot rolling device 100 for rolling the rolling material in a heated state, and the control device 200 for controlling the hot rolling device 100. The optimization device 1 is connected to the control device 200.

[0040] The hot rolling apparatus 100 includes a slab heating furnace 101 for heating a rolled material 120 by burning fossil fuels such as diesel or natural gas, a slab heating furnace outlet thermometer 102 for measuring the outlet temperature of the slab heating furnace 101, A high-pressure descaling unit 103 that sprays high-pressure water above and below the rolled material 120 to remove iron and phosphorus (scale) from the surface of t...

Embodiment approach 2

[0122] Next, an optimization device 1A according to Embodiment 2 of the present invention will be described.

[0123] The optimization device 1A according to Embodiment 2 and figure 1 The optimization device 1 according to the first embodiment shown is the same, and is connected to the control device 200 that controls the hot rolling device 100 .

[0124] Furthermore, optimization device 1A according to Embodiment 2 includes CPU 11A, ROM 12 , RAM 13 , input unit 14 , display unit 15 , and hard disk 16 . However, since the ROM 12 , RAM 13 , display unit 15 , and hard disk 16 are the same as those included in the optimization device 1 according to Embodiment 1, the configurations denoted by the same reference numerals will be omitted here.

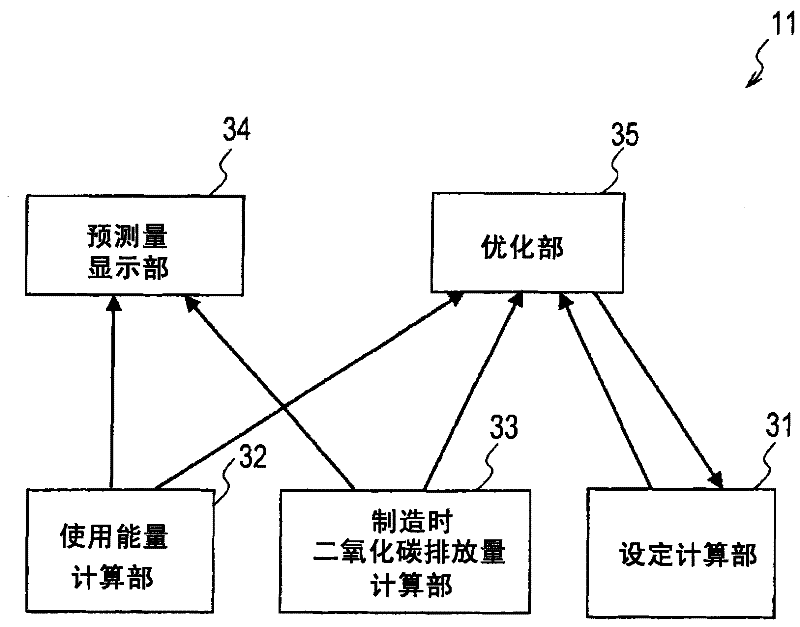

[0125] Figure 6 It is a configuration diagram showing the configuration of CPU 11A included in optimization device 1A according to Embodiment 2 of the present invention.

[0126] Such as Figure 6 As shown, the CPU 11 functionally inclu...

Embodiment approach 3

[0132] Next, an optimization device 1B according to Embodiment 3 of the present invention will be described.

[0133] The optimization device 1B related to Embodiment 3 and figure 1 The optimization device 1 according to the first embodiment shown is the same, and is connected to the control device 200 that controls the hot rolling device 100 .

[0134] Furthermore, optimization device 1B according to Embodiment 3 of the present invention includes CPU 11B, ROM 12 , RAM 13 , input unit 14 , display unit 15 , and hard disk 16 . However, since the ROM 12 , RAM 13 , input unit 14 , display unit 15 , and hard disk 16 are the same as those included in the optimization device 1 according to the first embodiment, the description thereof will be omitted.

[0135] Figure 7 It is a configuration diagram showing the configuration of the CPU 11B included in the optimization device 1B according to Embodiment 3 of the present invention.

[0136] Such as Figure 7 As shown, the CPU 11B f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com