Generation method of automatic optical detecting model diagram

A technology for automatic optical detection and detection of models, which is used in material analysis, measuring devices, scientific instruments, etc. by optical means, and can solve the problem of time-consuming procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

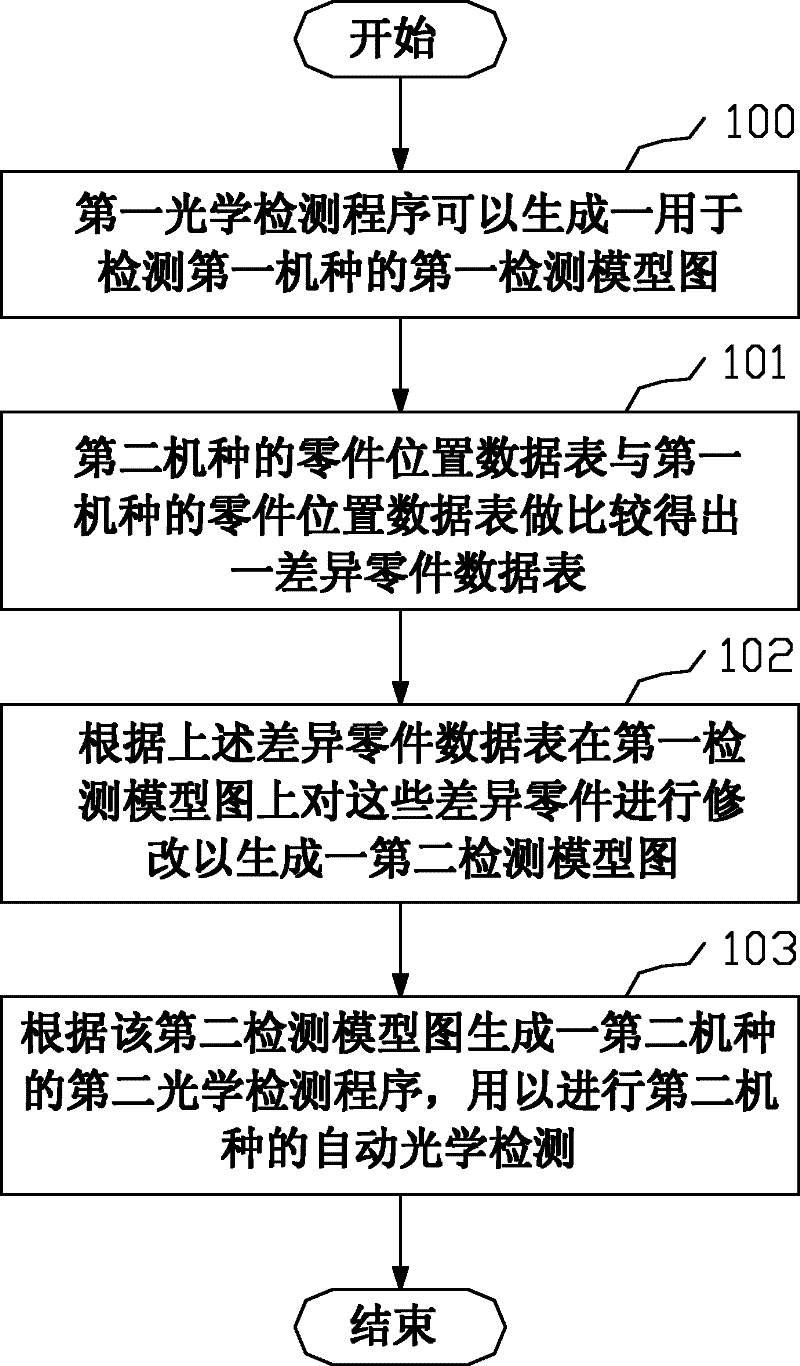

[0015] see figure 1 , figure 1 It is a method flowchart of a preferred embodiment of the method for generating an automatic optical inspection model diagram of the present invention.

[0016] The invention provides a method for generating an automatic optical inspection model diagram, which is carried out on the basis of a first optical inspection program, and the first optical inspection program can generate a first model for inspection of a first model Detection model diagram, the method is used for the generation of an optical detection model diagram of a second model similar to the first model, in this preferred embodiment, the method includes the following steps:

[0017] The first optical detection program can generate a first detection model diagram for detecting the first model (step 100);

[0018] The part position data table of the second model is compared with the part position data table of the first model to obtain a difference part data table (step 101);

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com