Cement production line material drying temperature control method and device adopting waste heat power generation

A technology of drying temperature and waste heat power generation, which is applied in cement production, drying, dryers, etc., can solve problems such as production decline, cement quality instability, and increased energy consumption of cement clinker, so as to maintain stable operation and improve Yield and quality, the effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

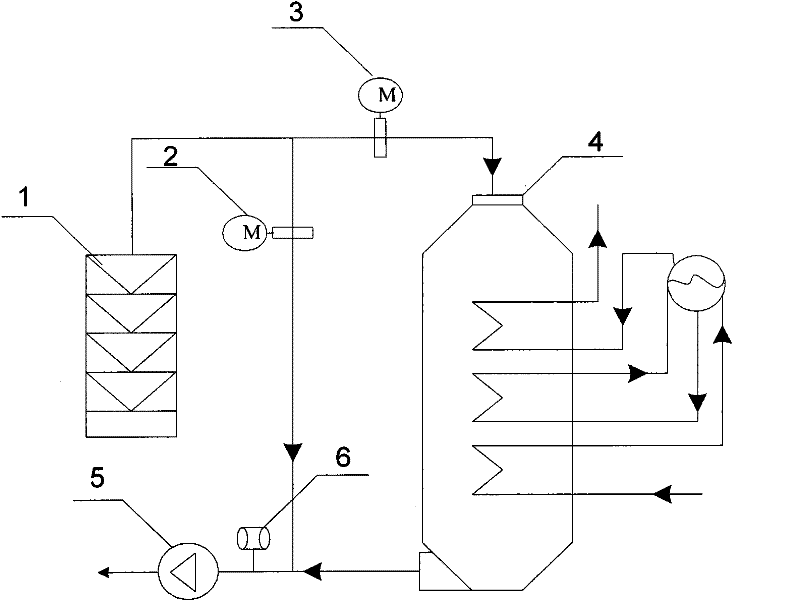

[0018] exist figure 1 In the process, the electric louver valve 2 is installed in the exhaust gas bypass pipeline at the kiln tail, the electric louver valve 3 is installed in the exhaust gas pipeline at the boiler inlet, and the temperature sensor 6 is installed at the inlet pipeline of the drying system at the kiln tail, and the temperature signal and the opening degree of the electric valve are input and output The signal is connected to the computer control system.

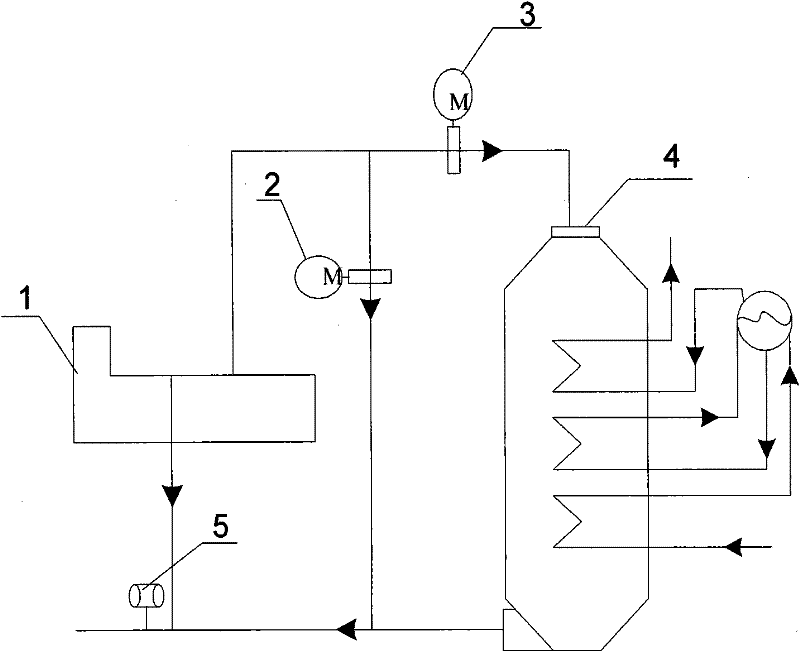

[0019] exist figure 2 In the process, an electric shutter valve 2 is installed in the waste gas bypass pipe of the kiln head, an electric shutter valve 3 is installed in the exhaust gas pipe at the boiler inlet, a temperature sensor 5 is installed at the inlet pipe of the kiln head material drying system, and the temperature signal and the opening degree of the electric valve are input, The output signal is connected to the computer control system.

[0020] image 3 Shown is the implementation of the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com