Coke oven coal gas purification apparatus

A purification device, a technology for coke oven gas, which is applied in the direction of combustible gas purification, combustible gas purification/transformation, selection of absorbing solid gas purification, etc. The frequency of downtime and maintenance of the cutter, clogging and other problems can reduce the frequency of continuous casting equipment and pressure maintenance, the purification effect is obvious, and the operation is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

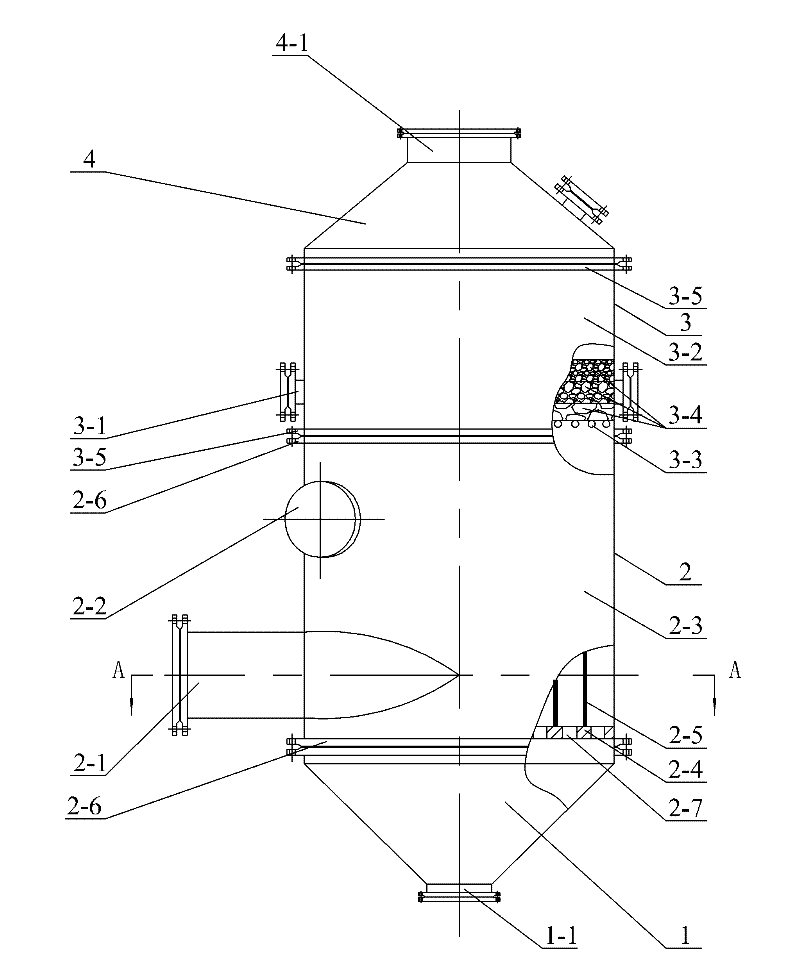

[0010] Specific implementation mode one: combine figure 1 Explain that the coke oven gas purification device of this embodiment includes a water storage bucket 1, a primary dehydration and decoking assembly 2, a secondary decoking assembly 3 and an upper cover 4; , The secondary decoking assembly 3 and the upper cover 4 are sealed and connected sequentially from bottom to top, the lower end of the water storage bucket 1 is provided with a water outlet 1-1, and the side wall of the primary dehydration and decoking assembly 2 is sequentially provided with a water outlet 1-1 from bottom to top. Purified gas inlet 2-1 and first manhole 2-2, second manhole 3-1 is provided on the side wall of secondary decoking component 3, and purified gas outlet 4-1 is provided on the top of upper cover 4.

specific Embodiment approach 2

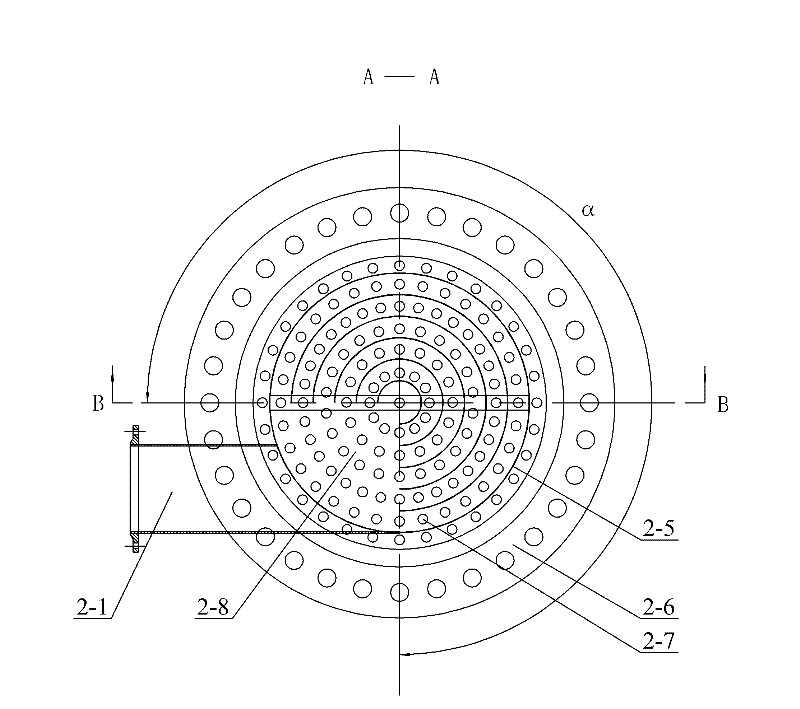

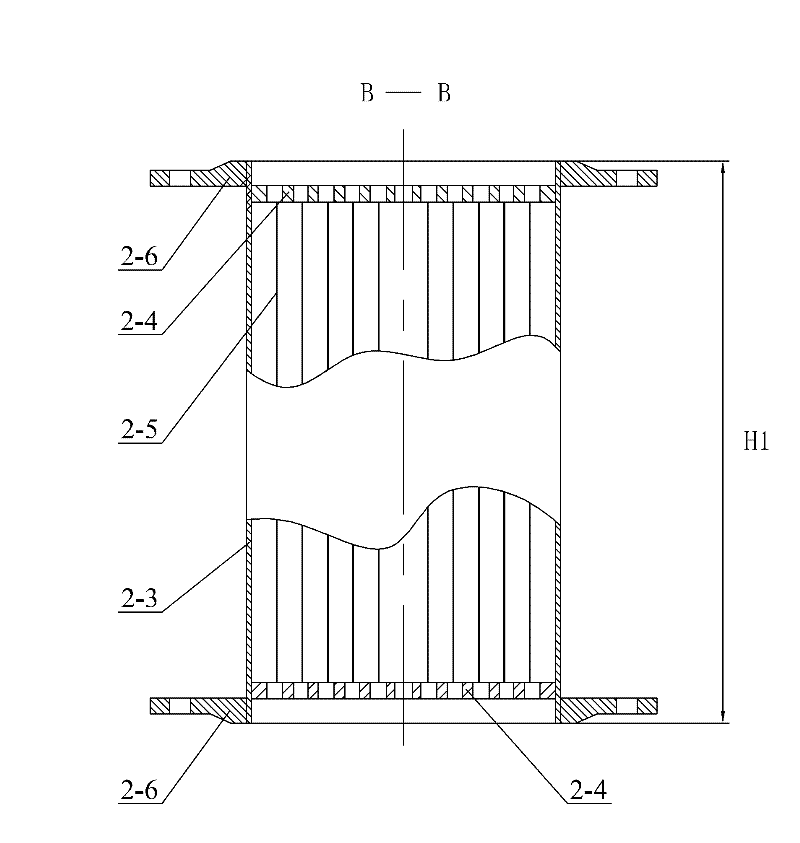

[0011] Specific implementation mode two: combination Figure 1-Figure 3 Explain that the primary dehydration and decoking assembly 2 of this embodiment includes a primary dehydration and decoking cylinder 2-3 and a primary cyclone assembly; the primary cyclone assembly includes two support plates 2-4, multi-layer, etc. Swirling flow plates 2-5 and two first flanges 2-6 arranged at intervals; two ends of the first-stage dehydration and decoking cylinder 2-3 are each fixedly fitted with a first flange 2-6, The lower end and the upper end of the first-stage dehydration and decoking cylinder 2-3 are respectively fixed with a support plate 2-4, and each support plate 2-4 is provided with several through holes 2-7 on the entire plate surface, multi-layer, etc. The swirl plates 2-5 arranged at intervals are arranged between the two support plates 2-4 in the first-stage dehydration and decoking cylinder body 2-3, and the two ends of the swirl plates 2-5 arranged at equal intervals in ...

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 and image 3 Note that the height H1 of the primary dehydration and decoking assembly 2 of this embodiment is 1800 mm; the outer diameter of the primary dehydration and decoking cylinder 2-3 is 1820×10 mm. This design can meet the requirements of gas purification. Others are the same as in the first or second embodiment.

[0013] Specific implementation mode four: combination figure 1 , Figure 4 and Figure 5 Explain that the secondary decoking assembly 3 of this embodiment includes a secondary decoking cylinder 3-2, a cylinder grate 3-3, three layers of coke filler filter adsorption layer 3-4 and two second flanges 3- 5. Both ends of the secondary decoking cylinder 3-2 are fixedly fitted with a second flange 3-5, and the lower end of the secondary decoking cylinder 3-2 is fixedly equipped with a cylinder grate 3-3, The cylinder grate 3-3 is provided with three layers of coke filler filter adsorption layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com