Oil pollution separator

A technology for oil pollution separation and separation screen, which is applied in liquid separation, separation methods, grease/oily substance/floating matter removal devices, etc., can solve the problems of sewer blockage, difficulty in water purification, and inability to comprehensively filter, to reduce difficulty and structure. Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

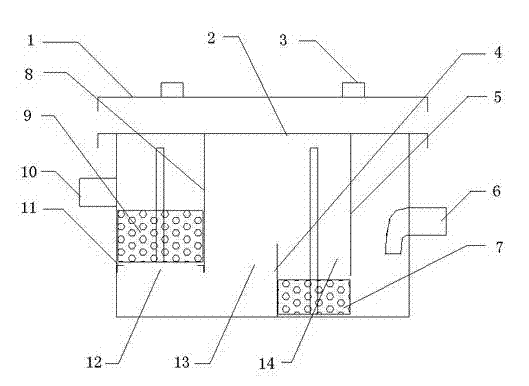

[0020] Such as figure 1 , 2 As shown, the oil separator includes a box body 2 and a cover 1, and the box body 2 is 250 cm high, which matches the height of a common sink, without remodeling the sink, which is convenient for the popularization and use of the oil separator; The box body 2 and the cover 1 are fastened by a set of press buckles 15, and a sealing strip 16 is provided at the bottom of the cover 1 to ensure the sealing between the cover 1 and the box body 2; 3 handles for easy lifting. Water inlet 10, water outlet 6 and liquid level pipe 17 are arranged on box body 2, water inlet 10 center line is apart from box body 2 bottom surface 170cm, water outlet 6 center line is apart from box body 2 bottom surface 130cm, water inlet 10 height is higher than The height of the water outlet 6, and the water outlet 6 extends into the box body 2 and is connected with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com