Brake having noise elimination function

A technology of brakes and brake pads, applied in the direction of the hoisting device, etc., can solve the problems of the armature moving distance becoming longer, the brake switch not functioning normally, and the collision sound becoming louder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, embodiments will be described in detail with reference to the drawings.

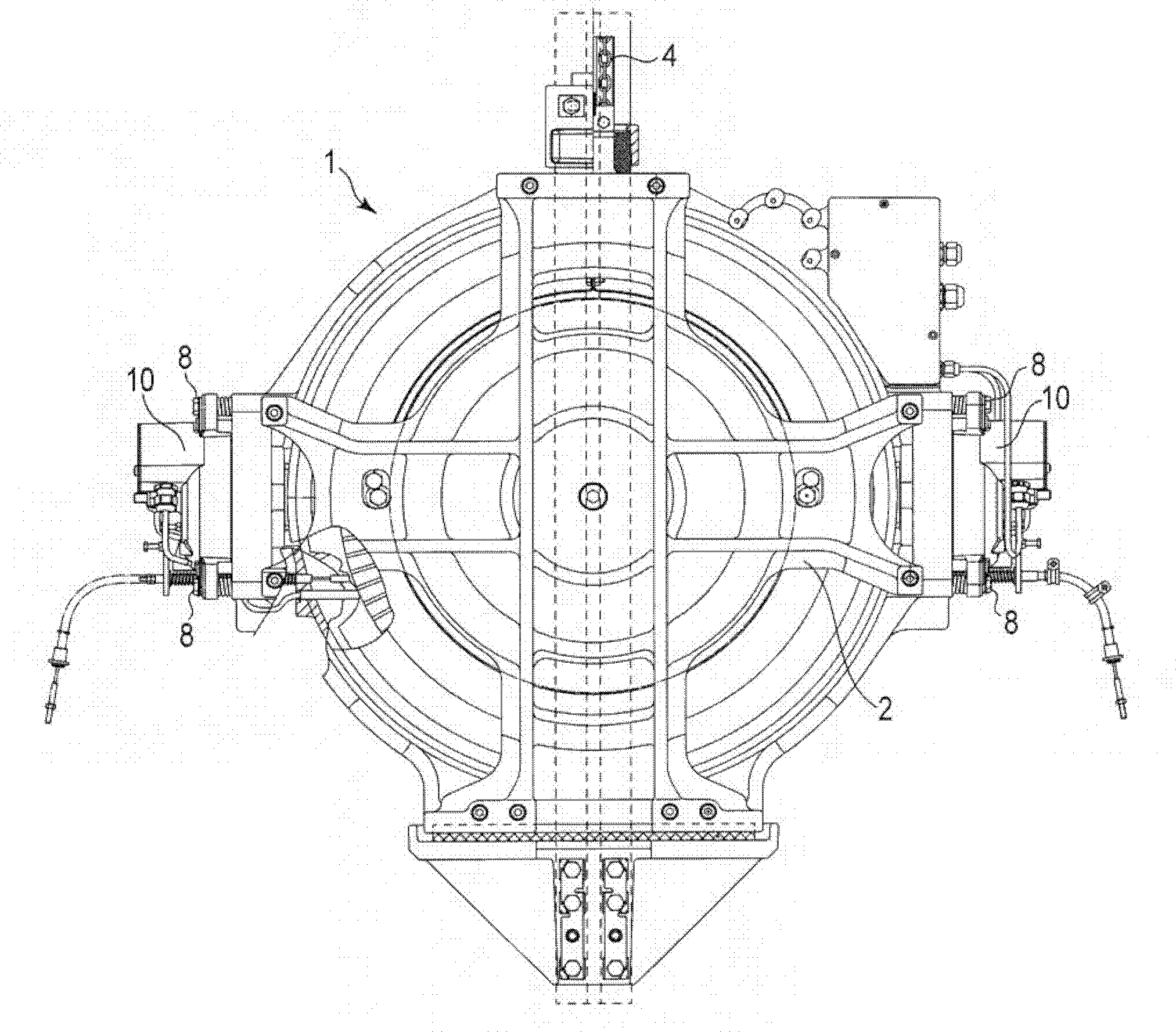

[0016] figure 1 It is the schematic diagram which looked at the hoisting machine 1 of the elevator of embodiment from the axial direction. The hoisting machine 1 is fixedly installed in a hoistway (not shown) via a cross-shaped motor casing 2 . And the hoisting machine 1 winds up the rope 4 connected to the cage|basket (not shown) arrange|positioned so that it can move up and down in a hoistway.

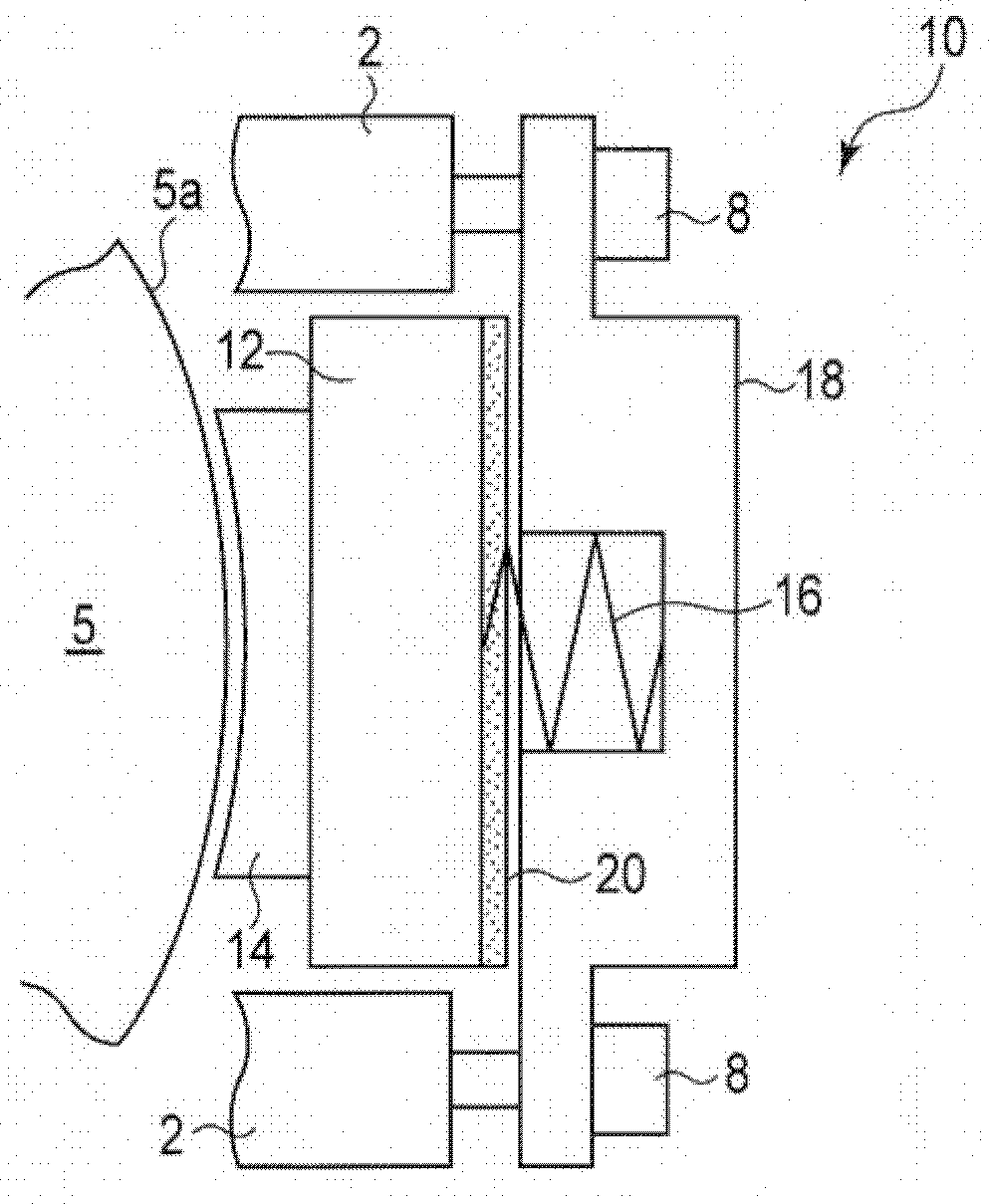

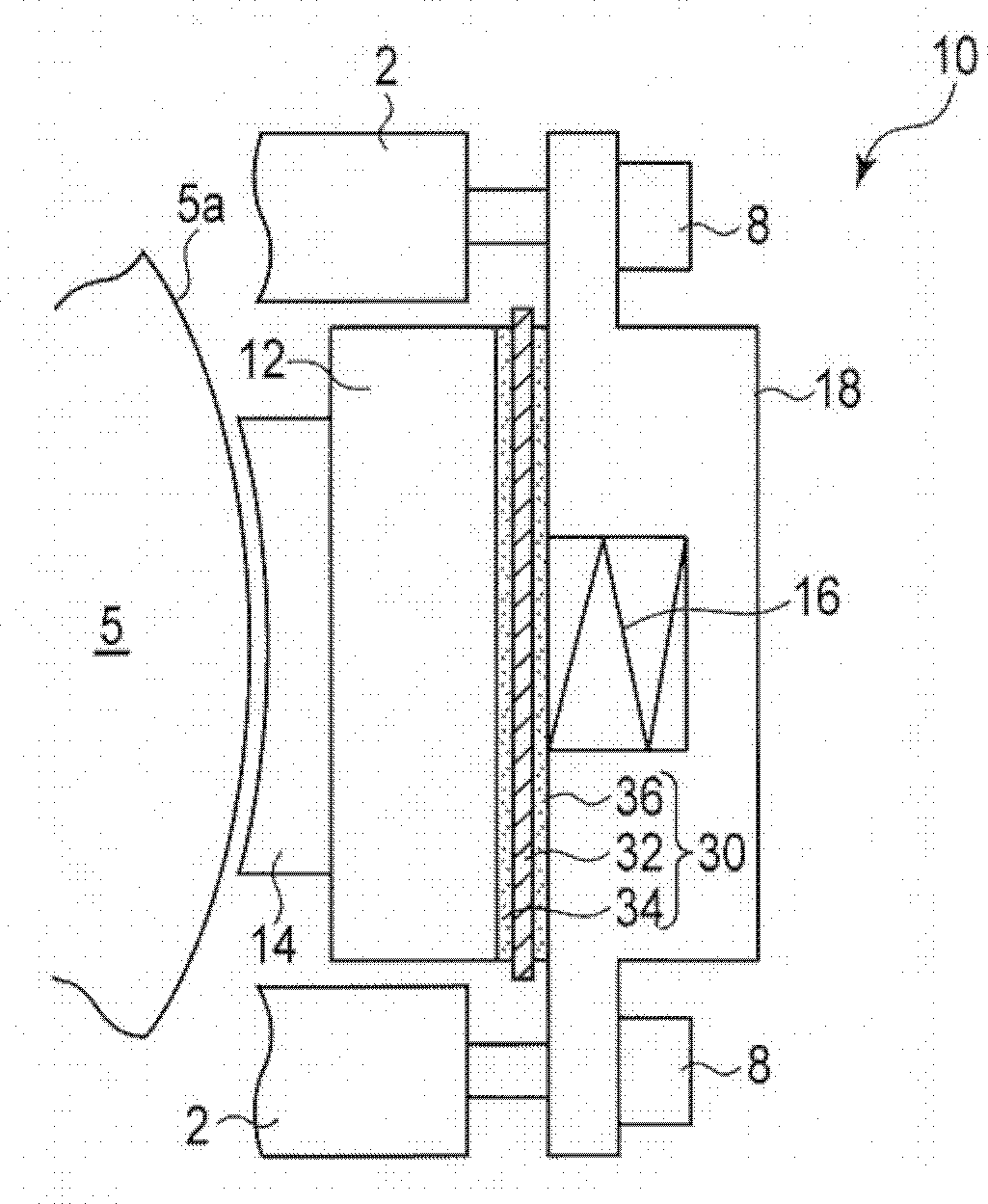

[0017] This hoisting machine 1 is provided with two brakes 10 and 10 which act on the drum 5 to be described later which is fixed to the rotating shaft. The two brakes 10 are located at the center of the rotation axis of the hoist 1. figure 1 are arranged in a symmetrical position. Each brake 10 is fixed to the motor case 2 using a plurality of screws 8 . In addition, since these two brakes 10 have substantially the same structure, here, only the brake 10 on the right side in the figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com