Fastening spanner for large-diameter and high-strength bolt and use method thereof

A high-strength bolt, large-diameter technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of manual screwing difficulty and danger, difficult screwing, and hidden dangers of operation safety, etc., and it is easy to guarantee the construction quality. , the effect of high construction efficiency and small safety risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

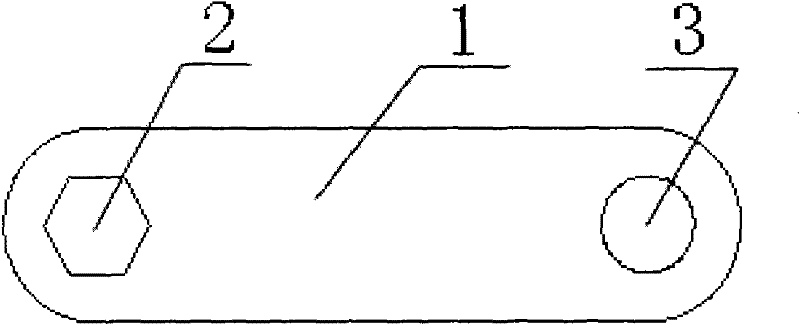

[0020] A fastening wrench for large-diameter high-strength bolts, such as Figure 1 ~ Figure 3 As shown, the specific structure is: including the base plate 1 and the sleeve 4, one end of the base plate 1 is provided with a nut hole 2, the nut hole 2 is a regular hexagonal hole, and the other end of the base plate 1 is provided with a connecting hole 3 for connecting Hole 3 is a circular hole. Both ends of the bottom plate 1 are semicircular, the distance from the center of the nut hole 2 to the outermost edge of the bottom plate 1 at the end of the nut hole 2 is equal to the distance from the opposite side of the nut hole 2, and the distance between the center of the connecting hole 3 and the end of the connecting hole 3 The distance from the outermost edge of the bottom plate 1 is equal to the diameter of the connecting hole 3 . The inner diameter of the sleeve 4 is 105% to 120% of the width of the bottom plate 1, which is 110% in this embodiment, and the sleeve 4 is set ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com