Inner cavity cleaning clamp for high-pressure oil pipe

A technology for high-pressure oil pipes and cleaning fixtures, used in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of high pressure, high sealing requirements between cleaning equipment and oil pipes, etc., to achieve convenient use and ensure cleanliness High degree of requirements, simple and convenient loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings and embodiments.

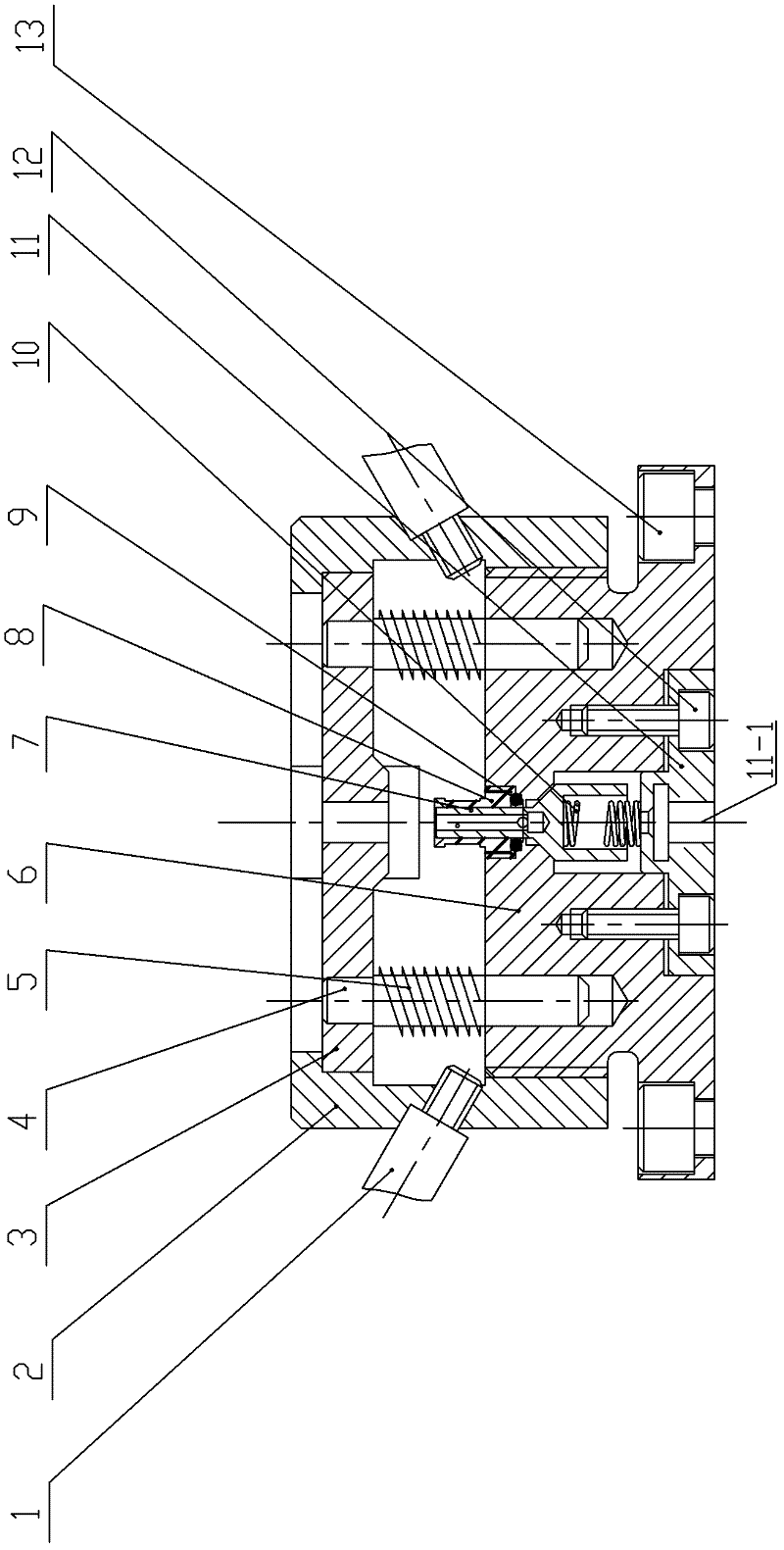

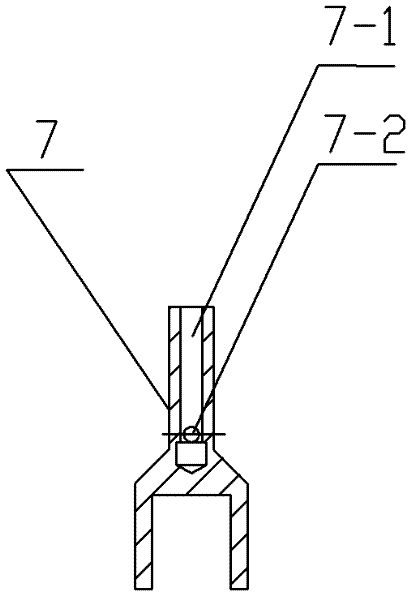

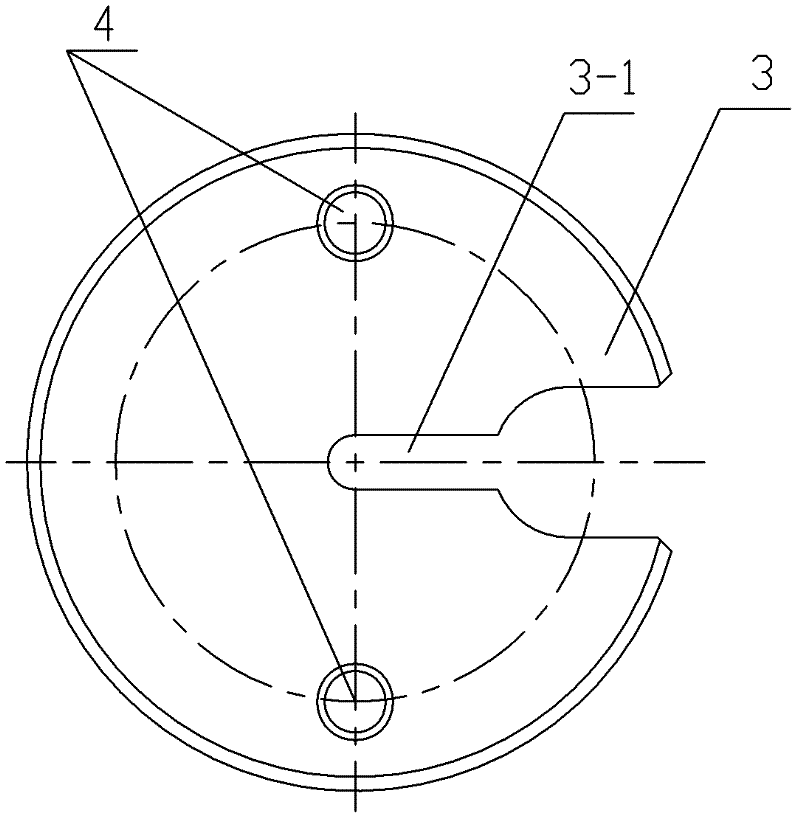

[0014] Such as figure 1 , as shown in 2, the high-pressure oil pipe inner cavity cleaning fixture includes a fixture body 6, a spool 7 is located at the center of the fixture body 6, the upper end of the spool 7 is covered with a joint 8, and the lower part of the joint 8 is threaded with the fixture body 6. A sealing ring 9 is sheathed around the waist of the valve core 7, and the sealing ring 9 is located in the gap between the lower part of the joint 8 and the fixture body. There is a gap between the lower part of the valve core 7 and the fixture body 6, and a bottom plate 11 is provided under the valve core 7, on which one end of the first compression spring 10 (1.5*8*15GB2089) is fixed, and the other end of the first compression spring 10 is Support the lower end of the spool 7. The bottom plate 11 is fixed to the main body 6 by M6 socket head cap screws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com