Excircle glue dispenser of full-automatic filter

A round glue injection machine and filter technology, which is applied in the field of automatic filter outer circle glue injection machines, can solve problems such as hot melt glue gun burns, uneven application, safety accidents, etc., and achieve low production efficiency , to overcome the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

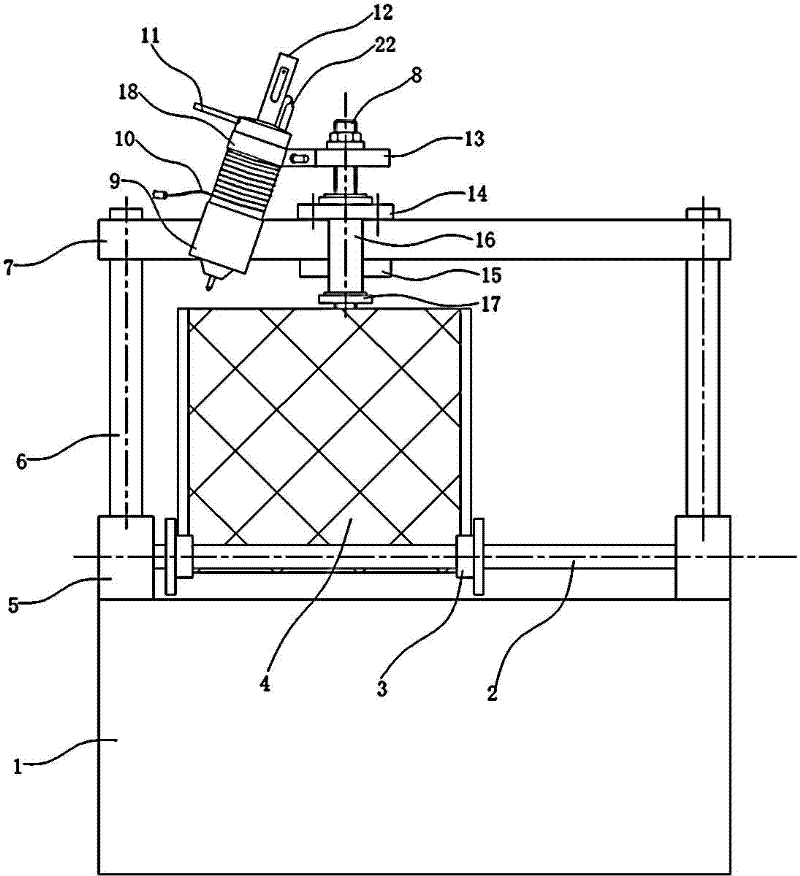

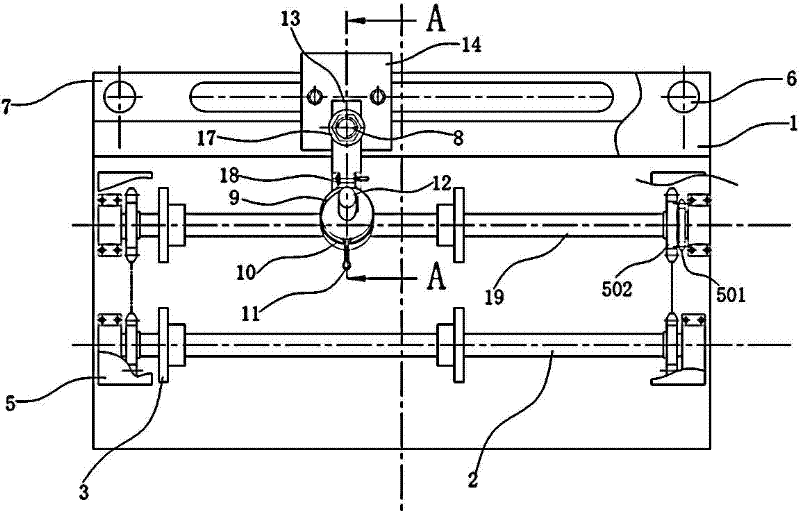

[0021] Such as figure 1 , image 3 As shown, what the present invention provides is a kind of automatic filter outer circular glue injection device, which includes the following parts:

[0022] 1. Rack part:

[0023] Such as figure 1 , figure 2 As shown, the frame 1 is provided with a workbench, and two support rods 6 are arranged on the other side, and a support plate 7 is connected to the two support rods 6 .

[0024] 2. Filter rotating device:

[0025] Such as figure 1 , image 3 As shown, a protective cover 5 is respectively arranged at both ends of the worktable of the frame 1, and a driving roller 19 and a driven roller 2 are arranged on the workbench between the two protective covers. The two rollers are arranged in parallel horizontally, and the two rollers The middle part is respectively connected with two positioning wheels 3, and every two positioning wheels are symmetrically arranged to block the two ends of the filter 4; four driven sprockets 502 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com